Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

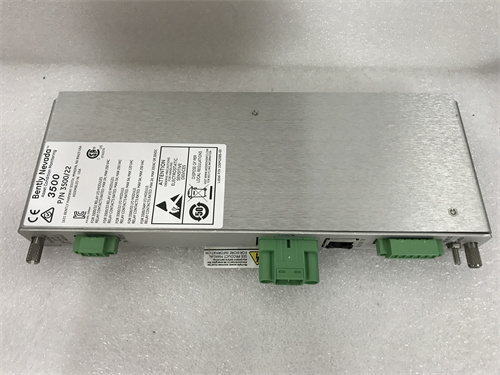

Bently Nevada 170133-090-00 3300 Internal Dual Proximitor Module

Manufacturer:Bently Nevada

Product Number:170133-090-00

Product Type:3300 Internal Dual Proximitor Module

Origin:USA

Dimensions:126.9 x 21.6 x 105.3 mm

Weight:0.32 kg

Views:99

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 170133-090-00 3300 Internal Dual Proximitor Module is a high-precision signal conditioning module designed for rotor vibration and position monitoring in industrial machinery. As a part of the 3300 Machinery Protection System, this module provides reliable and accurate proximity probe signal processing, converting raw sensor inputs into usable analog outputs for machinery protection and condition monitoring.

The dual proximitor design allows for simultaneous processing of two independent proximity probes, making it suitable for applications requiring redundancy, differential measurements, or dual-channel monitoring. Built with industrial-grade components, the module ensures high signal fidelity, low noise, and long-term stability, even in environments with high vibration, electrical noise, or temperature fluctuations.

This module is widely used in turbomachinery, generators, compressors, and pumps, enabling predictive maintenance, fault detection, and protection against catastrophic failures.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 170133-090-00 |

| Type | 3300 Internal Dual Proximitor Module |

| Function | Signal conditioning for dual proximity probes |

| Number of Channels | 2 independent channels |

| Output Signal | 4–20 mA or ±10 V analog (configurable) |

| Excitation Voltage | 8 V DC for proximity probes |

| Frequency Response | 0–10 kHz typical |

| Signal Linearity | ±0.25% full scale |

| Input Impedance | >1 MΩ |

| Operating Temperature | -40 to 70 °C |

| Storage Temperature | -55 to 85 °C |

| Relative Humidity | 5–95%, non-condensing |

| Mounting | Module slot within 3300 series rack |

| Dimensions (W x H x D) | 126.9 x 21.6 x 105.3 mm |

| Weight | 0.32 kg |

| Compliance | IEC 61010, CE, UL |

Product Applications

The 170133-090-00 dual proximitor module is used in industrial machinery monitoring:

-

Turbomachinery – Monitors rotor vibration, axial position, and orbit in turbines, compressors, and generators.

-

Pumps and Motors – Provides dual-channel vibration measurement for critical pumps and motor shafts.

-

Redundant Monitoring – Supports dual-channel operation for safety-critical machinery requiring continuous monitoring.

-

Oil & Gas – Used in compressors, turbines, and rotating equipment in refineries and offshore platforms.

-

Power Generation – Monitors generator and steam turbine rotors in power plants.

-

Industrial Automation – Integrates with 3300 Series racks for machinery protection and condition-based maintenance.

Product Advantages

-

Dual Channel Capability – Supports two independent proximity probes for redundancy or differential measurement.

-

High Accuracy – Maintains ±0.25% full-scale linearity for precise vibration and position measurements.

-

Stable Excitation Voltage – 8 V DC excitation ensures consistent probe performance.

-

Robust Design – Industrial-grade components withstand vibration, temperature variation, and electrical noise.

-

Easy Integration – Compatible with 3300 series racks, simplifying installation and maintenance.

-

Configurable Output – Supports 4–20 mA or ±10 V analog outputs for flexible system integration.

-

Standards Compliant – Meets IEC, CE, and UL safety and performance standards.

FAQ

-

What is the main function of the 170133-090-00 module?

It conditions signals from two proximity probes, converting raw inputs into reliable analog outputs for machinery protection and monitoring.

-

How many channels does the module support?

The module supports two independent channels, allowing simultaneous dual-probe monitoring or redundancy.

-

What types of output signals are available?

It provides configurable analog outputs: 4–20 mA or ±10 V, suitable for integration with monitoring and control systems.

-

What is the excitation voltage for the proximity probes?

The module provides a stable 8 V DC excitation to each connected probe.

-

Is it compatible with the 3300 Series rack?

Yes, it is designed to fit directly into standard 3300 series racks for seamless integration.

-

What is the frequency response of the module?

It operates from 0 Hz up to 10 kHz, supporting high-speed rotor vibration monitoring.

-

What is the linearity accuracy of the output signal?

The output signal maintains ±0.25% full-scale linearity, ensuring precise measurement of rotor position and vibration.

-

Can it operate in harsh industrial environments?

