Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

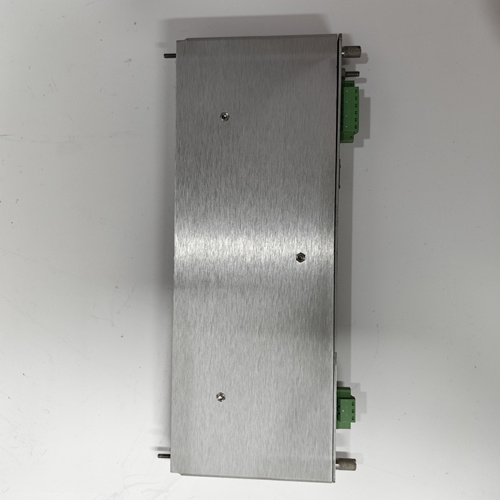

Bently Nevada 330101-00-16-10-02-00 3300 XL 8 mm Probe

Manufacturer:Bently Nevada

Product Number:330101-00-16-10-02-

Product Type:3300 XL 8 mm Probe

Origin:USA

Dimensions:1.0 meter

Weight:0.323 kg

Views:92

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300 XL 8 mm Probe is a key component in the 3300 XL Proximity Transducer System, designed for high-precision vibration and position measurement applications. This system is primarily used in fluid-film bearing machines and provides accurate, real-time data for vibration and position monitoring. The 3300 XL system includes the 8 mm probe, extension cables, and a Proximitor sensor, all of which are fully interchangeable and backward-compatible with non-XL 3300 components.

Product Specifications

| Specification | Details |

|---|---|

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Tip Material | Polyphenylene sulfide (PPS) |

| Probe Case Material | AISI 303 or 304 stainless steel (SST) |

| Electrical Input | Accepts one non-contacting 3300-series 5 mm, 3300 XL 8 mm probe |

| Power Requirements | -17.5 Vdc to -26 Vdc with a maximum 12 mA consumption |

| Nominal Probe DC Resistance | 7.59 ± 0.50 Ω at 1 meter length |

| Linear Range | 2 mm (80 mils) |

| Recommended Gap Setting | -9 Vdc (approximately 1.27 mm or 50 mils) |

| Connector Material | Gold-plated brass or gold-plated beryllium copper |

| Extension Cable Length | Available in lengths from 0.5 meters to 9 meters |

| Temperature Range (Probe) | -52°C to +177°C (-62°F to +350°F) |

| Temperature Range (Cable) | -52°C to +177°C (-62°F to +350°F) |

| Environmental Humidity | Less than 3% change in average scale factor (ASF) at 93% humidity |

Product Applications

The 3300 XL 8 mm Probe is used in a variety of industrial settings where precise vibration and position monitoring is necessary. Key applications include:

-

Vibration Monitoring: For detecting the condition of machines operating with fluid-film bearings.

-

Position Monitoring: Accurate measurement of position for rotating equipment.

-

Keyphasor Reference & Speed Measurement: Used in overspeed protection and speed measurement systems.

-

API 670 Compliance: Meets API 670 standards for mechanical configuration, range, and accuracy.

Product Advantages

-

High Precision: Delivers accurate vibration and position measurements, improving machine reliability.

-

Robust Design: The 8 mm probe has a robust, rugged design that can withstand harsh industrial environments.

-

Interchangeability: Fully compatible with both 3300 XL and non-XL components.

-

Enhanced RFI/EMI Immunity: The Proximitor sensor has improved immunity to electromagnetic and radio frequency interference, ensuring reliability in diverse environments.

-

Flexibility in Installation: The components offer flexibility in mounting configurations, including DIN-rail and panel mounts.

-

Low Maintenance: The ClickLoc connectors and enhanced design eliminate the need for frequent recalibration or component matching.

-

Extended Temperature Range: Available with an extended temperature range for use in high-heat environments (up to 425°F for probes).

FAQ

-

What is the maximum operating temperature of the Bently Nevada 3300 XL 8 mm Probe?

-

The standard probe can operate from -52°C to +177°C, and an extended range probe can operate up to +218°C for the probe tip and +260°C for the cable.

-

-

What is the recommended gap setting for this probe?

-

The recommended gap setting for radial vibration measurements is -9 Vdc, which is approximately 1.27 mm (50 mils).

-

-

What is the maximum shaft diameter for this system?

-

The recommended minimum shaft diameter is 50.8 mm (2 inches), with a preferred diameter of 76.2 mm (3 inches).

-

-

Can this system be used for overspeed protection?

-

Yes, it is suitable for overspeed protection applications when paired with the 3300 Proximitor sensor.

-

-

What is the cable type used with this probe?

-

The system uses a 75Ω triaxial cable, with options for armored or FluidLoc cable configurations.

-

-

How do I install the probe?

-

The probe features a standard 3/8-24 UNF thread or M10 x 1 thread, with recommended torque values provided for installation.

-

-

Is the system compatible with older 3300 series components?

-

Yes, the 3300 XL system is backward compatible with older non-XL 3300 series 5 mm and 8 mm probes and components.

-

-

Can I use the probe in hazardous areas?

