Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

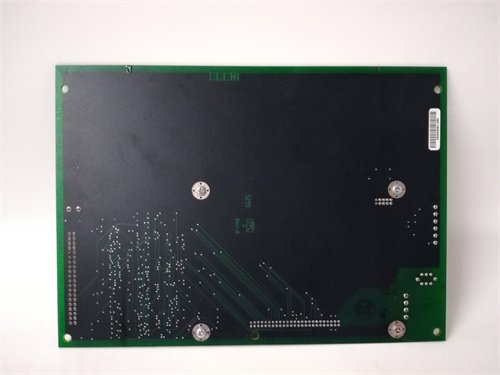

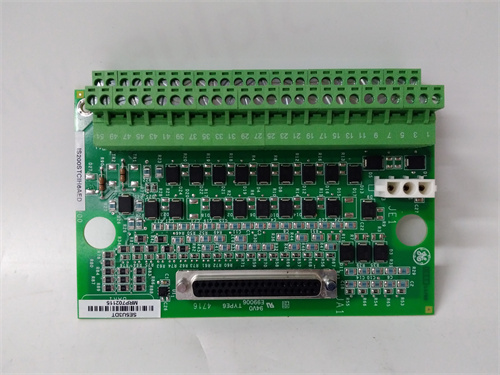

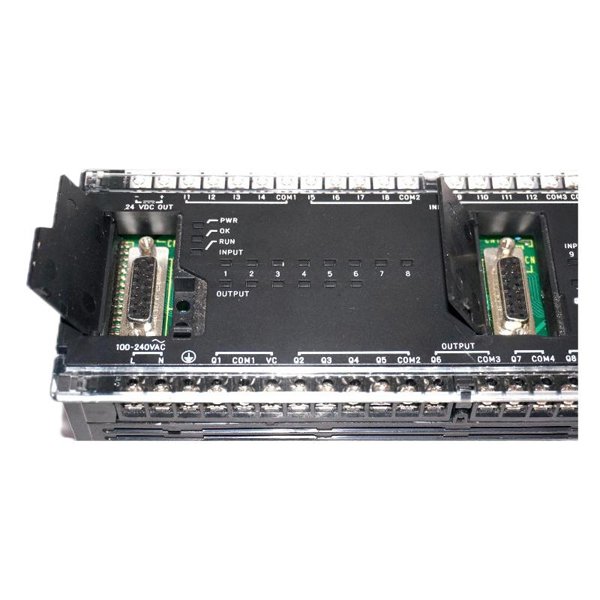

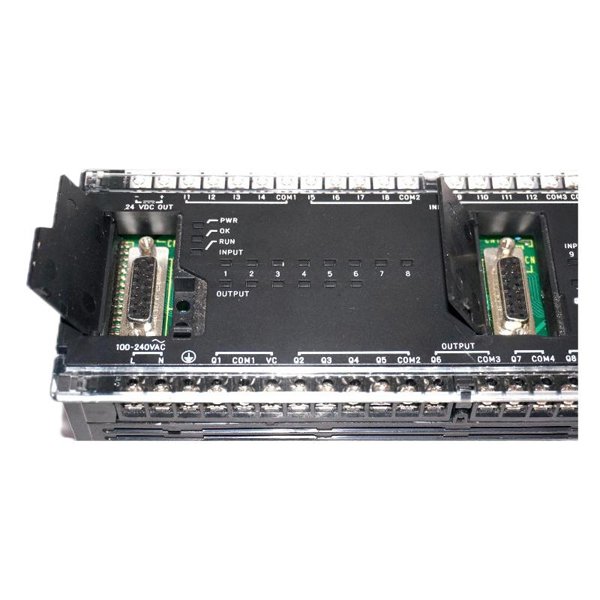

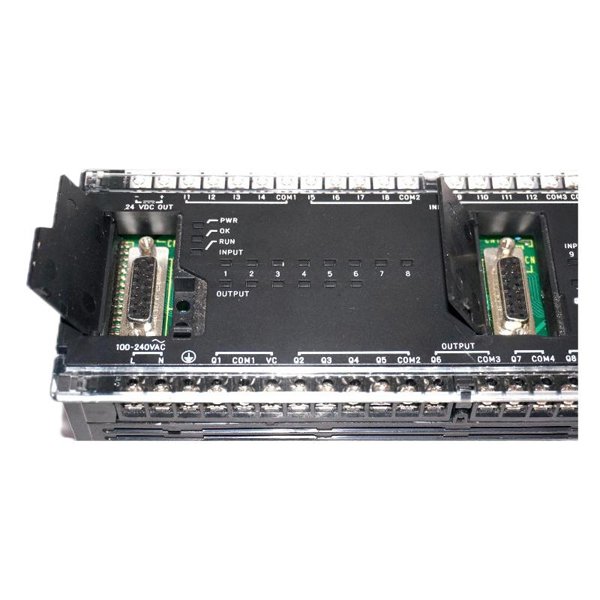

General Electric IC693UDR005 Programmable controller

Manufacturer:GE

Product Number:IC693UDR005

Condition:Programmable controller

Origin:USA

Dimensions:218 x 82.3 x 76mm

Weight:0.52kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The IC693UDR005 features a built-in CPU, 12 DC inputs, 8 relay outputs, and onboard 24VDC power supply, all in a compact housing, facilitating easy panel installation and wiring. Its compatibility with GE’s Proficy Machine Edition software ensures seamless programming, diagnostics, and system integration.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | IC693UDR005 |

| Product Series | GE Fanuc Series 90-30 Micro |

| Power Supply Voltage | 24VDC (internal power supply) |

| Digital Inputs | 12 DC inputs |

| Digital Outputs | 8 Relay outputs |

| Output Type | Relay |

| CPU Type | Embedded micro PLC CPU |

| Programming Port | RS-232 serial port |

| Memory | 1 KB user memory |

| Program Language | Ladder Logic |

| Communication Support | SNP protocol |

| Mounting | DIN-rail or panel mounted |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Dimensions (H x W x D) | 218 x 82.3 x 76mm |

| Weight | 0.52kg |

| Certifications | UL, CE, CSA certified |

| Software Compatibility | Proficy Machine Edition |

Product Applications

The GE IC693UDR005 is widely applied in various industries where compact and efficient control is essential:

-

Industrial Automation: Used in controlling conveyors, motors, and machines in factories.

-

Water Treatment Plants: Managing pumps, valves, and filtration systems.

