Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

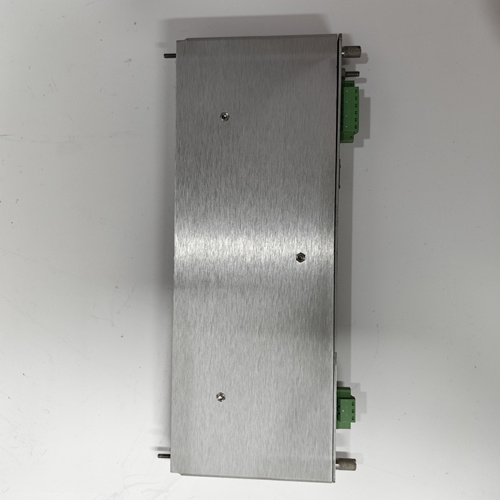

Bently Nevada 330102-00-28-10-02-05 3300 XL 8 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330102-00-28-10-02-05

Product Type:3300 XL 8 mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:75

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-28-10-02-05 is part of the 3300 XL 8 mm Proximity Probe series, designed for precise non-contact measurement of shaft position and vibration in industrial machinery. This probe is integral to the 3300 XL Proximity Transducer System, offering high performance and reliability in monitoring applications.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 330102-00-28-10-02-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Material | Polyphenylene sulfide |

| Case Material | AISI 303 or 304 Stainless Steel |

| Cable Insulation | Fluoroethylene propylene (FEP) |

| Operating Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Total Length | 1 m |

| Weight | 0.323 kg |

| Protection Rating | IP67 (Dust and water-resistant) |

| Operating Voltage | 12 to 28 V DC |

| Output Signal | Proportional voltage signal |

| Measurement Range | Up to 2 mm |

| Frequency Response | Up to 50 kHz |

Applications

-

Rotating Machinery Monitoring: Measures shaft position and vibration in turbines, compressors, and motors to detect misalignment, imbalance, or other mechanical issues.

-

Thrust Position Measurement: Monitors axial displacement in thrust bearings, ensuring machinery operates within specified parameters.

-

Eccentricity Measurement: Assesses the roundness of rotating shafts, crucial for maintaining equipment integrity.

-

Phase Reference (Keyphasor) Signals: Provides timing references for vibration analysis and balancing.

Advantages

-

High Precision: Delivers accurate measurements essential for effective machinery diagnostics.

-

Robust Construction: Stainless steel casing and FEP cable insulation ensure durability in harsh industrial environments.

-

Wide Temperature Range: Operates effectively across a broad temperature spectrum, suitable for various industrial settings.

-

Interchangeability: Compatible with other 3300 series components, facilitating easy system integration and upgrades.

-

Compliance with Standards: Meets API 670 standards for mechanical configuration and performance.

Frequently Asked Questions (FAQ)

-

What is the primary function of the 330102-00-28-10-02-05 probe?

It measures shaft position and vibration in rotating machinery for condition monitoring and diagnostics.

-

Is this probe compatible with other Bently Nevada systems?

Yes, it’s designed for use with the 3300 XL Proximity Transducer System and is backward-compatible with previous 3300 series components.

-

What is the operating temperature range of this probe?

It operates effectively between -51°C to +177°C (-60°F to +350°F).

-

Can this probe be used in hazardous environments?

Yes, it meets various hazardous area classifications; refer to the product manual for specific certifications.

-

What type of output signal does the probe provide?

It provides a voltage signal proportional to the measured displacement.

-

How is the probe installed?

It’s typically mounted near the rotating shaft using appropriate brackets and hardware, ensuring correct alignment and spacing.

-

Does the probe require calibration?

While it comes factory-calibrated, periodic verification is recommended to maintain measurement accuracy.

-

What maintenance is required for this probe?

Regular inspections for physical damage and cleanliness are advised to ensure optimal performance.

-

Is the probe resistant to environmental contaminants?

Yes, its IP67 rating ensures protection against dust and water ingress.

-

Is this probe compatible with older Bently Nevada monitoring systems?

Yes, it is designed to work with the 3300 XL Proximity Transducer System and is backward-compatible with some older 3300 series systems.

Bently Nevada 330102-00-28-10-02-05 3300 XL 8 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330102-00-28-10-02-05

Product Type:3300 XL 8 mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:75

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-28-10-02-05 is part of the 3300 XL 8 mm Proximity Probe series, designed for precise non-contact measurement of shaft position and vibration in industrial machinery. This probe is integral to the 3300 XL Proximity Transducer System, offering high performance and reliability in monitoring applications.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 330102-00-28-10-02-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Material | Polyphenylene sulfide |

| Case Material | AISI 303 or 304 Stainless Steel |

| Cable Insulation | Fluoroethylene propylene (FEP) |

| Operating Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Total Length | 1 m |

| Weight | 0.323 kg |

| Protection Rating | IP67 (Dust and water-resistant) |

| Operating Voltage | 12 to 28 V DC |

| Output Signal | Proportional voltage signal |

| Measurement Range | Up to 2 mm |

| Frequency Response | Up to 50 kHz |

Applications

-

Rotating Machinery Monitoring: Measures shaft position and vibration in turbines, compressors, and motors to detect misalignment, imbalance, or other mechanical issues.

-

Thrust Position Measurement: Monitors axial displacement in thrust bearings, ensuring machinery operates within specified parameters.

-

Eccentricity Measurement: Assesses the roundness of rotating shafts, crucial for maintaining equipment integrity.

-

Phase Reference (Keyphasor) Signals: Provides timing references for vibration analysis and balancing.

Advantages

-

High Precision: Delivers accurate measurements essential for effective machinery diagnostics.

-

Robust Construction: Stainless steel casing and FEP cable insulation ensure durability in harsh industrial environments.

-

Wide Temperature Range: Operates effectively across a broad temperature spectrum, suitable for various industrial settings.

-

Interchangeability: Compatible with other 3300 series components, facilitating easy system integration and upgrades.

-

Compliance with Standards: Meets API 670 standards for mechanical configuration and performance.

Frequently Asked Questions (FAQ)

-

What is the primary function of the 330102-00-28-10-02-05 probe?

It measures shaft position and vibration in rotating machinery for condition monitoring and diagnostics.

-

Is this probe compatible with other Bently Nevada systems?

Yes, it’s designed for use with the 3300 XL Proximity Transducer System and is backward-compatible with previous 3300 series components.

-

What is the operating temperature range of this probe?

It operates effectively between -51°C to +177°C (-60°F to +350°F).

-

Can this probe be used in hazardous environments?

Yes, it meets various hazardous area classifications; refer to the product manual for specific certifications.

-

What type of output signal does the probe provide?

It provides a voltage signal proportional to the measured displacement.

-

How is the probe installed?

It’s typically mounted near the rotating shaft using appropriate brackets and hardware, ensuring correct alignment and spacing.

-

Does the probe require calibration?

While it comes factory-calibrated, periodic verification is recommended to maintain measurement accuracy.

-

What maintenance is required for this probe?

Regular inspections for physical damage and cleanliness are advised to ensure optimal performance.

-

Is the probe resistant to environmental contaminants?

Yes, its IP67 rating ensures protection against dust and water ingress.

-

Is this probe compatible with older Bently Nevada monitoring systems?

Yes, it is designed to work with the 3300 XL Proximity Transducer System and is backward-compatible with some older 3300 series systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...