Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

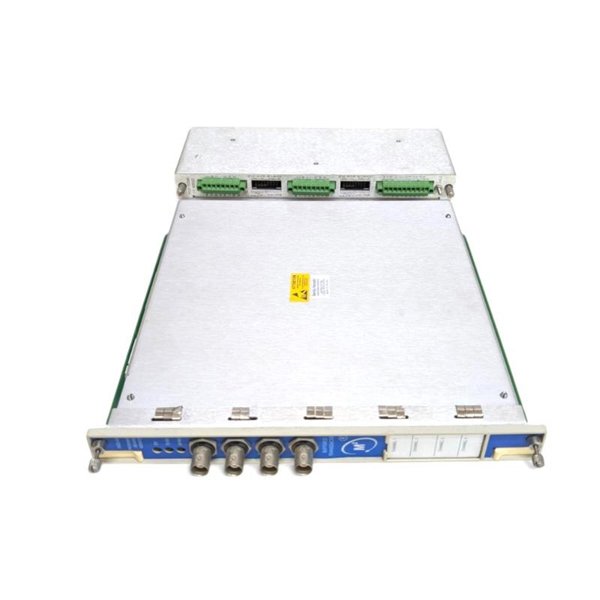

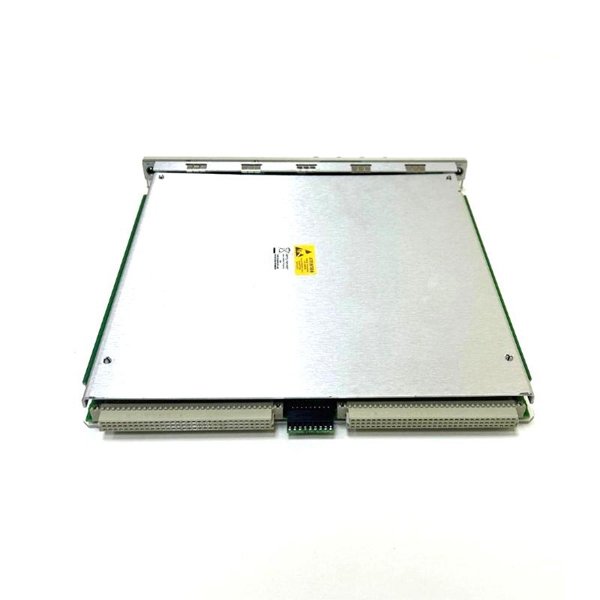

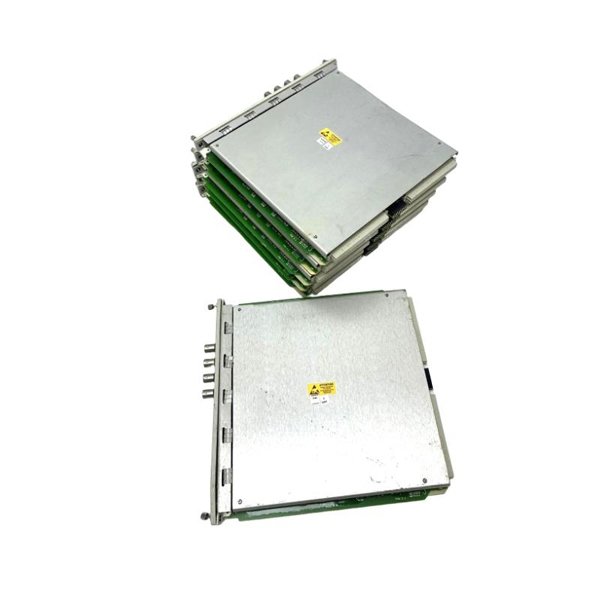

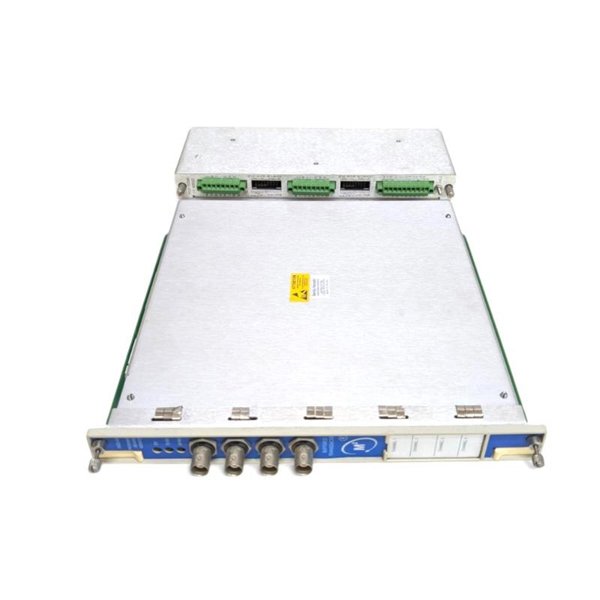

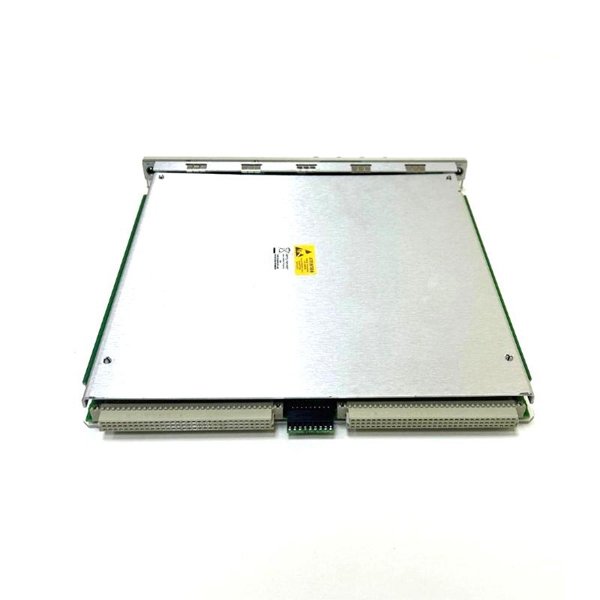

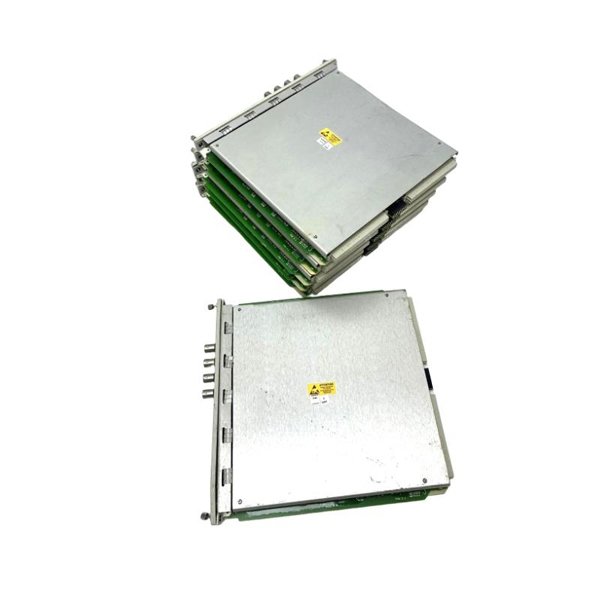

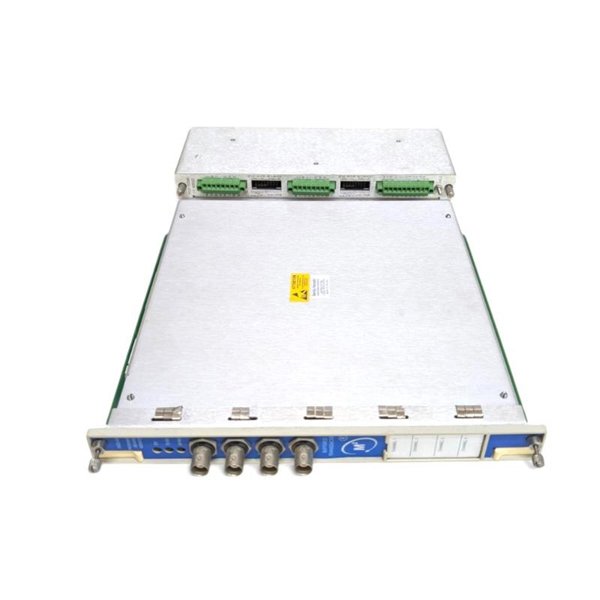

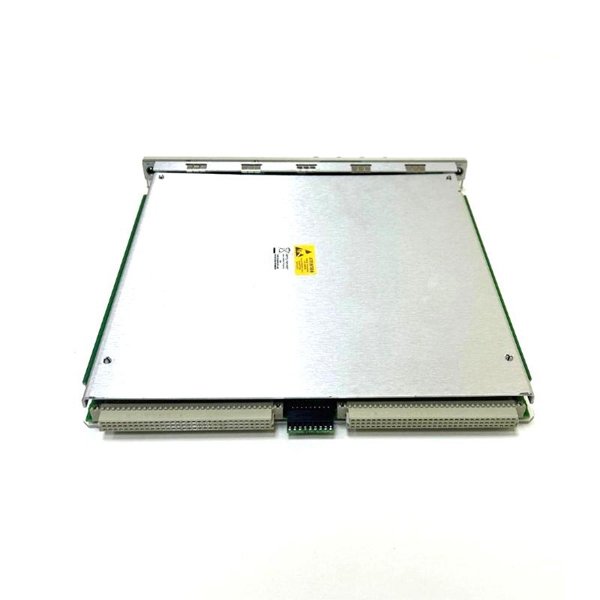

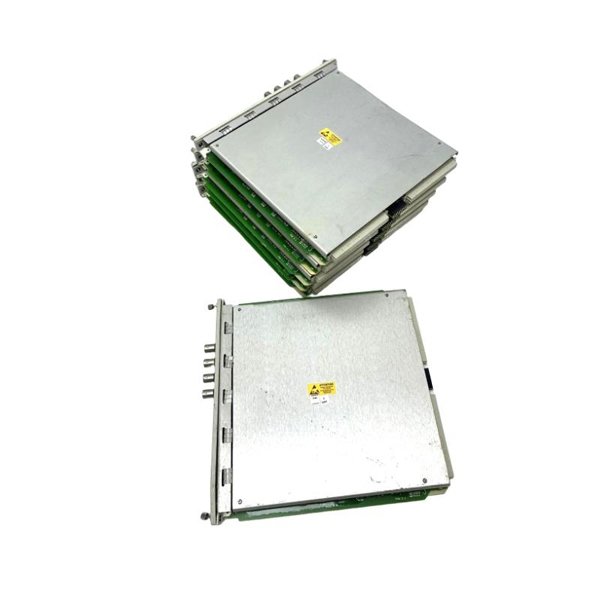

Bently Nevada 3500/42-02-00 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-02-00

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-02-00 Proximitor Seismic Monitor is an advanced dual-channel module designed for continuous monitoring of shaft vibration, position, and seismic measurements in