Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

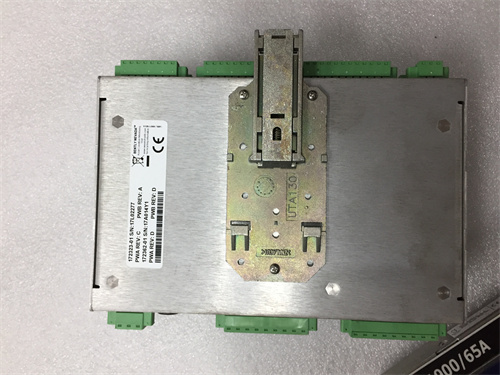

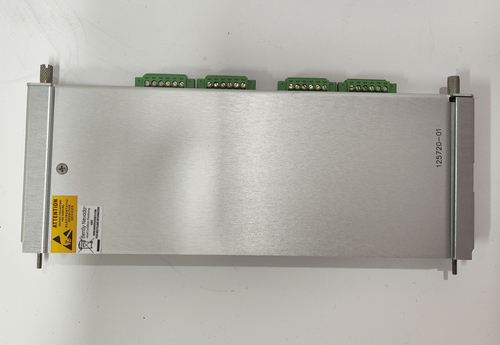

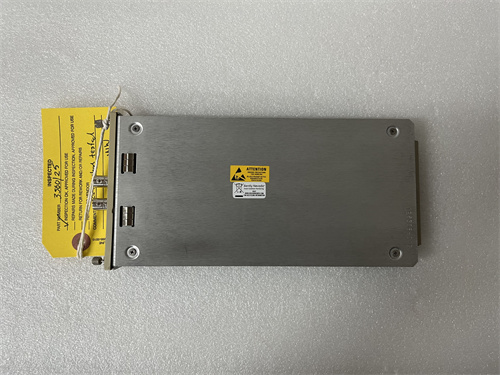

Bently Nevada 3500/22M 146031-02 100Base-FX Fiber Optic I/O Module

Manufacturer:Bently Nevada

Product Number:3500/22M 146031-02

Product Type:100Base-FX Fiber Optic I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 99.1 mm

Weight:0.2 kg

Views:30

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/22M 146031-02 100Base-FX Fiber Optic I/O Module is a high-performance communication interface module designed for use within the Bently Nevada 3500 Series machinery protection and condition monitoring system. This particular variant is equipped with a 100Base-FX fiber optic communication interface, enabling high-speed, noise-resistant data transfer between the 3500 rack and external monitoring or control systems.

By using fiber optic transmission, the 3500/22M 146031-02 ensures reliable, long-distance communication even in electrically noisy industrial environments. It plays a pivotal role in transmitting high-resolution transient vibration data—critical for early fault detection—especially in applications where electromagnetic interference (EMI) can compromise traditional copper-based links.

This module is ideal for demanding industrial environments such as power generation plants, offshore oil platforms, petrochemical facilities, and heavy manufacturing, where high-speed data integrity and equipment protection are paramount.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 3500/22M 146031-02 |

| Function | Transient Data Interface I/O with Fiber Optic |

| Communication Type | 100Base-FX (Fiber Optic, Multimode ST Connector) |

| Compatible System | Bently Nevada 3500 Series |

| Signal Type | Transient vibration data |

| Data Acquisition | High-speed event capture |

| Power Supply | 24 V DC |

| Power Consumption | Approx. 5 W |

| Dimensions (W x H x D) | 241.3 x 24.4 x 99.1 mm |

| Weight | 0.2 kg |

| Operating Temperature | -20 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | Up to 95%, non-condensing |

| Connectors | ST-style fiber optic connectors |

| Certifications | CE, UL, ATEX (if applicable) |

Product Applications

The 3500/22M 146031-02 module is widely deployed in high-noise or long-distance monitoring environments, supporting both machinery protection and advanced diagnostics:

-

Power Generation Plants

For monitoring turbines, boilers, and generators where EMI protection is crucial.

