Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

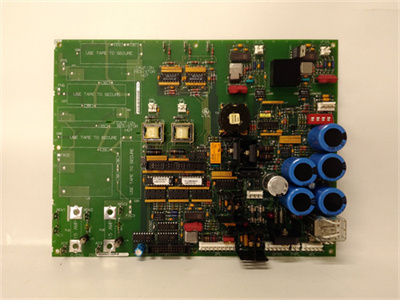

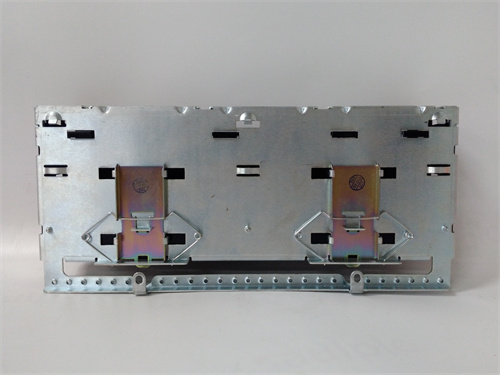

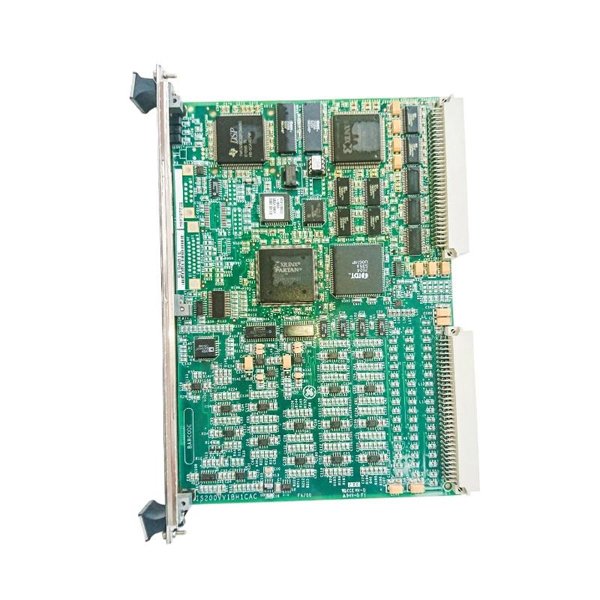

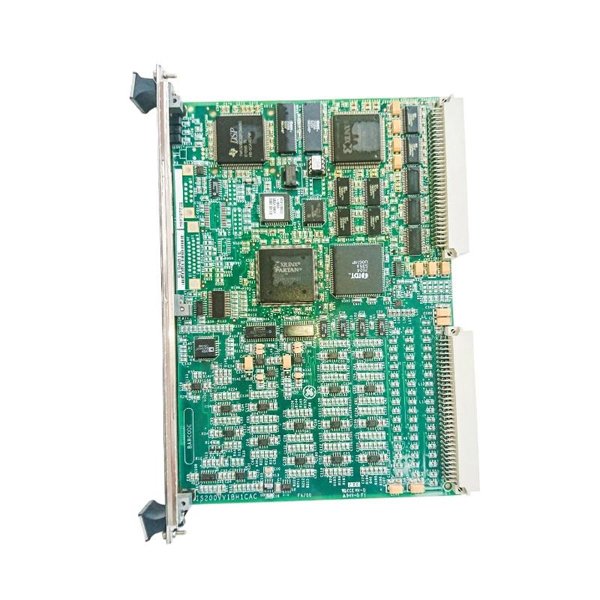

General Electric IS200VVIBH1 Vibration Monitor Board

Manufacturer:GE

Product Number:IS200VVIBH1

Product Type:Vibration Monitor Board

Origin:USA

Dimensions:240 x 110 x 25 mm

Weight:0.5 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

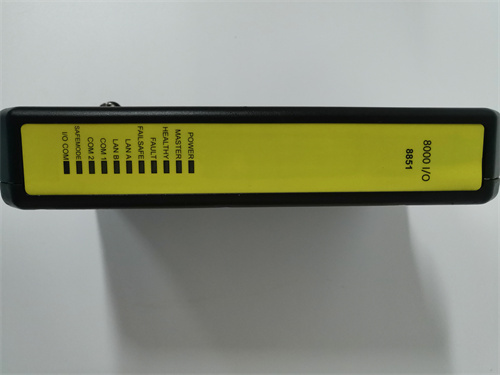

The GE IS200VVIBH1 Vibration Monitor Board is a high-performance module designed to provide precise monitoring and analysis of vibration levels in critical rotating machinery. Integrated into GE’s Mark VI and Mark VIe control systems, it plays a vital role in protecting turbines, compressors, and generators by ensuring real-time detection of abnormal vibration patterns. This board interfaces with proximity probes and accelerometers, converting raw vibration signals into actionable diagnostic data.

