Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

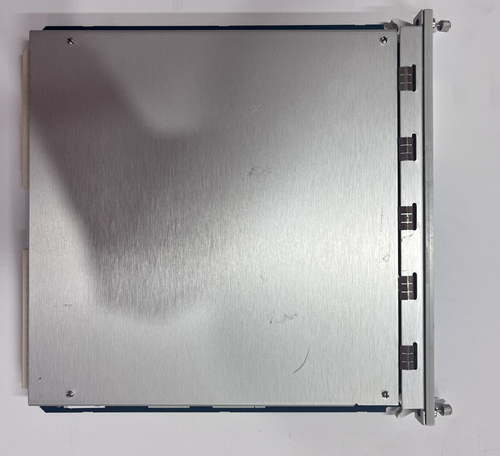

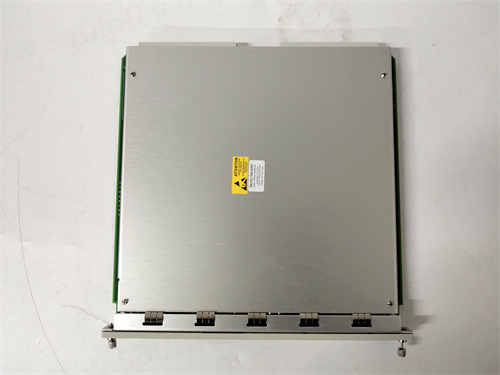

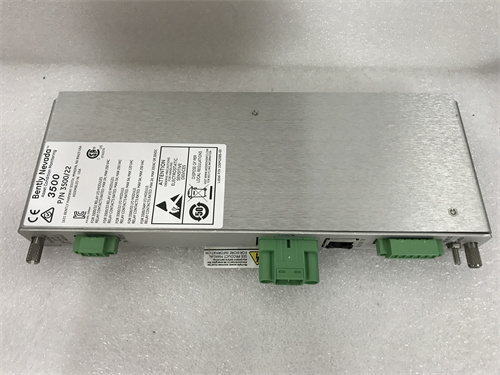

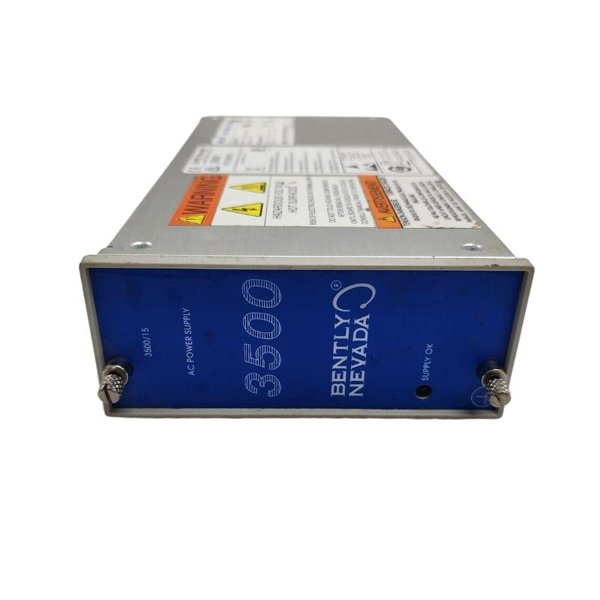

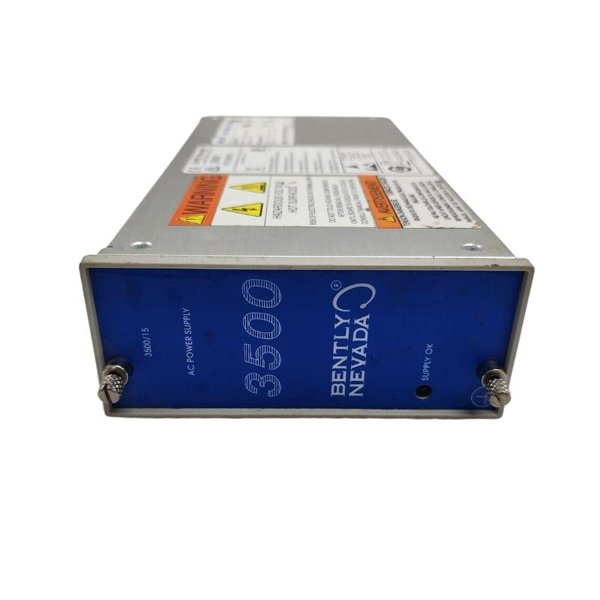

Bently Nevada 3500/15-03-00-00 Power Supply

Manufacturer:Bently Nevada

Product Number:3500/15-03-00-00

Product Type:Power Supply

Origin:USA

Dimensions:120.7 x 50.8 x 251.5mm

Weight :1.39 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The technical specifications of the Bently Nevada 3500/15-03-00-00 are as follows:

| Parameter | Specification |

|---|---|

| Model Number | 3500/15-03-00-00 |

| Input Voltage | 18–30 VDC |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Output Signal | 4–20 mA, ±10 VDC (configurable) |

| Frequency Response | 0.5 Hz to 12 kHz |

| Probe Type | Proximity Probe (Eddy Current) |

| Dimensions | 120.7 x 50.8 x 251.5mm |

| Weight | 1.39 kg |

| Enclosure Rating | IP67 (Dustproof and Waterproof) |

| Compliance | ATEX, IECEx, SIL 2 |

Product Applications

The Bently Nevada 3500/15-03-00-00 is utilized in a wide range of industrial applications, including:

-

Turbine Monitoring: Ensures safe operation of steam and gas turbines by detecting vibration and axial displacement.

-

Compressor Protection: Monitors radial and thrust positions in centrifugal and reciprocating compressors.

-

Pump Systems: Detects bearing wear and misalignment in high-speed pumps.

-

Electric Motors: Provides early warning of rotor imbalances or mechanical faults.

-

