Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

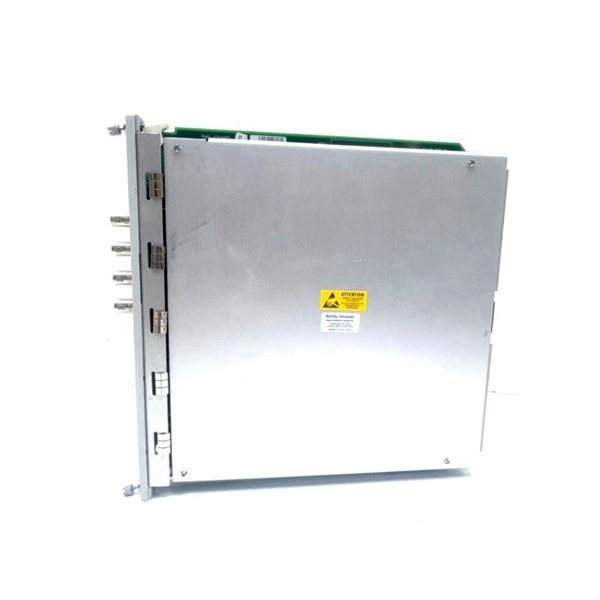

Bently Nevada 3500/42-01-CN Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-01-CN

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:28

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-01-CN Proximitor Seismic Monitor is a high-precision vibration monitoring module designed to measure absolute shaft vibration and seismic activity on rotating machinery. It ensures optimal machine protection and performance by providing continuous monitoring, configurable alarms, and integration into the Bently Nevada 3500 Series system.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/42-01-CN |

| Measurement Type | Proximitor / Seismic |

| Channels | 2 independent channels |

| Power Supply | Supplied via 3500 rack |

| Input Signal | Compatible with Proximitor® sensors or seismic transducers |

| Alarm Setpoints | 2 levels per channel (Alert / Danger) |

| Accuracy | ±0.1% of full scale |

| Frequency Response | 4 Hz to 5 kHz (depending on sensor type) |

| Operating Temperature | -30 °C to +65 °C |

| Humidity | 95% non-condensing |

| Dimensions | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 rack slot |

| Communication | Via 3500 rack backplane |

| Certifications | CE, CSA, ATEX (varies by configuration) |

Applications

-

Turbomachinery: Gas turbines, steam turbines, and compressors.

-

Industrial Rotating Equipment: Pumps, motors, fans, and gearboxes.

-

Seismic Monitoring: Detection of casing or bearing housing vibrations.

-

Condition Monitoring Systems: Integration into predictive maintenance programs.

-

Oil & Gas, Power Generation, Petrochemical Plants: Critical asset protection.

Advantages

-

High Reliability: Proven Bently Nevada 3500 platform with robust industrial design.

-

Dual Functionality: Supports both proximitor and seismic measurements.

-

Configurable Alarms: Two independent alarm levels per channel for prompt response.

-

Seamless Integration: Fully compatible with 3500 rack and system software.

-

Enhanced Safety: Early detection of vibration issues prevents catastrophic failures.

-

Low Maintenance: Solid-state design with long service life.

FAQ

-

Q: Can the 3500/42-01-CN monitor both shaft and casing vibration simultaneously?

A: Yes, it supports proximitor and seismic transducers on separate channels.

-

Q: What is the minimum frequency it can measure?

A: As low as 4 Hz, depending on the connected sensor.

-

Q: Is it suitable for hazardous environments?

A: Yes, certain configurations are ATEX and CSA certified.

-

Q: How is power supplied to the module?

A: Through the 3500 rack backplane—no separate power supply required.

-

Q: Can alarm setpoints be customized?

A: Yes, both Alert and Danger setpoints are user-configurable.

-

Q: Does it require regular calibration?

A: Calibration is recommended during major maintenance or per industry standards.

-

Q: Is real-time monitoring supported?

A: Yes, it provides continuous online monitoring.

-

Q: What is the maximum operating temperature?

A: +65 °C.

-

Q: How many channels does it have?

A: Two fully independent channels.

-

Q: Is it backward-compatible with older 3500 racks?

A: Yes, it is designed to be compatible with the standard 3500 rack architecture.

Bently Nevada 3500/42-01-CN Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-01-CN

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:28

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-01-CN Proximitor Seismic Monitor is a high-precision vibration monitoring module designed to measure absolute shaft vibration and seismic activity on rotating machinery. It ensures optimal machine protection and performance by providing continuous monitoring, configurable alarms, and integration into the Bently Nevada 3500 Series system.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/42-01-CN |

| Measurement Type | Proximitor / Seismic |

| Channels | 2 independent channels |

| Power Supply | Supplied via 3500 rack |

| Input Signal | Compatible with Proximitor® sensors or seismic transducers |

| Alarm Setpoints | 2 levels per channel (Alert / Danger) |

| Accuracy | ±0.1% of full scale |

| Frequency Response | 4 Hz to 5 kHz (depending on sensor type) |

| Operating Temperature | -30 °C to +65 °C |

| Humidity | 95% non-condensing |

| Dimensions | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 rack slot |

| Communication | Via 3500 rack backplane |

| Certifications | CE, CSA, ATEX (varies by configuration) |

Applications

-

Turbomachinery: Gas turbines, steam turbines, and compressors.

-

Industrial Rotating Equipment: Pumps, motors, fans, and gearboxes.

-

Seismic Monitoring: Detection of casing or bearing housing vibrations.

-

Condition Monitoring Systems: Integration into predictive maintenance programs.

-

Oil & Gas, Power Generation, Petrochemical Plants: Critical asset protection.

Advantages

-

High Reliability: Proven Bently Nevada 3500 platform with robust industrial design.

-

Dual Functionality: Supports both proximitor and seismic measurements.

-

Configurable Alarms: Two independent alarm levels per channel for prompt response.

-

Seamless Integration: Fully compatible with 3500 rack and system software.

-

Enhanced Safety: Early detection of vibration issues prevents catastrophic failures.

-

Low Maintenance: Solid-state design with long service life.

FAQ

-

Q: Can the 3500/42-01-CN monitor both shaft and casing vibration simultaneously?

A: Yes, it supports proximitor and seismic transducers on separate channels.

-

Q: What is the minimum frequency it can measure?

A: As low as 4 Hz, depending on the connected sensor.

-

Q: Is it suitable for hazardous environments?

A: Yes, certain configurations are ATEX and CSA certified.

-

Q: How is power supplied to the module?

A: Through the 3500 rack backplane—no separate power supply required.

-

Q: Can alarm setpoints be customized?

A: Yes, both Alert and Danger setpoints are user-configurable.

-

Q: Does it require regular calibration?

A: Calibration is recommended during major maintenance or per industry standards.

-

Q: Is real-time monitoring supported?

A: Yes, it provides continuous online monitoring.

-

Q: What is the maximum operating temperature?

A: +65 °C.

-

Q: How many channels does it have?

A: Two fully independent channels.

-

Q: Is it backward-compatible with older 3500 racks?

A: Yes, it is designed to be compatible with the standard 3500 rack architecture.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...