Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

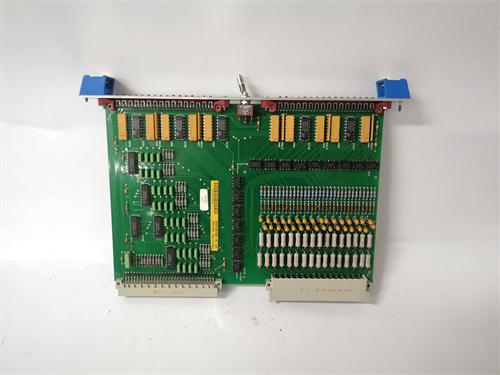

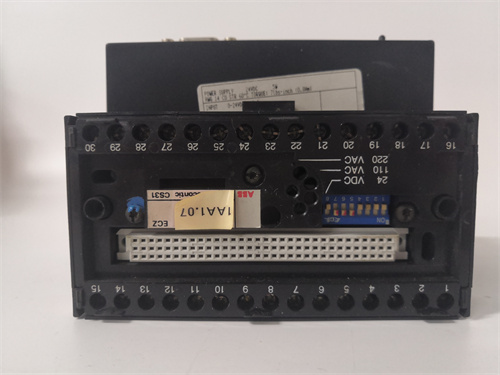

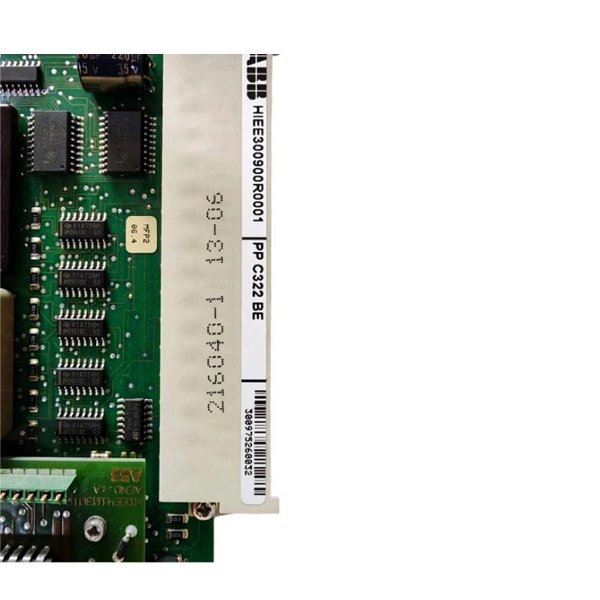

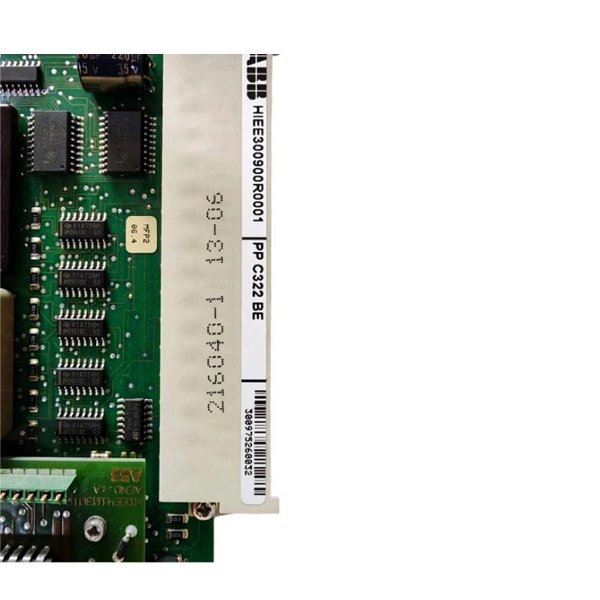

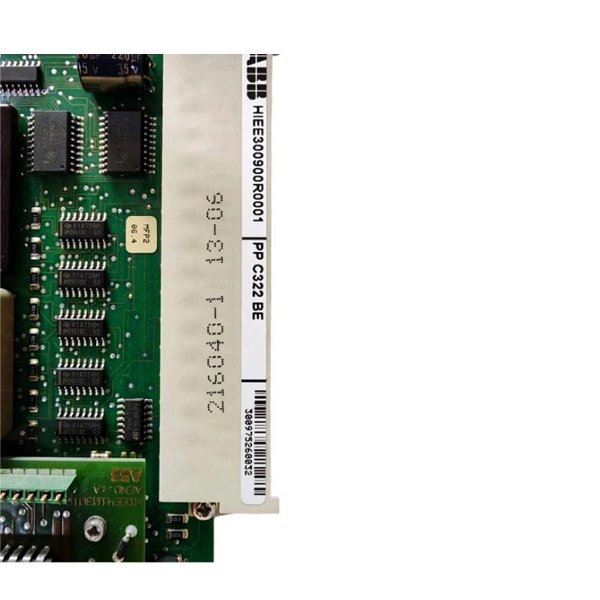

ABB PP C322 BE01 HIEE300900R0001 Processor Module

Manufacturer:ABB

Product Number:PP C322 BE01 HIEE300900R0001

Product Type:Processor Module

Origin:Sweden

Dimensions:29 x 29 x 29 mm

Weight:1.149 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PP C322 BE01 (Part Number: HIEE300900R0001) is a powerful processor module engineered to serve as a central computing unit within ABB’s Symphony and Advant control systems. Designed for complex industrial control tasks, this processor module is built on robust hardware and firmware architecture, enabling precise execution of real-time control logic, seamless communication, and fault-tolerant automation operations.

It plays a crucial role in managing signal processing, executing embedded control algorithms, handling input/output operations, and interfacing with other system modules. Its optimized instruction cycle and integrated communication features ensure efficient coordination within distributed control systems (DCS).

This processor module is widely used across industries where continuous and accurate process control is vital, such as power generation, oil & gas, water treatment, and chemical processing environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | PP C322 BE01 |

| Part Number | HIEE300900R0001 |

| Function | Central processor module for real-time control execution |

| Processor Type | High-speed 32-bit RISC embedded processor |

| Clock Frequency | Approximately 66 MHz |

| Internal RAM | 4 MB Static RAM |

| Non-Volatile Memory | 8 MB Flash or EEPROM |

| Backplane Communication | Supported via high-speed bus interface |