-

Yes, it has certifications for use in hazardous areas, including ATEX, IECEx, and Class I, Zone 0 areas.

-

-

What is the weight of the entire system?

-

The total system weight is approximately 0.7 kg (1.5 lbs), with the probe alone weighing 323 g (11.4 oz).

-

-

What is the significance of the ClickLoc connectors?

-

The ClickLoc connectors provide a secure, tool-free connection, ensuring fast and reliable installations.

Bently Nevada 330101-00-16-10-02-00 3300 XL 8 mm Probe

Manufacturer:Bently Nevada

Product Number:330101-00-16-10-02-

Product Type:3300 XL 8 mm Probe

Origin:USA

Dimensions:1.0 meter

Weight:0.323 kg

Views:92

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300 XL 8 mm Probe is a key component in the 3300 XL Proximity Transducer System, designed for high-precision vibration and position measurement applications. This system is primarily used in fluid-film bearing machines and provides accurate, real-time data for vibration and position monitoring. The 3300 XL system includes the 8 mm probe, extension cables, and a Proximitor sensor, all of which are fully interchangeable and backward-compatible with non-XL 3300 components.

Product Specifications

| Specification | Details |

|---|---|

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Tip Material | Polyphenylene sulfide (PPS) |

| Probe Case Material | AISI 303 or 304 stainless steel (SST) |

| Electrical Input | Accepts one non-contacting 3300-series 5 mm, 3300 XL 8 mm probe |

| Power Requirements | -17.5 Vdc to -26 Vdc with a maximum 12 mA consumption |

| Nominal Probe DC Resistance | 7.59 ± 0.50 Ω at 1 meter length |

| Linear Range | 2 mm (80 mils) |

| Recommended Gap Setting | -9 Vdc (approximately 1.27 mm or 50 mils) |

| Connector Material | Gold-plated brass or gold-plated beryllium copper |

| Extension Cable Length | Available in lengths from 0.5 meters to 9 meters |

| Temperature Range (Probe) | -52°C to +177°C (-62°F to +350°F) |

| Temperature Range (Cable) | -52°C to +177°C (-62°F to +350°F) |

| Environmental Humidity | Less than 3% change in average scale factor (ASF) at 93% humidity |

Product Applications

The 3300 XL 8 mm Probe is used in a variety of industrial settings where precise vibration and position monitoring is necessary. Key applications include:

-

Vibration Monitoring: For detecting the condition of machines operating with fluid-film bearings.

-

Position Monitoring: Accurate measurement of position for rotating equipment.

-

Keyphasor Reference & Speed Measurement: Used in overspeed protection and speed measurement systems.

-

API 670 Compliance: Meets API 670 standards for mechanical configuration, range, and accuracy.

Product Advantages

-

High Precision: Delivers accurate vibration and position measurements, improving machine reliability.

-

Robust Design: The 8 mm probe has a robust, rugged design that can withstand harsh industrial environments.

-

Interchangeability: Fully compatible with both 3300 XL and non-XL components.

-

Enhanced RFI/EMI Immunity: The Proximitor sensor has improved immunity to electromagnetic and radio frequency interference, ensuring reliability in diverse environments.

-

Flexibility in Installation: The components offer flexibility in mounting configurations, including DIN-rail and panel mounts.

-

Low Maintenance: The ClickLoc connectors and enhanced design eliminate the need for frequent recalibration or component matching.

-

Extended Temperature Range: Available with an extended temperature range for use in high-heat environments (up to 425°F for probes).

FAQ

-

What is the maximum operating temperature of the Bently Nevada 3300 XL 8 mm Probe?

-

The standard probe can operate from -52°C to +177°C, and an extended range probe can operate up to +218°C for the probe tip and +260°C for the cable.

-

-

What is the recommended gap setting for this probe?

-

The recommended gap setting for radial vibration measurements is -9 Vdc, which is approximately 1.27 mm (50 mils).

-

-

What is the maximum shaft diameter for this system?

-

The recommended minimum shaft diameter is 50.8 mm (2 inches), with a preferred diameter of 76.2 mm (3 inches).

-

-

Can this system be used for overspeed protection?

-

Yes, it is suitable for overspeed protection applications when paired with the 3300 Proximitor sensor.

-

-

What is the cable type used with this probe?

-

The system uses a 75Ω triaxial cable, with options for armored or FluidLoc cable configurations.

-

-

How do I install the probe?

-

The probe features a standard 3/8-24 UNF thread or M10 x 1 thread, with recommended torque values provided for installation.

-

-

Is the system compatible with older 3300 series components?

-

Yes, the 3300 XL system is backward compatible with older non-XL 3300 series 5 mm and 8 mm probes and components.

-

-

Can I use the probe in hazardous areas?

-

Yes, it has certifications for use in hazardous areas, including ATEX, IECEx, and Class I, Zone 0 areas.

-

-

What is the weight of the entire system?

-

The total system weight is approximately 0.7 kg (1.5 lbs), with the probe alone weighing 323 g (11.4 oz).

-

-

What is the significance of the ClickLoc connectors?

-

The ClickLoc connectors provide a secure, tool-free connection, ensuring fast and reliable installations.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...