Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

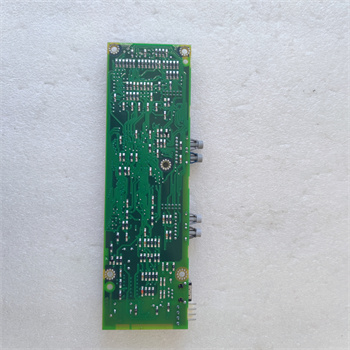

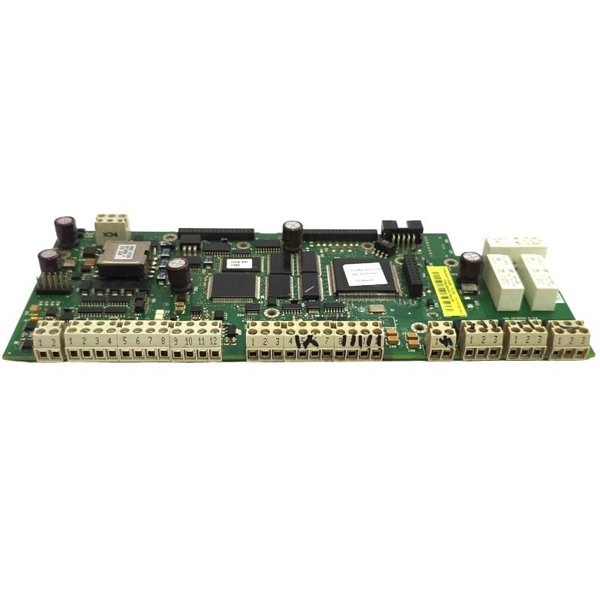

ABB RMIO-11C 3AUA0000035408 Control Board

Manufacturer:ABB

Product Number:RMIO-11C 3AUA0000035408

Product Type:Control Board

Origin:Sweden (SE)

Dimensions:50 x 120 x 290 mm

Weight:0.25 kg

Views:83

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

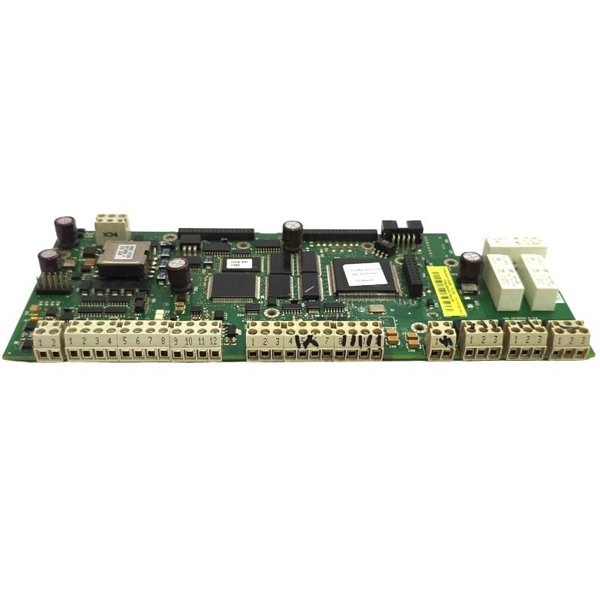

The ABB RMIO-11C (3AUA0000035408) Control Board is an advanced electronic module designed for relay, monitoring, and automation applications within ABB low- and medium-voltage systems. It functions as the primary control interface in protection relays, motor protection systems, and distribution control units, enabling accurate signal processing, monitoring, and control of electrical equipment.

The RMIO-11C is built with high-quality industrial components to ensure stable operation, precise control, and reliable communication in demanding environments. Its compact design allows easy integration into relay panels and motor control centers, supporting both standalone and networked configurations. With onboard diagnostics, configurable inputs and outputs, and support for multiple communication protocols, the RMIO-11C enhances system safety, flexibility, and maintainability.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | ABB RMIO-11C / 3AUA0000035408 |

| Type | Control Board / Monitoring Interface |

| Function | Relay and automation control for protection systems |

| Processor | 32-bit industrial microcontroller |

| I/O Interfaces | 8 digital inputs, 4 digital outputs, 2 analog inputs |

| Communication | RS-485, Modbus RTU, CAN |

| Input Voltage | 24 V DC nominal |

| Power Consumption | ≤ 10 W |

| Operating Temperature | -20 to 60 °C |

| Storage Temperature | -40 to 70 °C |

| Humidity | 10–95% RH, non-condensing |

| Mounting | DIN rail or panel mount |

| Dimensions (W x H x D) | 50 x 120 x 290 mm |

| Weight | 0.25 kg |

| Compliance | IEC 61131, CE, UL recognized |

Product Applications

The RMIO-11C control board is widely used in industrial and utility applications where monitoring, control, and automation are critical:

-

Motor Protection – Integrates with motor protection relays to monitor status, alarms, and fault conditions.