-

Oil & Gas Exploration and Refining

Used on offshore rigs, pipelines, and compressors to ensure data integrity over fiber links.

-

Petrochemical Processing

Enables fast, accurate diagnostics in corrosive and high-temperature environments.

-

Mining and Metallurgy

Ideal for vibration signal capture from conveyors, crushers, and mills in remote locations.

-

Marine and Naval Applications

Ensures vibration monitoring of shipboard equipment under harsh maritime conditions.

-

Industrial Automation and Robotics

Provides real-time, interference-free monitoring of fast-moving automated systems.

Product Advantages

-

Fiber Optic Communication

Immune to electrical noise, ideal for EMI-heavy environments and long-distance data transmission.

-

100Base-FX allows for rapid and accurate transmission of vibration data to monitoring systems.

-

Early Fault Detection

Captures transient mechanical events like rubbing, imbalance, and bearing wear at early stages.

-

Rugged Industrial Design

Built to endure harsh conditions including temperature extremes and high humidity.

-

System Compatibility

Fully compatible with the Bently Nevada 3500 Series rack and protection modules.

-

Energy Efficient

Low power consumption while providing high-speed, high-integrity data transfer.

-

Enhanced Safety

Certified for use in potentially hazardous environments (ATEX where applicable).

-

Space-Saving Format

Compact design for seamless integration into existing 3500 system racks.

-

Diagnostic Reliability

Ensures the delivery of clean, undistorted transient data critical for predictive maintenance.

-

Field Proven

Trusted across industries for dependable operation and long service life.

Frequently Asked Questions (FAQ)

-

What is the primary role of the 3500/22M 146031-02 module?

It transmits transient vibration data via fiber optics from the Bently Nevada 3500 system to external systems.

-

What type of fiber optic connection does this module use?

It uses 100Base-FX multimode ST-style fiber optic connectors for communication.

-

Why choose fiber optic over traditional copper interfaces?

Fiber is immune to EMI, supports longer distances, and offers greater data integrity in industrial environments.

-

What equipment can this module help monitor?

Turbines, compressors, motors, pumps, and other rotating machinery requiring high-speed diagnostics.

-

Is this module compatible with all 3500 racks?

Yes, it is fully compatible with all standard 3500 monitoring system racks.

-

How does it support predictive maintenance strategies?

It provides high-resolution data on transient events that are critical to diagnosing developing mechanical faults.

-

Can the fiber optic link be extended over long distances?

Yes, 100Base-FX supports longer distances than copper—typically up to 2 km with multimode fiber.

-

Is any special software required to use this module?

It integrates with Bently Nevada System 1 and other compatible vibration monitoring platforms.

-

What safety certifications does it meet?

It meets CE, UL, and optionally ATEX standards for use in hazardous environments.

-

Does this module require regular calibration or maintenance?

It is low-maintenance; routine inspection of fiber links and basic cleaning is typically sufficient.

Bently Nevada 3500/22M 146031-02 100Base-FX Fiber Optic I/O Module

Manufacturer:Bently Nevada

Product Number:3500/22M 146031-02

Product Type:100Base-FX Fiber Optic I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 99.1 mm

Weight:0.2 kg

Views:30

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/22M 146031-02 100Base-FX Fiber Optic I/O Module is a high-performance communication interface module designed for use within the Bently Nevada 3500 Series machinery protection and condition monitoring system. This particular variant is equipped with a 100Base-FX fiber optic communication interface, enabling high-speed, noise-resistant data transfer between the 3500 rack and external monitoring or control systems.

By using fiber optic transmission, the 3500/22M 146031-02 ensures reliable, long-distance communication even in electrically noisy industrial environments. It plays a pivotal role in transmitting high-resolution transient vibration data—critical for early fault detection—especially in applications where electromagnetic interference (EMI) can compromise traditional copper-based links.