critical rotating machinery. Engineered for integration into the 3500 Series Machinery Protection System, it offers high-accuracy measurement, configurable alarm setpoints, and real-time diagnostics to ensure machinery health and operational reliability.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/42-02-00 |

| Channels | 2 independent |

| Measurement Types | Proximity (shaft position/vibration), Seismic (velocity/acceleration) |

| Input Signal | Proximitor® sensor or seismic transducer |

| Frequency Response | Configurable per application |

| Alarm Setpoints | 2 per channel (Alert & Danger) |

| Outputs | 4-20 mA proportional to measured variable, buffered transducer signals |

| Communication | Via 3500 rack to System 1® software |

| Power Supply | From 3500 rack |

| Mounting | 3500 Series rack slot |

| Dimensions (H × W × D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | –30°C to +65°C |

| Certifications | CE, CSA, ATEX (varies with configuration) |

Applications

-

Turbomachinery Protection – Continuous monitoring of large steam and gas turbines.

-

Compressor Vibration Tracking – Detecting imbalance, misalignment, and surge conditions.

-

Generator and Motor Monitoring – Ensuring rotor stability and preventing bearing failures.

-

Seismic Motion Detection – Monitoring foundation and structural vibration for critical process equipment.

Advantages

-

High Accuracy – Precision measurement for early fault detection.