-

Power Distribution – Controls auxiliary functions and signaling in switchgear and distribution panels.

-

Industrial Automation – Interfaces with PLCs and remote I/O systems in manufacturing plants.

-

Renewable Energy Systems – Provides monitoring and control for wind turbines and solar converters.

-

Oil & Gas Industry – Used in pump stations, pipelines, and process control panels.

-

Water & Wastewater Treatment – Enables automated monitoring and control of pumps and valves.

Product Advantages

-

Reliable Performance – Industrial-grade components provide stable operation under harsh conditions.

-

Flexible I/O – Supports multiple digital and analog inputs and outputs for diverse applications.

-

Communication Ready – Compatible with RS-485, Modbus RTU, and CAN networks.

-

Compact & Modular – Easy integration into panels, relay racks, and motor control centers.

-

Enhanced Diagnostics – Built-in status indicators and diagnostic routines improve maintainability.

-

Energy Efficient – Low power consumption reduces heat and energy requirements.

-

Standards Compliant – Meets IEC, CE, and UL standards for electrical and functional safety.

FAQ

-

What is the primary function of the RMIO-11C control board?

The RMIO-11C acts as the central interface for relay, monitoring, and automation applications, processing input signals, controlling outputs, and providing communication between motor protection devices, relays, and supervisory control systems.

-

Which communication protocols are available on the board?

This board supports RS-485, Modbus RTU, and CAN, enabling integration with ABB relay systems, PLCs, and remote I/O networks for real-time control and monitoring.

-

How many digital inputs and outputs does the RMIO-11C provide?

It includes 8 digital inputs for monitoring external signals and 4 digital outputs to drive relays or signaling devices, allowing versatile interfacing with industrial equipment.

-

Does the board support analog input signals?

Yes, it has 2 analog input channels suitable for monitoring process variables such as voltage, current, or sensor outputs in industrial automation and motor protection systems.

-

Can the RMIO-11C be mounted on standard DIN rails?

Yes, the board is designed for both DIN rail and panel mounting, allowing flexible installation in relay cabinets, motor control centers, or distribution panels.

-

What is the required operating voltage for this control board?

The board operates on a 24 V DC nominal supply, which is standard for industrial control systems, ensuring stable and efficient operation of its electronics.

-

Is the RMIO-11C suitable for motor protection applications?

Yes, it integrates with ABB motor protection relays to monitor status, detect faults, and control auxiliary functions, enhancing protection and operational reliability.

-

Can the control board operate in high-humidity or industrial environments?

Yes, it is rated for 10–95% relative humidity (non-condensing) and can withstand typical industrial conditions such as temperature variations, dust, and electrical noise.

-

Does the board provide diagnostics or status feedback?

Yes, the RMIO-11C features onboard LEDs and self-diagnostic routines that allow real-time monitoring of its operational status, communication integrity, and I/O activity.

-

Is the RMIO-11C compatible with legacy ABB control systems?

Yes, it is designed to integrate seamlessly with both modern and older ABB relay panels and control systems, ensuring backward compatibility and easy retrofitting.

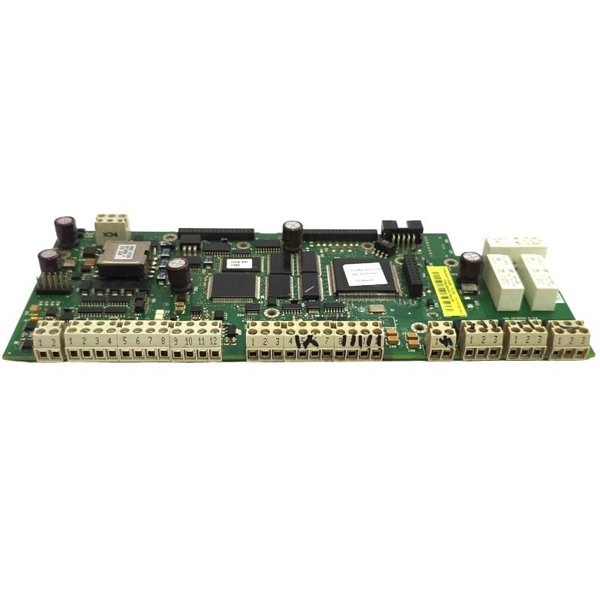

ABB RMIO-11C 3AUA0000035408 Control Board

Manufacturer:ABB

Product Number:RMIO-11C 3AUA0000035408

Product Type:Control Board

Origin:Sweden (SE)

Dimensions:50 x 120 x 290 mm

Weight:0.25 kg

Views:83

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB RMIO-11C (3AUA0000035408) Control Board is an advanced electronic module designed for relay, monitoring, and automation applications within ABB low- and medium-voltage systems. It functions as the primary control interface in protection relays, motor protection systems, and distribution control units, enabling accurate signal processing, monitoring, and control of electrical equipment.

