Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

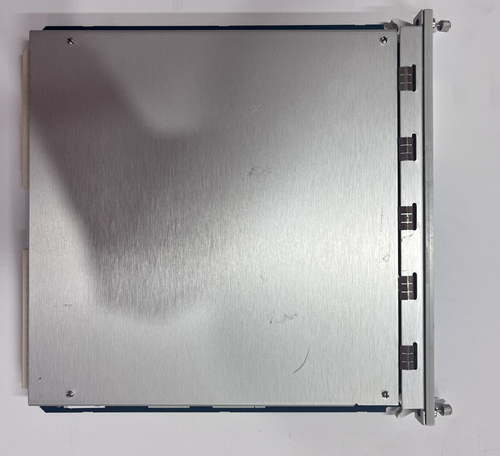

Bently Nevada 3500/23E Transient Data Interface (TDI) Module

Manufacturer:Bently Nevada

Product Number:3500/23E

Product Type:Transient Data Interface (TDI) Module

Origin:USA

Dimensions:228 x 50 x 289mm

Weight:1.45kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/23E Transient Data Interface (TDI) Module is a sophisticated industrial monitoring system designed to capture and analyze transient signals from rotating machinery, such as vibrations, pressure changes, and temperature fluctuations. As part of the Bently Nevada 3500 series, the 3500/23E module is engineered for high-performance data acquisition and reliable machinery health monitoring. It enables predictive maintenance by detecting early signs of wear, misalignment, or other operational issues in critical equipment before they lead to costly failures.

This module is widely used in industries such as power generation, oil and gas, mining, and manufacturing, where the performance and reliability of machinery are critical to operational efficiency. The 3500/23E is built to operate in challenging environments, offering robust protection and a high level of data accuracy.

By integrating the 3500/23E module with existing control systems, operators gain real-time visibility into the condition of their machinery, allowing them to take preventive measures that enhance safety and reduce unplanned downtime.

Product Specifications

| Specification | Details |

|---|---|

| Dimensions (L x W x H) | 228 x 50 x 289 mm |

| Weight | 1.45 kg |

| Input Voltage | 24V DC ± 10% |

| Operating Temperature Range | -40°C to +85°C |

| Input Channels | 8 differential or 16 single-ended |

| Communication Protocols | Modbus, Ethernet, RS-485 |

| Data Sampling Rate | 100 kHz |

| Accuracy | ±0.1% |

| Protection | IP20 rated |

| Mounting | DIN rail mounting |

Product Applications

The 3500/23E TDI Module is designed for high-speed data acquisition and precise signal monitoring in critical industrial applications. Below are some key applications where this module is most commonly used:

-

Power Generation

In power plants, turbines, compressors, and other key machinery require constant monitoring. The 3500/23E module captures transient data that helps identify early warning signs of faults, enabling power generation facilities to take proactive actions before major issues occur.

-

Oil and Gas

The 3500/23E module is crucial for monitoring equipment such as pumps, compressors, and drilling rigs in the oil and gas sector. It captures transient signals, which help detect mechanical failures or operational inefficiencies early, improving safety and reducing the likelihood of costly shutdowns.

-

Mining and Heavy Industry

The module is used in mining and heavy industrial settings to monitor large machines like crushers, mills, and conveyors. The ability to capture transient data enables operators to prevent costly breakdowns and extend the life of expensive equipment.

-

Automotive Manufacturing

In automotive manufacturing, the 3500/23E helps monitor machinery on production lines to ensure high precision and operational efficiency. The module detects early signs of failure, which helps avoid production delays and downtime.

-

Aerospace

Aerospace manufacturers rely on the 3500/23E module to monitor critical systems such as turbines and engines. The module ensures that any signs of wear or potential issues are detected early, contributing to the reliability and safety of aerospace operations.

Product Advantages

-

High-Speed Data Acquisition

The 3500/23E module offers a data sampling rate of 100 kHz, enabling it to capture transient signals in real time with exceptional accuracy. This capability helps operators identify minor mechanical issues before they escalate into larger, more expensive problems.

-

Wide Temperature Range

The module operates in a temperature range of -40°C to +85°C, ensuring its functionality in a wide variety of industrial environments, from extreme cold to high-heat settings.

-

Compact and Lightweight Design

With dimensions of 228 x 50 x 289 mm and a weight of only 1.45 kg, the 3500/23E module is compact and lightweight, making it easy to install and integrate into existing systems, even in space-constrained areas.

