Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

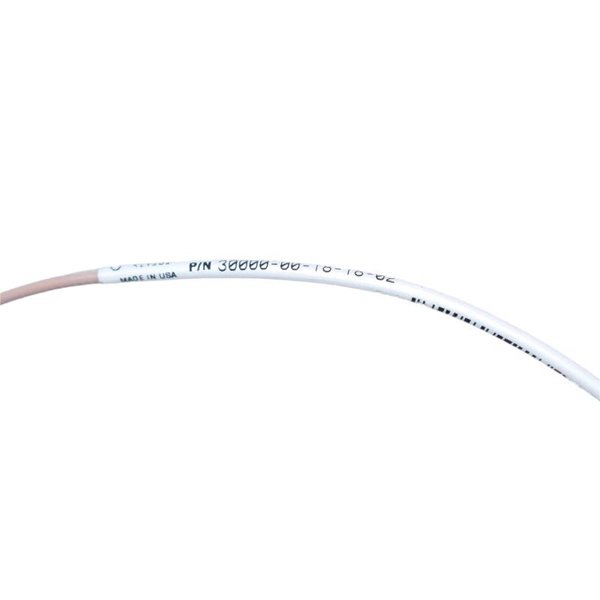

Bently Nevada 30000-00-08-18-02 Probe Vibration Sensor

Manufacturer:Bently Nevada

Product Number:30000-00-08-18-02

Product Type:Probe Vibration Sensor

Origin:USA

Cable Length:Optional

Shipping Weight:3 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 30000-00-08-18-02 Probe Vibration Sensor is an industrial-grade sensor designed to provide high-precision vibration and displacement monitoring for rotating machinery. It is used to detect subtle shaft movements, imbalance, misalignment, rubbing, and other mechanical faults that could compromise machinery reliability.

This sensor employs advanced eddy-current proximity technology, ensuring highly accurate and repeatable measurements under demanding conditions, including high vibration, temperature variation, and rotational speed fluctuations. Its robust design makes it ideal for turbines, compressors, generators, pumps, and other critical rotating equipment. The optional cable length feature allows for flexible installation according to specific operational requirements.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 30000-00-08-18-02 |

| Sensor Type | Probe Vibration Sensor |

| Series | 30000 |

| Tip Material | Hardened Stainless Steel |

| Cable Length | Optional |

| Measuring Range | ±0.254 mm (±10 mils) |

| Linearity | ±1% of full scale |

| Frequency Response | DC to 10 kHz |

| Operating Temperature | -40°C to 120°C |

| Mounting Type | Standard threaded or flanged mount |

| Housing Material | Stainless Steel |

| Shipping Weight | 3 kg |

| Environmental Rating | IP67 |

Applications

-

Turbines: Monitors shaft vibration to detect rotor-stator contact.

-

Compressors: Detects misalignment, imbalance, and abnormal shaft motion.

-

Generators: Ensures smooth operation by tracking vibration.

-

Industrial Pumps: Detects mechanical faults early to prevent downtime.

-

Condition Monitoring Systems: Provides critical data for predictive maintenance.

-

Rotating Machinery Protection: Enables early detection of rubbing, looseness, or shaft deflection.

This sensor allows operators to make informed maintenance decisions, minimize downtime, and maintain machinery reliability.

Advantages

-

High Precision: Eddy-current technology delivers accurate and repeatable measurements.

-

Rugged Design: Stainless steel housing and hardened tip withstand harsh industrial environments.

-

Wide Frequency Response: DC to 10 kHz allows capturing both slow and rapid vibrations.

-

Flexible Installation: Optional cable length provides adaptability for different machinery layouts.

-

Reliable Performance: Maintains stability under high vibration and temperature fluctuations.

-

Standard Mount Compatibility: Integrates seamlessly with Bently Nevada 3000 and 3500 series systems.

-

Low Maintenance: Solid-state design reduces servicing requirements.

-

Environmental Protection: IP67 rating ensures resistance to dust and water ingress.

Frequently Asked Questions (FAQ)

-

What is the measuring range of the 30000-00-08-18-02 sensor?

±0.254 mm (±10 mils) for precise shaft vibration detection.

-

What sensing technology does it use?

Eddy-current proximity sensing for high-resolution displacement measurements.

-

Can it operate in high-vibration industrial environments?

Yes, it is designed for stable performance under high vibration.

-

Is the sensor compatible with Bently Nevada 3000 and 3500 series systems?

Yes, full integration is supported.

-

What mounting methods are recommended?