| Supported Protocols | ABB proprietary bus, Modbus, TCP/IP, Profibus |

| Digital I/O Handling | Yes, via I/O rack connection |

| Analog Signal Processing | Indirect through peripheral modules |

| Diagnostic Features | Built-in self-test, LED status indicators, watchdog timer |

| Redundancy Capability | Yes, supports hot standby and redundancy architecture |

| Power Supply Input | 24 VDC nominal (range 18–36 VDC) |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Cooling Method | Passive convection cooling |

| Mounting Style | DIN rail or backplane-mounted in system rack |

| Dimensions (W × H × D) | 29 x 29 x 29 mm |

| Weight | 1.149 kg |

| Certifications | CE, RoHS, IEC 61131-2, UL, CSA |

Applications

The ABB PP C322 BE01 processor module is widely adopted in complex control environments requiring real-time computing and reliable data communication. Primary applications include:

-

Thermal and Combined-Cycle Power Plants

Acts as a logic controller for boiler operation, turbine sequencing, and plant-wide synchronization.

-

Oil & Gas Processing Units

Manages valve logic, compressor control, pressure loops, and integrates with SCADA for remote monitoring.

-

Water and Wastewater Treatment Plants

Executes flow regulation, chemical dosing control, and filtration automation sequences.

-

Chemical and Petrochemical Facilities

Controls batch processing units, temperature and pressure interlocks, and production line sequencing.

-

Metals & Mining Operations

Orchestrates motor synchronization, furnace control, and safety logic circuits.

-

Manufacturing Automation Systems

Provides deterministic cycle timing and interface coordination between robotics, sensors, and PLCs.

Product Advantages

-

High-Performance Processing

Designed for mission-critical industrial control applications requiring fast and deterministic computing cycles.