Engineered with advanced digital signal processing, the IS200VVIBH1 delivers accurate measurements, allowing operators to implement predictive maintenance strategies and avoid costly unplanned shutdowns. Its robust VME architecture ensures reliable operation in demanding industrial environments such as power generation, oil & gas, and heavy manufacturing.

Product Specifications

| Parameter | Details |

|---|---|

| Model | GE IS200VVIBH1 |

| Type | Vibration Monitor Board |

| System Compatibility | GE Mark VI / Mark VIe Control Systems |

| Sensor Interfaces | Proximity probes, accelerometers |

| Signal Processing | Real-time digital signal processing |

| Vibration Measurement Range | Configurable depending on sensor type |

| Outputs | Conditioned signals for protection and monitoring |

| Diagnostics | Built-in self-test and fault detection |

| Redundancy Support | Compatible with redundant architectures |

| Communication Bus | VME backplane |

| Power Supply | 28 VDC nominal |

| Operating Temperature | 0°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Compliance | CE, UL, IEC, RoHS |

| Dimensions (L x W x H) | 240 x 110 x 25 mm |

| Weight | 0.5 kg |

Product Applications

-

Turbine Monitoring: Continuous vibration monitoring of steam and gas turbines to prevent damage.

-

Compressor Protection: Detects abnormal vibration levels in critical compressor systems.

-

Generator Condition Monitoring: Ensures stable operation of generators by identifying misalignments or imbalance.

-

Industrial Machinery: Protects pumps, motors, and other rotating equipment in heavy industry.

-

Predictive Maintenance Systems: Provides early warning for maintenance planning to reduce downtime.

-

Integration with Control Systems: Works seamlessly with GE Mark VI/VIe platforms for comprehensive plant protection.

Product Advantages

-

High-Accuracy Vibration Measurement: Offers precise detection of vibration levels using advanced DSP.

-

Real-Time Monitoring: Ensures immediate response to abnormal vibration events.

-

Sensor Versatility: Supports multiple types of vibration sensors including proximity probes and accelerometers.

-

Fault Diagnostics: Built-in self-testing and monitoring capabilities to ensure system reliability.

-

Seamless Integration: Designed for direct compatibility with GE Mark VI/VIe systems.

-

Robust Industrial Design: Engineered for high reliability in harsh operating environments.

FAQ

-

What types of sensors can the IS200VVIBH1 interface with?

It supports proximity probes and accelerometers for comprehensive vibration monitoring.

-

Does the board perform real-time digital signal processing?

Yes, it uses advanced DSP algorithms to ensure accurate and immediate analysis of vibration data.

-

Is the IS200VVIBH1 compatible with redundant control system architectures?

It is fully compatible with dual and triple modular redundancy configurations.

-

Can the board be used for both turbines and compressors?

Yes, it is designed for a wide range of rotating machinery including turbines, compressors, and generators.

-

Does the board provide conditioned outputs for protection systems?

It delivers processed signals to trigger protection relays or integrate with plant DCS systems.

-

What communication interface does it use?

The IS200VVIBH1 communicates through a VME backplane for high-speed data transfer.

-

Can it detect both high and low-frequency vibration patterns?

Yes, the board can process a wide spectrum of vibration frequencies depending on sensor configuration.

-

Is predictive maintenance supported by this board?

It enables predictive maintenance strategies by providing early warnings based on vibration trends.

-

Does the board include self-diagnostic features?

Yes, it includes built-in self-test functions and fault detection to ensure operational reliability.

-

What power input does the IS200VVIBH1 require?

The board operates on a nominal 28 VDC power supply.