This module is ideal for demanding industrial environments such as power generation plants, offshore oil platforms, petrochemical facilities, and heavy manufacturing, where high-speed data integrity and equipment protection are paramount.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 3500/22M 146031-02 |

| Function | Transient Data Interface I/O with Fiber Optic |

| Communication Type | 100Base-FX (Fiber Optic, Multimode ST Connector) |

| Compatible System | Bently Nevada 3500 Series |

| Signal Type | Transient vibration data |

| Data Acquisition | High-speed event capture |

| Power Supply | 24 V DC |

| Power Consumption | Approx. 5 W |

| Dimensions (W x H x D) | 241.3 x 24.4 x 99.1 mm |

| Weight | 0.2 kg |

| Operating Temperature | -20 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | Up to 95%, non-condensing |

| Connectors | ST-style fiber optic connectors |

| Certifications | CE, UL, ATEX (if applicable) |

Product Applications

The 3500/22M 146031-02 module is widely deployed in high-noise or long-distance monitoring environments, supporting both machinery protection and advanced diagnostics:

-

Power Generation Plants

For monitoring turbines, boilers, and generators where EMI protection is crucial.

-

Oil & Gas Exploration and Refining

Used on offshore rigs, pipelines, and compressors to ensure data integrity over fiber links.

-

Petrochemical Processing

Enables fast, accurate diagnostics in corrosive and high-temperature environments.

-

Mining and Metallurgy

Ideal for vibration signal capture from conveyors, crushers, and mills in remote locations.

-

Marine and Naval Applications

Ensures vibration monitoring of shipboard equipment under harsh maritime conditions.

-

Industrial Automation and Robotics

Provides real-time, interference-free monitoring of fast-moving automated systems.

Product Advantages

-

Fiber Optic Communication

Immune to electrical noise, ideal for EMI-heavy environments and long-distance data transmission.

-

100Base-FX allows for rapid and accurate transmission of vibration data to monitoring systems.

-

Early Fault Detection

Captures transient mechanical events like rubbing, imbalance, and bearing wear at early stages.

-

Rugged Industrial Design

Built to endure harsh conditions including temperature extremes and high humidity.

-

System Compatibility

Fully compatible with the Bently Nevada 3500 Series rack and protection modules.

-

Energy Efficient

Low power consumption while providing high-speed, high-integrity data transfer.

-

Enhanced Safety

Certified for use in potentially hazardous environments (ATEX where applicable).

-

Space-Saving Format

Compact design for seamless integration into existing 3500 system racks.

-

Diagnostic Reliability

Ensures the delivery of clean, undistorted transient data critical for predictive maintenance.

-

Field Proven

Trusted across industries for dependable operation and long service life.

Frequently Asked Questions (FAQ)

-

What is the primary role of the 3500/22M 146031-02 module?

It transmits transient vibration data via fiber optics from the Bently Nevada 3500 system to external systems.

-

What type of fiber optic connection does this module use?

It uses 100Base-FX multimode ST-style fiber optic connectors for communication.

-

Why choose fiber optic over traditional copper interfaces?

Fiber is immune to EMI, supports longer distances, and offers greater data integrity in industrial environments.

-

What equipment can this module help monitor?

Turbines, compressors, motors, pumps, and other rotating machinery requiring high-speed diagnostics.

-

Is this module compatible with all 3500 racks?

Yes, it is fully compatible with all standard 3500 monitoring system racks.

-

How does it support predictive maintenance strategies?

It provides high-resolution data on transient events that are critical to diagnosing developing mechanical faults.

-

Can the fiber optic link be extended over long distances?

Yes, 100Base-FX supports longer distances than copper—typically up to 2 km with multimode fiber.

-

Is any special software required to use this module?

It integrates with Bently Nevada System 1 and other compatible vibration monitoring platforms.

-

What safety certifications does it meet?

It meets CE, UL, and optionally ATEX standards for use in hazardous environments.

-

Does this module require regular calibration or maintenance?

It is low-maintenance; routine inspection of fiber links and basic cleaning is typically sufficient.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...