Power Generation: Used in hydroelectric and nuclear plants for critical machinery safeguarding.

Product Advantages

-

High Accuracy: Delivers precise measurements for vibration and position monitoring.

-

Durability: Built to withstand extreme temperatures, humidity, and mechanical stress.

-

Easy Integration: Compatible with existing Bently Nevada 3500 monitoring systems.

-

Flexible Configuration: Supports multiple output signals for diverse industrial needs.

-

Safety Compliance: Meets ATEX and SIL 2 standards for hazardous environments.

-

Low Maintenance: Designed for long-term reliability with minimal servicing.

FAQ

-

What is the purpose of the 3500/15-03-00-00 module?

It is used for radial vibration and axial position monitoring in rotating machinery.

-

What type of probe is compatible with this module?

It works with eddy current proximity probes (e.g., 3300 series probes).

-

Can this module operate in explosive environments?

Yes, it is ATEX and IECEx certified for hazardous areas.

-

What is the operating voltage range?

18–30 VDC.

-

How is the output signal configured?

It can be set to 4–20 mA or ±10 VDC via software.

-

What is the frequency response range?

0.5 Hz to 12 kHz.

-

Is the module waterproof?

Yes, it has an IP67 rating for dust and water resistance.

-

What industries commonly use this product?

Oil & gas, power generation, chemical processing, and manufacturing.

-

Does it require regular calibration?

Periodic calibration is recommended for optimal performance.

-

Can it be integrated with third-party monitoring systems?

Yes, it supports standard industrial communication protocols.