-

Flexible Configuration – Supports both proximitor and seismic sensors.

-

Integrated Protection – Direct interface with the 3500 rack for trip and shutdown logic.

-

Comprehensive Diagnostics – Enables condition-based maintenance via System 1® software.

-

Proven Reliability – Field-tested in harsh industrial environments.

FAQ

-

What is the primary function of the 3500/42-02-00?

It measures shaft vibration, position, or seismic motion for machinery protection.

-

Can it monitor two machines at once?

Yes, its two channels can be assigned to separate sensors or machines.

-

Which sensors are compatible?

Compatible with Bently Nevada Proximitor® sensors and seismic velocity or acceleration transducers.

-

Does it require external power?

No, it draws power from the 3500 rack.

-

How are alarms triggered?

Configurable Alert and Danger setpoints per channel trigger rack alarms and relay actions.

-

Is it suitable for hazardous areas?

Yes, with appropriate certified sensors and rack modules.

-

How is data accessed?

Through the 3500 rack outputs, buffered BNC connectors, and System 1® software.

-

What is the typical frequency range?

Configurable, depending on sensor type and application requirements.

-

Can it output a 4-20 mA signal?

Yes, each channel provides a proportional 4-20 mA output.

-

How is it installed?

It is inserted into a designated slot in the 3500 rack and configured via rack software.

Bently Nevada 3500/42-02-00 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-02-00

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-02-00 Proximitor Seismic Monitor is an advanced dual-channel module designed for continuous monitoring of shaft vibration, position, and seismic measurements in critical rotating machinery. Engineered for integration into the 3500 Series Machinery Protection System, it offers high-accuracy measurement, configurable alarm setpoints, and real-time diagnostics to ensure machinery health and operational reliability.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/42-02-00 |

| Channels | 2 independent |

| Measurement Types | Proximity (shaft position/vibration), Seismic (velocity/acceleration) |

| Input Signal | Proximitor® sensor or seismic transducer |

| Frequency Response | Configurable per application |

| Alarm Setpoints | 2 per channel (Alert & Danger) |

| Outputs | 4-20 mA proportional to measured variable, buffered transducer signals |

| Communication | Via 3500 rack to System 1® software |

| Power Supply | From 3500 rack |

| Mounting | 3500 Series rack slot |

| Dimensions (H × W × D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | –30°C to +65°C |

| Certifications | CE, CSA, ATEX (varies with configuration) |

Applications

-

Turbomachinery Protection – Continuous monitoring of large steam and gas turbines.

-

Compressor Vibration Tracking – Detecting imbalance, misalignment, and surge conditions.

-

Generator and Motor Monitoring – Ensuring rotor stability and preventing bearing failures.

-

Seismic Motion Detection – Monitoring foundation and structural vibration for critical process equipment.

Advantages

-

High Accuracy – Precision measurement for early fault detection.

-

Flexible Configuration – Supports both proximitor and seismic sensors.

-

Integrated Protection – Direct interface with the 3500 rack for trip and shutdown logic.

-

Comprehensive Diagnostics – Enables condition-based maintenance via System 1® software.

-

Proven Reliability – Field-tested in harsh industrial environments.

FAQ

-

What is the primary function of the 3500/42-02-00?

It measures shaft vibration, position, or seismic motion for machinery protection.

-

Can it monitor two machines at once?

Yes, its two channels can be assigned to separate sensors or machines.

-

Which sensors are compatible?

Compatible with Bently Nevada Proximitor® sensors and seismic velocity or acceleration transducers.

-

Does it require external power?

No, it draws power from the 3500 rack.

-

How are alarms triggered?

Configurable Alert and Danger setpoints per channel trigger rack alarms and relay actions.

-

Is it suitable for hazardous areas?

Yes, with appropriate certified sensors and rack modules.

-

How is data accessed?

Through the 3500 rack outputs, buffered BNC connectors, and System 1® software.

-

What is the typical frequency range?

Configurable, depending on sensor type and application requirements.

-

Can it output a 4-20 mA signal?

Yes, each channel provides a proportional 4-20 mA output.

-

How is it installed?

It is inserted into a designated slot in the 3500 rack and configured via rack software.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...