-

Building Automation: Integrates with HVAC, lighting, and access control systems.

-

Packaging Systems: Automates sequences in bottling, labeling, or palletizing.

-

OEM Machine Control: Embedded in third-party equipment for control and monitoring.

Product Advantages

-

Compact Design: All-in-one solution with built-in I/O and power supply, minimizing wiring complexity.

-

Ease of Installation: Suitable for panel or DIN-rail mounting, reducing setup time.

-

Cost-Efficient: Eliminates need for additional modules in small-scale applications.

-

Reliability: Industrial-grade components ensure stable operation under harsh conditions.

-

Flexible Programming: Supports ladder logic via GE’s Proficy Machine Edition.

-

Global Standards Compliance: Certified for global markets, simplifying international deployment.

-

Integrated Communication: Built-in RS-232 port ensures easy connection with SCADA or HMI systems.

Frequently Asked Questions (FAQ)

Q1: What software is used to program the IC693UDR005?

A1: It is programmed using GE’s Proficy Machine Edition software.

Q2: Can this PLC be expanded with additional modules?

A2: The IC693UDR005 is designed as a compact micro PLC and does not support expansion modules.

Q3: Is the IC693UDR005 suitable for outdoor use?

A3: No, it should be installed in a controlled indoor environment within specified temperature ranges.

Q4: What is the type of output supported?

A4: This model includes 8 relay outputs suitable for switching AC or DC loads.

Q5: Does it support analog I/O?

A5: No, this unit only includes digital inputs and relay outputs.

Q6: What communication protocol does it use?

A6: It supports the SNP protocol via its serial communication port.

Q7: Is the unit UL and CE certified?