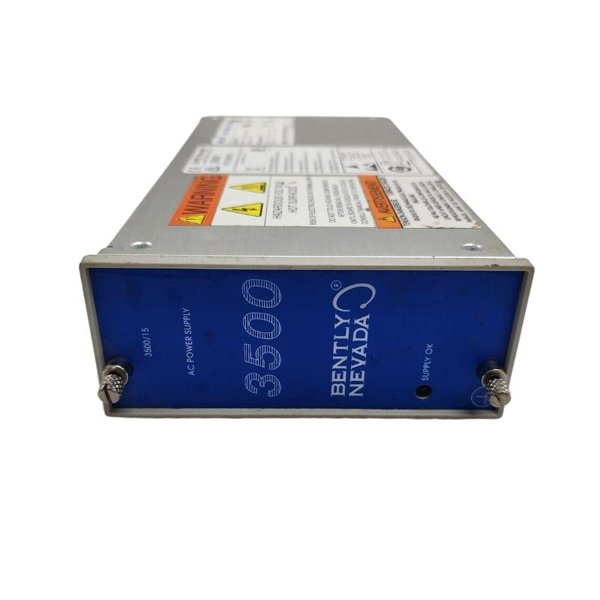

Bently Nevada 3500/15-03-00-00 Power Supply

Manufacturer:Bently Nevada

Product Number:3500/15-03-00-00

Product Type:Power Supply

Origin:USA

Dimensions:120.7 x 50.8 x 251.5mm

Weight :1.39 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The technical specifications of the Bently Nevada 3500/15-03-00-00 are as follows:

| Parameter | Specification |

|---|---|

| Model Number | 3500/15-03-00-00 |

| Input Voltage | 18–30 VDC |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Output Signal | 4–20 mA, ±10 VDC (configurable) |

| Frequency Response | 0.5 Hz to 12 kHz |

| Probe Type | Proximity Probe (Eddy Current) |

| Dimensions | 120.7 x 50.8 x 251.5mm |

| Weight | 1.39 kg |

| Enclosure Rating | IP67 (Dustproof and Waterproof) |

| Compliance | ATEX, IECEx, SIL 2 |

Product Applications

The Bently Nevada 3500/15-03-00-00 is utilized in a wide range of industrial applications, including:

-

Turbine Monitoring: Ensures safe operation of steam and gas turbines by detecting vibration and axial displacement.

-

Compressor Protection: Monitors radial and thrust positions in centrifugal and reciprocating compressors.

-

Pump Systems: Detects bearing wear and misalignment in high-speed pumps.

-

Electric Motors: Provides early warning of rotor imbalances or mechanical faults.

-

Power Generation: Used in hydroelectric and nuclear plants for critical machinery safeguarding.

Product Advantages

-

High Accuracy: Delivers precise measurements for vibration and position monitoring.

-

Durability: Built to withstand extreme temperatures, humidity, and mechanical stress.

-

Easy Integration: Compatible with existing Bently Nevada 3500 monitoring systems.

-

Flexible Configuration: Supports multiple output signals for diverse industrial needs.

-

Safety Compliance: Meets ATEX and SIL 2 standards for hazardous environments.

-

Low Maintenance: Designed for long-term reliability with minimal servicing.

FAQ

-

What is the purpose of the 3500/15-03-00-00 module?

It is used for radial vibration and axial position monitoring in rotating machinery.

-

What type of probe is compatible with this module?

It works with eddy current proximity probes (e.g., 3300 series probes).

-

Can this module operate in explosive environments?

Yes, it is ATEX and IECEx certified for hazardous areas.

-

What is the operating voltage range?

18–30 VDC.

-

How is the output signal configured?

It can be set to 4–20 mA or ±10 VDC via software.

-

What is the frequency response range?

0.5 Hz to 12 kHz.

-

Is the module waterproof?

Yes, it has an IP67 rating for dust and water resistance.

-

What industries commonly use this product?

Oil & gas, power generation, chemical processing, and manufacturing.

-

Does it require regular calibration?

Periodic calibration is recommended for optimal performance.

-

Can it be integrated with third-party monitoring systems?

Yes, it supports standard industrial communication protocols.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...