-

Flexibility in Input Channels

The 3500/23E module can handle up to 8 differential or 16 single-ended input channels, offering versatility in monitoring a wide array of equipment.

-

Reliable Protection

The module is IP20 rated, providing protection from dust and other environmental factors. This ensures that it operates reliably even in challenging industrial conditions.

-

Seamless Integration

Supporting Modbus, Ethernet, and RS-485 communication protocols, the 3500/23E integrates easily into existing control systems, providing a seamless monitoring solution.

-

Predictive Maintenance

By capturing transient data, the module plays a crucial role in predictive maintenance strategies. This allows operators to detect issues early, thus reducing unplanned downtime and costly repairs.

-

Durability and Longevity

Built to withstand harsh environments, the 3500/23E module is designed for long-term performance, minimizing the need for maintenance and ensuring reliability over time.

FAQ

Q1: What is the purpose of the Bently Nevada 3500/23E module?

A1: The 3500/23E module is used to capture transient signals such as vibrations, pressure fluctuations, and temperature changes, helping to monitor and maintain the health of industrial machinery.

Q2: How many input channels does the 3500/23E module support?

A2: The 3500/23E module supports up to 8 differential or 16 single-ended input channels, providing flexibility in monitoring various machines or sensors.

Q3: What is the data sampling rate of this module?

A3: The module offers a high-speed data sampling rate of 100 kHz, ensuring real-time capture and analysis of transient data.

Q4: Can this module operate in extreme temperatures?

A4: Yes, the 3500/23E module operates in a wide temperature range of -40°C to +85°C, making it suitable for use in both hot and cold environments.

Q5: What are the communication protocols supported by the 3500/23E?

A5: The module supports Modbus, Ethernet, and RS-485 communication protocols, allowing seamless integration with various industrial control systems.

Q6: How is the 3500/23E module mounted?

A6: The 3500/23E module is designed for DIN rail mounting, making it easy to install in control panels and other industrial systems.

Q7: What kind of protection does the module provide?

A7: The 3500/23E is rated IP20, which offers protection against dust and other environmental contaminants, ensuring reliable performance in industrial settings.

Q8: What industries benefit from using the 3500/23E?

A8: The 3500/23E module is used in industries such as power generation, oil and gas, mining, automotive manufacturing, and aerospace to monitor critical machinery.

Q9: How much does the module weigh?

A9: The 3500/23E module weighs 1.45 kg, making it lightweight and easy to handle during installation and maintenance.

Q10: Is the 3500/23E module compatible with other Bently Nevada products?

A10: Yes, the 3500/23E module is fully compatible with other Bently Nevada monitoring systems, allowing for a complete and integrated machinery monitoring solution.

Bently Nevada 3500/23E Transient Data Interface (TDI) Module

Manufacturer:Bently Nevada

Product Number:3500/23E

Product Type:Transient Data Interface (TDI) Module

Origin:USA

Dimensions:228 x 50 x 289mm

Weight:1.45kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/23E Transient Data Interface (TDI) Module is a sophisticated industrial monitoring system designed to capture and analyze transient signals from rotating machinery, such as vibrations, pressure changes, and temperature fluctuations. As part of the Bently Nevada 3500 series, the 3500/23E module is engineered for high-performance data acquisition and reliable machinery health monitoring. It enables predictive maintenance by detecting early signs of wear, misalignment, or other operational issues in critical equipment before they lead to costly failures.

This module is widely used in industries such as power generation, oil and gas, mining, and manufacturing, where the performance and reliability of machinery are critical to operational efficiency. The 3500/23E is built to operate in challenging environments, offering robust protection and a high level of data accuracy.

By integrating the 3500/23E module with existing control systems, operators gain real-time visibility into the condition of their machinery, allowing them to take preventive measures that enhance safety and reduce unplanned downtime.

Product Specifications

| Specification | Details |

|---|---|

| Dimensions (L x W x H) | 228 x 50 x 289 mm |

| Weight | 1.45 kg |

| Input Voltage | 24V DC ± 10% |

| Operating Temperature Range | -40°C to +85°C |

| Input Channels | 8 differential or 16 single-ended |

| Communication Protocols | Modbus, Ethernet, RS-485 |

| Data Sampling Rate | 100 kHz |

| Accuracy | ±0.1% |

| Protection | IP20 rated |

| Mounting | DIN rail mounting |

Product Applications

The 3500/23E TDI Module is designed for high-speed data acquisition and precise signal monitoring in critical industrial applications. Below are some key applications where this module is most commonly used:

-

Power Generation

In power plants, turbines, compressors, and other key machinery require constant monitoring. The 3500/23E module captures transient data that helps identify early warning signs of faults, enabling power generation facilities to take proactive actions before major issues occur.