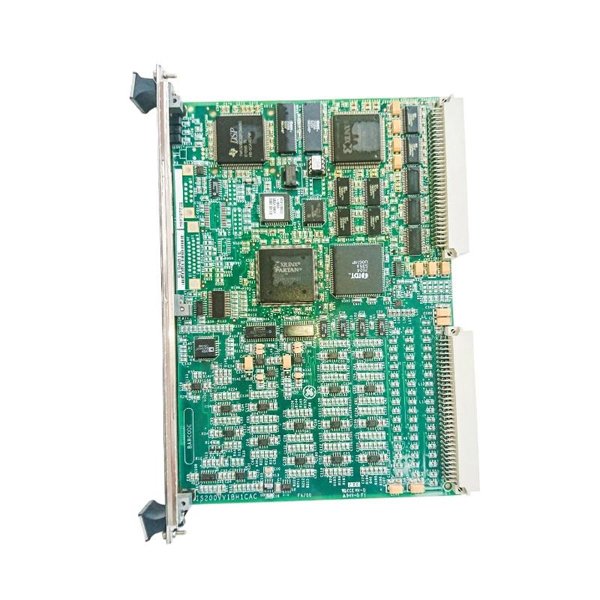

General Electric IS200VVIBH1 Vibration Monitor Board

Manufacturer:GE

Product Number:IS200VVIBH1

Product Type:Vibration Monitor Board

Origin:USA

Dimensions:240 x 110 x 25 mm

Weight:0.5 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VVIBH1 Vibration Monitor Board is a high-performance module designed to provide precise monitoring and analysis of vibration levels in critical rotating machinery. Integrated into GE’s Mark VI and Mark VIe control systems, it plays a vital role in protecting turbines, compressors, and generators by ensuring real-time detection of abnormal vibration patterns. This board interfaces with proximity probes and accelerometers, converting raw vibration signals into actionable diagnostic data.

Engineered with advanced digital signal processing, the IS200VVIBH1 delivers accurate measurements, allowing operators to implement predictive maintenance strategies and avoid costly unplanned shutdowns. Its robust VME architecture ensures reliable operation in demanding industrial environments such as power generation, oil & gas, and heavy manufacturing.

Product Specifications

| Parameter | Details |

|---|---|

| Model | GE IS200VVIBH1 |

| Type | Vibration Monitor Board |

| System Compatibility | GE Mark VI / Mark VIe Control Systems |

| Sensor Interfaces | Proximity probes, accelerometers |

| Signal Processing | Real-time digital signal processing |

| Vibration Measurement Range | Configurable depending on sensor type |

| Outputs | Conditioned signals for protection and monitoring |

| Diagnostics | Built-in self-test and fault detection |

| Redundancy Support | Compatible with redundant architectures |

| Communication Bus | VME backplane |

| Power Supply | 28 VDC nominal |

| Operating Temperature | 0°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Compliance | CE, UL, IEC, RoHS |

| Dimensions (L x W x H) | 240 x 110 x 25 mm |

| Weight | 0.5 kg |

Product Applications

-

Turbine Monitoring: Continuous vibration monitoring of steam and gas turbines to prevent damage.

-

Compressor Protection: Detects abnormal vibration levels in critical compressor systems.

-

Generator Condition Monitoring: Ensures stable operation of generators by identifying misalignments or imbalance.

-

Industrial Machinery: Protects pumps, motors, and other rotating equipment in heavy industry.

-

Predictive Maintenance Systems: Provides early warning for maintenance planning to reduce downtime.

-

Integration with Control Systems: Works seamlessly with GE Mark VI/VIe platforms for comprehensive plant protection.

Product Advantages

-

High-Accuracy Vibration Measurement: Offers precise detection of vibration levels using advanced DSP.

-

Real-Time Monitoring: Ensures immediate response to abnormal vibration events.

-

Sensor Versatility: Supports multiple types of vibration sensors including proximity probes and accelerometers.

-

Fault Diagnostics: Built-in self-testing and monitoring capabilities to ensure system reliability.

-

Seamless Integration: Designed for direct compatibility with GE Mark VI/VIe systems.

-

Robust Industrial Design: Engineered for high reliability in harsh operating environments.

FAQ

-

What types of sensors can the IS200VVIBH1 interface with?

It supports proximity probes and accelerometers for comprehensive vibration monitoring.

-

Does the board perform real-time digital signal processing?

Yes, it uses advanced DSP algorithms to ensure accurate and immediate analysis of vibration data.

-

Is the IS200VVIBH1 compatible with redundant control system architectures?

It is fully compatible with dual and triple modular redundancy configurations.

-

Can the board be used for both turbines and compressors?

Yes, it is designed for a wide range of rotating machinery including turbines, compressors, and generators.

-

Does the board provide conditioned outputs for protection systems?

It delivers processed signals to trigger protection relays or integrate with plant DCS systems.

-

What communication interface does it use?

The IS200VVIBH1 communicates through a VME backplane for high-speed data transfer.

-

Can it detect both high and low-frequency vibration patterns?

Yes, the board can process a wide spectrum of vibration frequencies depending on sensor configuration.

-

Is predictive maintenance supported by this board?

It enables predictive maintenance strategies by providing early warnings based on vibration trends.

-

Does the board include self-diagnostic features?

Yes, it includes built-in self-test functions and fault detection to ensure operational reliability.

-

What power input does the IS200VVIBH1 require?

The board operates on a nominal 28 VDC power supply.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...