-

Flexible System Integration

Compatible with various ABB DCS and I/O systems, supporting legacy and modern architecture simultaneously.

-

Robust Communication Protocols

Equipped with multiple bus support including ABB’s proprietary and open protocols like Modbus and TCP/IP.

-

Enhanced Diagnostics

Integrated LED indicators, internal watchdog, and self-diagnosis features support faster troubleshooting.

-

Hot-Standby Redundancy

Supports redundant configurations with auto-switchover, ensuring high availability and minimized downtime.

-

Industrial-Grade Design

Operates reliably in challenging environments with resistance to temperature variations and EMC disturbances.

-

Expandable Architecture

Easily integrates with additional I/O, HMI, or safety modules through backplane and communication ports.

-

Long-Term Lifecycle Support

Backed by ABB’s extensive service and replacement program, ensuring longevity and software compatibility.

-

Seamless Upgrades

Drop-in replacement capabilities for legacy units within the same system family for minimal system downtime.

-

Optimized for Low Maintenance

Passive cooling and modular component layout reduce the need for frequent servicing or part replacement.

FAQs

-

Does the PP C322 BE01 support real-time multitasking for control logic?

Yes, it supports real-time multitasking through its embedded RTOS and optimized memory access.

-

How is memory allocated for user programs and system functions?

Memory is divided into firmware, diagnostic logs, user logic, and I/O tables; exact allocation is configurable.

-

Is the module compatible with ABB’s Composer and Control Builder tools?

Yes, it can be programmed and monitored via Composer and ABB Control Builder platforms.

-

What communication isolation is implemented for noise immunity?

The module features galvanic isolation between communication ports and the internal CPU to enhance reliability.

-

Can the processor operate in a redundant CPU pair configuration?

Yes, the unit supports dual-CPU hot-standby configurations with automatic synchronization.

-

Is firmware upgradeable without removing the module from the system?

Yes, firmware upgrades can be done in-situ using ABB engineering tools and serial or Ethernet connections.

-

Does it support time-synchronized control applications (e.g., IEEE 1588)?

Time synchronization is supported when combined with ABB network time sources or compatible modules.

-

How are I/O signal updates synchronized with the CPU scan cycle?

I/O signals are scanned and updated through high-speed backplane communication within each scan cycle.

-

What safety features are embedded for fail-safe operations?

Features include internal watchdog, diagnostic RAM checks, voltage monitoring, and fault latching outputs.

-

How is communication handled in noisy industrial environments?

Through shielded, optically isolated communication lines and surge-protected input/output interfaces.

ABB PP C322 BE01 HIEE300900R0001 Processor Module

Manufacturer:ABB

Product Number:PP C322 BE01 HIEE300900R0001

Product Type:Processor Module

Origin:Sweden

Dimensions:29 x 29 x 29 mm

Weight:1.149 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PP C322 BE01 (Part Number: HIEE300900R0001) is a powerful processor module engineered to serve as a central computing unit within ABB’s Symphony and Advant control systems. Designed for complex industrial control tasks, this processor module is built on robust hardware and firmware architecture, enabling precise execution of real-time control logic, seamless communication, and fault-tolerant automation operations.

It plays a crucial role in managing signal processing, executing embedded control algorithms, handling input/output operations, and interfacing with other system modules. Its optimized instruction cycle and integrated communication features ensure efficient coordination within distributed control systems (DCS).

This processor module is widely used across industries where continuous and accurate process control is vital, such as power generation, oil & gas, water treatment, and chemical processing environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | PP C322 BE01 |

| Part Number | HIEE300900R0001 |

| Function | Central processor module for real-time control execution |

| Processor Type | High-speed 32-bit RISC embedded processor |

| Clock Frequency | Approximately 66 MHz |

| Internal RAM | 4 MB Static RAM |

| Non-Volatile Memory | 8 MB Flash or EEPROM |

| Backplane Communication | Supported via high-speed bus interface |

| Supported Protocols | ABB proprietary bus, Modbus, TCP/IP, Profibus |

| Digital I/O Handling | Yes, via I/O rack connection |

| Analog Signal Processing | Indirect through peripheral modules |

| Diagnostic Features | Built-in self-test, LED status indicators, watchdog timer |