-

Oil and Gas

The 3500/23E module is crucial for monitoring equipment such as pumps, compressors, and drilling rigs in the oil and gas sector. It captures transient signals, which help detect mechanical failures or operational inefficiencies early, improving safety and reducing the likelihood of costly shutdowns.

-

Mining and Heavy Industry

The module is used in mining and heavy industrial settings to monitor large machines like crushers, mills, and conveyors. The ability to capture transient data enables operators to prevent costly breakdowns and extend the life of expensive equipment.

-

Automotive Manufacturing

In automotive manufacturing, the 3500/23E helps monitor machinery on production lines to ensure high precision and operational efficiency. The module detects early signs of failure, which helps avoid production delays and downtime.

-

Aerospace

Aerospace manufacturers rely on the 3500/23E module to monitor critical systems such as turbines and engines. The module ensures that any signs of wear or potential issues are detected early, contributing to the reliability and safety of aerospace operations.

Product Advantages

-

High-Speed Data Acquisition

The 3500/23E module offers a data sampling rate of 100 kHz, enabling it to capture transient signals in real time with exceptional accuracy. This capability helps operators identify minor mechanical issues before they escalate into larger, more expensive problems.

-

Wide Temperature Range

The module operates in a temperature range of -40°C to +85°C, ensuring its functionality in a wide variety of industrial environments, from extreme cold to high-heat settings.

-

Compact and Lightweight Design

With dimensions of 228 x 50 x 289 mm and a weight of only 1.45 kg, the 3500/23E module is compact and lightweight, making it easy to install and integrate into existing systems, even in space-constrained areas.

-

Flexibility in Input Channels

The 3500/23E module can handle up to 8 differential or 16 single-ended input channels, offering versatility in monitoring a wide array of equipment.

-

Reliable Protection

The module is IP20 rated, providing protection from dust and other environmental factors. This ensures that it operates reliably even in challenging industrial conditions.

-

Seamless Integration

Supporting Modbus, Ethernet, and RS-485 communication protocols, the 3500/23E integrates easily into existing control systems, providing a seamless monitoring solution.

-

Predictive Maintenance

By capturing transient data, the module plays a crucial role in predictive maintenance strategies. This allows operators to detect issues early, thus reducing unplanned downtime and costly repairs.

-

Durability and Longevity

Built to withstand harsh environments, the 3500/23E module is designed for long-term performance, minimizing the need for maintenance and ensuring reliability over time.

FAQ

Q1: What is the purpose of the Bently Nevada 3500/23E module?

A1: The 3500/23E module is used to capture transient signals such as vibrations, pressure fluctuations, and temperature changes, helping to monitor and maintain the health of industrial machinery.

Q2: How many input channels does the 3500/23E module support?

A2: The 3500/23E module supports up to 8 differential or 16 single-ended input channels, providing flexibility in monitoring various machines or sensors.

Q3: What is the data sampling rate of this module?

A3: The module offers a high-speed data sampling rate of 100 kHz, ensuring real-time capture and analysis of transient data.

Q4: Can this module operate in extreme temperatures?

A4: Yes, the 3500/23E module operates in a wide temperature range of -40°C to +85°C, making it suitable for use in both hot and cold environments.

Q5: What are the communication protocols supported by the 3500/23E?

A5: The module supports Modbus, Ethernet, and RS-485 communication protocols, allowing seamless integration with various industrial control systems.

Q6: How is the 3500/23E module mounted?

A6: The 3500/23E module is designed for DIN rail mounting, making it easy to install in control panels and other industrial systems.

Q7: What kind of protection does the module provide?

A7: The 3500/23E is rated IP20, which offers protection against dust and other environmental contaminants, ensuring reliable performance in industrial settings.

Q8: What industries benefit from using the 3500/23E?

A8: The 3500/23E module is used in industries such as power generation, oil and gas, mining, automotive manufacturing, and aerospace to monitor critical machinery.

Q9: How much does the module weigh?

A9: The 3500/23E module weighs 1.45 kg, making it lightweight and easy to handle during installation and maintenance.

Q10: Is the 3500/23E module compatible with other Bently Nevada products?

A10: Yes, the 3500/23E module is fully compatible with other Bently Nevada monitoring systems, allowing for a complete and integrated machinery monitoring solution.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...