Yes, it is rated for -40 to 70 °C and 5–95% relative humidity (non-condensing).

-

Does it support redundant measurements?

Yes, dual channels can be used for redundancy, critical for safety and continuous monitoring applications.

-

What standards does the module comply with?

It complies with IEC 61010, CE, and UL, ensuring safety and reliable operation in industrial applications.

Bently Nevada 170133-090-00 3300 Internal Dual Proximitor Module

Manufacturer:Bently Nevada

Product Number:170133-090-00

Product Type:3300 Internal Dual Proximitor Module

Origin:USA

Dimensions:126.9 x 21.6 x 105.3 mm

Weight:0.32 kg

Views:99

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 170133-090-00 3300 Internal Dual Proximitor Module is a high-precision signal conditioning module designed for rotor vibration and position monitoring in industrial machinery. As a part of the 3300 Machinery Protection System, this module provides reliable and accurate proximity probe signal processing, converting raw sensor inputs into usable analog outputs for machinery protection and condition monitoring.

The dual proximitor design allows for simultaneous processing of two independent proximity probes, making it suitable for applications requiring redundancy, differential measurements, or dual-channel monitoring. Built with industrial-grade components, the module ensures high signal fidelity, low noise, and long-term stability, even in environments with high vibration, electrical noise, or temperature fluctuations.

This module is widely used in turbomachinery, generators, compressors, and pumps, enabling predictive maintenance, fault detection, and protection against catastrophic failures.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 170133-090-00 |

| Type | 3300 Internal Dual Proximitor Module |

| Function | Signal conditioning for dual proximity probes |

| Number of Channels | 2 independent channels |

| Output Signal | 4–20 mA or ±10 V analog (configurable) |

| Excitation Voltage | 8 V DC for proximity probes |

| Frequency Response | 0–10 kHz typical |

| Signal Linearity | ±0.25% full scale |

| Input Impedance | >1 MΩ |

| Operating Temperature | -40 to 70 °C |

| Storage Temperature | -55 to 85 °C |

| Relative Humidity | 5–95%, non-condensing |

| Mounting | Module slot within 3300 series rack |

| Dimensions (W x H x D) | 126.9 x 21.6 x 105.3 mm |

| Weight | 0.32 kg |

| Compliance | IEC 61010, CE, UL |

Product Applications

The 170133-090-00 dual proximitor module is used in industrial machinery monitoring:

-

Turbomachinery – Monitors rotor vibration, axial position, and orbit in turbines, compressors, and generators.

-

Pumps and Motors – Provides dual-channel vibration measurement for critical pumps and motor shafts.

-

Redundant Monitoring – Supports dual-channel operation for safety-critical machinery requiring continuous monitoring.

-

Oil & Gas – Used in compressors, turbines, and rotating equipment in refineries and offshore platforms.

-

Power Generation – Monitors generator and steam turbine rotors in power plants.

-

Industrial Automation – Integrates with 3300 Series racks for machinery protection and condition-based maintenance.

Product Advantages

-

Dual Channel Capability – Supports two independent proximity probes for redundancy or differential measurement.

-

High Accuracy – Maintains ±0.25% full-scale linearity for precise vibration and position measurements.

-

Stable Excitation Voltage – 8 V DC excitation ensures consistent probe performance.

-

Robust Design – Industrial-grade components withstand vibration, temperature variation, and electrical noise.

-

Easy Integration – Compatible with 3300 series racks, simplifying installation and maintenance.

-

Configurable Output – Supports 4–20 mA or ±10 V analog outputs for flexible system integration.

-

Standards Compliant – Meets IEC, CE, and UL safety and performance standards.

FAQ

-

What is the main function of the 170133-090-00 module?

It conditions signals from two proximity probes, converting raw inputs into reliable analog outputs for machinery protection and monitoring.

-

How many channels does the module support?

The module supports two independent channels, allowing simultaneous dual-probe monitoring or redundancy.

-

What types of output signals are available?

It provides configurable analog outputs: 4–20 mA or ±10 V, suitable for integration with monitoring and control systems.

-

What is the excitation voltage for the proximity probes?

The module provides a stable 8 V DC excitation to each connected probe.

-

Is it compatible with the 3300 Series rack?

Yes, it is designed to fit directly into standard 3300 series racks for seamless integration.

-

What is the frequency response of the module?

It operates from 0 Hz up to 10 kHz, supporting high-speed rotor vibration monitoring.

-

What is the linearity accuracy of the output signal?

The output signal maintains ±0.25% full-scale linearity, ensuring precise measurement of rotor position and vibration.

-

Can it operate in harsh industrial environments?

Yes, it is rated for -40 to 70 °C and 5–95% relative humidity (non-condensing).

-

Does it support redundant measurements?

Yes, dual channels can be used for redundancy, critical for safety and continuous monitoring applications.

-

What standards does the module comply with?

It complies with IEC 61010, CE, and UL, ensuring safety and reliable operation in industrial applications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...