| Redundancy Capability | Yes, supports hot standby and redundancy architecture |

| Power Supply Input | 24 VDC nominal (range 18–36 VDC) |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Cooling Method | Passive convection cooling |

| Mounting Style | DIN rail or backplane-mounted in system rack |

| Dimensions (W × H × D) | 29 x 29 x 29 mm |

| Weight | 1.149 kg |

| Certifications | CE, RoHS, IEC 61131-2, UL, CSA |

Applications

The ABB PP C322 BE01 processor module is widely adopted in complex control environments requiring real-time computing and reliable data communication. Primary applications include:

-

Thermal and Combined-Cycle Power Plants

Acts as a logic controller for boiler operation, turbine sequencing, and plant-wide synchronization.

-

Oil & Gas Processing Units

Manages valve logic, compressor control, pressure loops, and integrates with SCADA for remote monitoring.

-

Water and Wastewater Treatment Plants

Executes flow regulation, chemical dosing control, and filtration automation sequences.

-

Chemical and Petrochemical Facilities

Controls batch processing units, temperature and pressure interlocks, and production line sequencing.

-

Metals & Mining Operations

Orchestrates motor synchronization, furnace control, and safety logic circuits.

-

Manufacturing Automation Systems

Provides deterministic cycle timing and interface coordination between robotics, sensors, and PLCs.

Product Advantages

-

High-Performance Processing

Designed for mission-critical industrial control applications requiring fast and deterministic computing cycles.

-

Flexible System Integration

Compatible with various ABB DCS and I/O systems, supporting legacy and modern architecture simultaneously.

-

Robust Communication Protocols

Equipped with multiple bus support including ABB’s proprietary and open protocols like Modbus and TCP/IP.

-

Enhanced Diagnostics

Integrated LED indicators, internal watchdog, and self-diagnosis features support faster troubleshooting.

-

Hot-Standby Redundancy

Supports redundant configurations with auto-switchover, ensuring high availability and minimized downtime.

-

Industrial-Grade Design

Operates reliably in challenging environments with resistance to temperature variations and EMC disturbances.

-

Expandable Architecture

Easily integrates with additional I/O, HMI, or safety modules through backplane and communication ports.

-

Long-Term Lifecycle Support

Backed by ABB’s extensive service and replacement program, ensuring longevity and software compatibility.

-

Seamless Upgrades

Drop-in replacement capabilities for legacy units within the same system family for minimal system downtime.

-

Optimized for Low Maintenance

Passive cooling and modular component layout reduce the need for frequent servicing or part replacement.

FAQs

-

Does the PP C322 BE01 support real-time multitasking for control logic?

Yes, it supports real-time multitasking through its embedded RTOS and optimized memory access.

-

How is memory allocated for user programs and system functions?

Memory is divided into firmware, diagnostic logs, user logic, and I/O tables; exact allocation is configurable.

-

Is the module compatible with ABB’s Composer and Control Builder tools?

Yes, it can be programmed and monitored via Composer and ABB Control Builder platforms.

-

What communication isolation is implemented for noise immunity?

The module features galvanic isolation between communication ports and the internal CPU to enhance reliability.

-

Can the processor operate in a redundant CPU pair configuration?

Yes, the unit supports dual-CPU hot-standby configurations with automatic synchronization.

-

Is firmware upgradeable without removing the module from the system?

Yes, firmware upgrades can be done in-situ using ABB engineering tools and serial or Ethernet connections.

-

Does it support time-synchronized control applications (e.g., IEEE 1588)?

Time synchronization is supported when combined with ABB network time sources or compatible modules.

-

How are I/O signal updates synchronized with the CPU scan cycle?

I/O signals are scanned and updated through high-speed backplane communication within each scan cycle.

-

What safety features are embedded for fail-safe operations?

Features include internal watchdog, diagnostic RAM checks, voltage monitoring, and fault latching outputs.

-

How is communication handled in noisy industrial environments?

Through shielded, optically isolated communication lines and surge-protected input/output interfaces.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...