Standard threaded or flanged mounting ensures secure installation.

-

What materials are used for the probe tip and housing?

Hardened stainless steel tip and stainless steel housing for durability and wear resistance.

-

What is the frequency response of the sensor?

DC to 10 kHz, allowing monitoring of both low and high-frequency vibrations.

-

Is the cable length customizable?

Yes, cable length is optional to accommodate different installation needs.

-

Does the sensor require calibration?

Periodic calibration is recommended to maintain accuracy.

-

What environmental conditions can it withstand?

IP67 rating ensures protection from dust and water ingress, suitable for harsh industrial conditions.

Bently Nevada 30000-00-08-18-02 Probe Vibration Sensor

Manufacturer:Bently Nevada

Product Number:30000-00-08-18-02

Product Type:Probe Vibration Sensor

Origin:USA

Cable Length:Optional

Shipping Weight:3 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 30000-00-08-18-02 Probe Vibration Sensor is an industrial-grade sensor designed to provide high-precision vibration and displacement monitoring for rotating machinery. It is used to detect subtle shaft movements, imbalance, misalignment, rubbing, and other mechanical faults that could compromise machinery reliability.

This sensor employs advanced eddy-current proximity technology, ensuring highly accurate and repeatable measurements under demanding conditions, including high vibration, temperature variation, and rotational speed fluctuations. Its robust design makes it ideal for turbines, compressors, generators, pumps, and other critical rotating equipment. The optional cable length feature allows for flexible installation according to specific operational requirements.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 30000-00-08-18-02 |

| Sensor Type | Probe Vibration Sensor |

| Series | 30000 |

| Tip Material | Hardened Stainless Steel |

| Cable Length | Optional |

| Measuring Range | ±0.254 mm (±10 mils) |

| Linearity | ±1% of full scale |

| Frequency Response | DC to 10 kHz |

| Operating Temperature | -40°C to 120°C |

| Mounting Type | Standard threaded or flanged mount |

| Housing Material | Stainless Steel |

| Shipping Weight | 3 kg |

| Environmental Rating | IP67 |

Applications

-

Turbines: Monitors shaft vibration to detect rotor-stator contact.

-

Compressors: Detects misalignment, imbalance, and abnormal shaft motion.

-

Generators: Ensures smooth operation by tracking vibration.

-

Industrial Pumps: Detects mechanical faults early to prevent downtime.

-

Condition Monitoring Systems: Provides critical data for predictive maintenance.

-

Rotating Machinery Protection: Enables early detection of rubbing, looseness, or shaft deflection.

This sensor allows operators to make informed maintenance decisions, minimize downtime, and maintain machinery reliability.

Advantages

-

High Precision: Eddy-current technology delivers accurate and repeatable measurements.

-

Rugged Design: Stainless steel housing and hardened tip withstand harsh industrial environments.

-

Wide Frequency Response: DC to 10 kHz allows capturing both slow and rapid vibrations.

-

Flexible Installation: Optional cable length provides adaptability for different machinery layouts.

-

Reliable Performance: Maintains stability under high vibration and temperature fluctuations.

-

Standard Mount Compatibility: Integrates seamlessly with Bently Nevada 3000 and 3500 series systems.

-

Low Maintenance: Solid-state design reduces servicing requirements.

-

Environmental Protection: IP67 rating ensures resistance to dust and water ingress.

Frequently Asked Questions (FAQ)

-

What is the measuring range of the 30000-00-08-18-02 sensor?

±0.254 mm (±10 mils) for precise shaft vibration detection.

-

What sensing technology does it use?

Eddy-current proximity sensing for high-resolution displacement measurements.

-

Can it operate in high-vibration industrial environments?

Yes, it is designed for stable performance under high vibration.

-

Is the sensor compatible with Bently Nevada 3000 and 3500 series systems?

Yes, full integration is supported.

-

What mounting methods are recommended?

Standard threaded or flanged mounting ensures secure installation.

-

What materials are used for the probe tip and housing?

Hardened stainless steel tip and stainless steel housing for durability and wear resistance.

-

What is the frequency response of the sensor?

DC to 10 kHz, allowing monitoring of both low and high-frequency vibrations.

-

Is the cable length customizable?

Yes, cable length is optional to accommodate different installation needs.

-

Does the sensor require calibration?

Periodic calibration is recommended to maintain accuracy.

-

What environmental conditions can it withstand?

IP67 rating ensures protection from dust and water ingress, suitable for harsh industrial conditions.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...