The RMIO-11C is built with high-quality industrial components to ensure stable operation, precise control, and reliable communication in demanding environments. Its compact design allows easy integration into relay panels and motor control centers, supporting both standalone and networked configurations. With onboard diagnostics, configurable inputs and outputs, and support for multiple communication protocols, the RMIO-11C enhances system safety, flexibility, and maintainability.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | ABB RMIO-11C / 3AUA0000035408 |

| Type | Control Board / Monitoring Interface |

| Function | Relay and automation control for protection systems |

| Processor | 32-bit industrial microcontroller |

| I/O Interfaces | 8 digital inputs, 4 digital outputs, 2 analog inputs |

| Communication | RS-485, Modbus RTU, CAN |

| Input Voltage | 24 V DC nominal |

| Power Consumption | ≤ 10 W |

| Operating Temperature | -20 to 60 °C |

| Storage Temperature | -40 to 70 °C |

| Humidity | 10–95% RH, non-condensing |

| Mounting | DIN rail or panel mount |

| Dimensions (W x H x D) | 50 x 120 x 290 mm |

| Weight | 0.25 kg |

| Compliance | IEC 61131, CE, UL recognized |

Product Applications

The RMIO-11C control board is widely used in industrial and utility applications where monitoring, control, and automation are critical:

-

Motor Protection – Integrates with motor protection relays to monitor status, alarms, and fault conditions.

-

Power Distribution – Controls auxiliary functions and signaling in switchgear and distribution panels.

-

Industrial Automation – Interfaces with PLCs and remote I/O systems in manufacturing plants.

-

Renewable Energy Systems – Provides monitoring and control for wind turbines and solar converters.

-

Oil & Gas Industry – Used in pump stations, pipelines, and process control panels.

-

Water & Wastewater Treatment – Enables automated monitoring and control of pumps and valves.

Product Advantages

-

Reliable Performance – Industrial-grade components provide stable operation under harsh conditions.

-

Flexible I/O – Supports multiple digital and analog inputs and outputs for diverse applications.

-

Communication Ready – Compatible with RS-485, Modbus RTU, and CAN networks.

-

Compact & Modular – Easy integration into panels, relay racks, and motor control centers.

-

Enhanced Diagnostics – Built-in status indicators and diagnostic routines improve maintainability.

-

Energy Efficient – Low power consumption reduces heat and energy requirements.

-

Standards Compliant – Meets IEC, CE, and UL standards for electrical and functional safety.

FAQ

-

What is the primary function of the RMIO-11C control board?

The RMIO-11C acts as the central interface for relay, monitoring, and automation applications, processing input signals, controlling outputs, and providing communication between motor protection devices, relays, and supervisory control systems.

-

Which communication protocols are available on the board?

This board supports RS-485, Modbus RTU, and CAN, enabling integration with ABB relay systems, PLCs, and remote I/O networks for real-time control and monitoring.

-

How many digital inputs and outputs does the RMIO-11C provide?

It includes 8 digital inputs for monitoring external signals and 4 digital outputs to drive relays or signaling devices, allowing versatile interfacing with industrial equipment.

-

Does the board support analog input signals?

Yes, it has 2 analog input channels suitable for monitoring process variables such as voltage, current, or sensor outputs in industrial automation and motor protection systems.

-

Can the RMIO-11C be mounted on standard DIN rails?

Yes, the board is designed for both DIN rail and panel mounting, allowing flexible installation in relay cabinets, motor control centers, or distribution panels.

-

What is the required operating voltage for this control board?

The board operates on a 24 V DC nominal supply, which is standard for industrial control systems, ensuring stable and efficient operation of its electronics.

-

Is the RMIO-11C suitable for motor protection applications?

Yes, it integrates with ABB motor protection relays to monitor status, detect faults, and control auxiliary functions, enhancing protection and operational reliability.

-

Can the control board operate in high-humidity or industrial environments?

Yes, it is rated for 10–95% relative humidity (non-condensing) and can withstand typical industrial conditions such as temperature variations, dust, and electrical noise.

-

Does the board provide diagnostics or status feedback?

Yes, the RMIO-11C features onboard LEDs and self-diagnostic routines that allow real-time monitoring of its operational status, communication integrity, and I/O activity.

-

Is the RMIO-11C compatible with legacy ABB control systems?

Yes, it is designed to integrate seamlessly with both modern and older ABB relay panels and control systems, ensuring backward compatibility and easy retrofitting.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...