A7: Yes, it is certified for UL, CE, and CSA compliance.

Q8: Can I monitor the PLC remotely?

A8: Remote monitoring can be done via SCADA/HMI software through the RS-232 interface.

Q9: What is the maximum current for relay outputs?

A9: Typically, the relay outputs support up to 2A per channel, depending on load conditions.

Q10: Is there a built-in real-time clock?

A10: No, the IC693UDR005 does not feature an internal real-time clock.

General Electric IC693UDR005 Programmable controller

Manufacturer:GE

Product Number:IC693UDR005

Condition:Programmable controller

Origin:USA

Dimensions:218 x 82.3 x 76mm

Weight:0.52kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The IC693UDR005 features a built-in CPU, 12 DC inputs, 8 relay outputs, and onboard 24VDC power supply, all in a compact housing, facilitating easy panel installation and wiring. Its compatibility with GE’s Proficy Machine Edition software ensures seamless programming, diagnostics, and system integration.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | IC693UDR005 |

| Product Series | GE Fanuc Series 90-30 Micro |

| Power Supply Voltage | 24VDC (internal power supply) |

| Digital Inputs | 12 DC inputs |

| Digital Outputs | 8 Relay outputs |

| Output Type | Relay |

| CPU Type | Embedded micro PLC CPU |

| Programming Port | RS-232 serial port |

| Memory | 1 KB user memory |

| Program Language | Ladder Logic |

| Communication Support | SNP protocol |

| Mounting | DIN-rail or panel mounted |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Dimensions (H x W x D) | 218 x 82.3 x 76mm |

| Weight | 0.52kg |

| Certifications | UL, CE, CSA certified |

| Software Compatibility | Proficy Machine Edition |

Product Applications

The GE IC693UDR005 is widely applied in various industries where compact and efficient control is essential:

-

Industrial Automation: Used in controlling conveyors, motors, and machines in factories.

-

Water Treatment Plants: Managing pumps, valves, and filtration systems.

-

Building Automation: Integrates with HVAC, lighting, and access control systems.

-

Packaging Systems: Automates sequences in bottling, labeling, or palletizing.

-

OEM Machine Control: Embedded in third-party equipment for control and monitoring.

Product Advantages

-

Compact Design: All-in-one solution with built-in I/O and power supply, minimizing wiring complexity.

-

Ease of Installation: Suitable for panel or DIN-rail mounting, reducing setup time.

-

Cost-Efficient: Eliminates need for additional modules in small-scale applications.

-

Reliability: Industrial-grade components ensure stable operation under harsh conditions.

-

Flexible Programming: Supports ladder logic via GE’s Proficy Machine Edition.

-

Global Standards Compliance: Certified for global markets, simplifying international deployment.

-

Integrated Communication: Built-in RS-232 port ensures easy connection with SCADA or HMI systems.

Frequently Asked Questions (FAQ)

Q1: What software is used to program the IC693UDR005?

A1: It is programmed using GE’s Proficy Machine Edition software.

Q2: Can this PLC be expanded with additional modules?

A2: The IC693UDR005 is designed as a compact micro PLC and does not support expansion modules.

Q3: Is the IC693UDR005 suitable for outdoor use?

A3: No, it should be installed in a controlled indoor environment within specified temperature ranges.

Q4: What is the type of output supported?

A4: This model includes 8 relay outputs suitable for switching AC or DC loads.

Q5: Does it support analog I/O?

A5: No, this unit only includes digital inputs and relay outputs.

Q6: What communication protocol does it use?

A6: It supports the SNP protocol via its serial communication port.

Q7: Is the unit UL and CE certified?

A7: Yes, it is certified for UL, CE, and CSA compliance.

Q8: Can I monitor the PLC remotely?

A8: Remote monitoring can be done via SCADA/HMI software through the RS-232 interface.

Q9: What is the maximum current for relay outputs?

A9: Typically, the relay outputs support up to 2A per channel, depending on load conditions.

Q10: Is there a built-in real-time clock?

A10: No, the IC693UDR005 does not feature an internal real-time clock.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...