Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

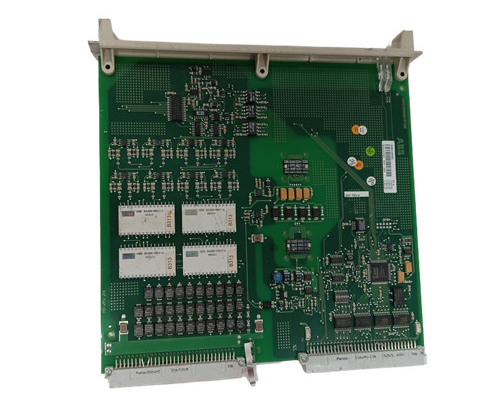

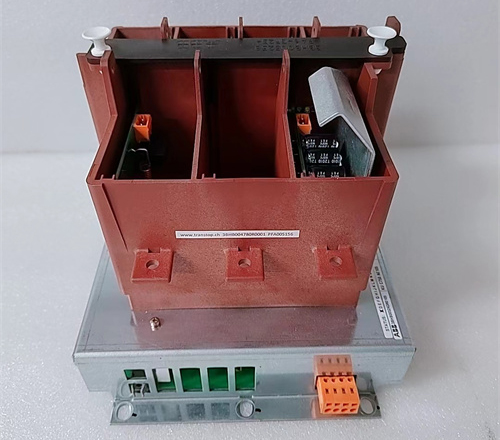

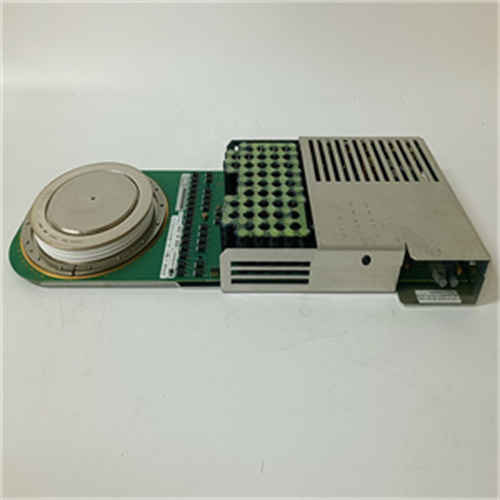

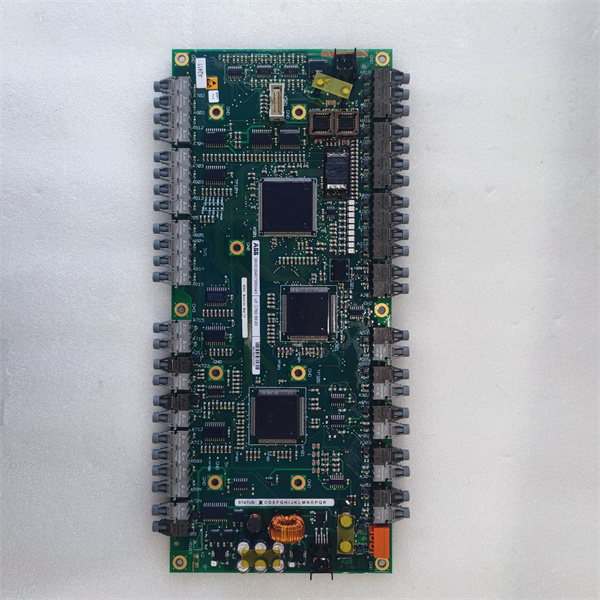

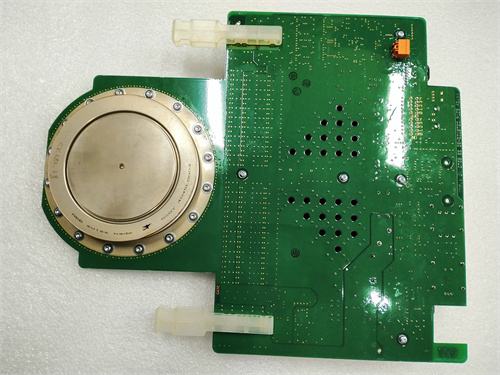

ABB PFXA401 3BSE024388R1 Control Unit

Manufacturer:ABB

Product Number:PFXA401 3BSE024388R1

Product Type:Control Unit

Origin:Sweden

Dimensions:124 x 124 x 119 mm

Weight:5 kg

Views:28

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PFXA401 3BSE024388R1 is a high-performance control unit that forms part of ABB’s renowned Symphony Plus and Advant OCS control families. Designed to function as a central control node in process automation environments, this module coordinates I/O processing, real-time logic execution, and system communication, ensuring precise and reliable process control in mission-critical industries.

As a modular and scalable solution, the PFXA401 is often deployed in power generation, petrochemical, and water treatment facilities where long-term reliability, system flexibility, and compatibility with ABB’s field-proven control platforms are required. Its architecture supports distributed control strategies, redundancy, and seamless integration with fieldbus and Ethernet-based communication networks.

The PFXA401 is widely regarded for its high availability, rugged design, and robust processing capability, enabling uninterrupted automation in complex systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | PFXA401 |

| Part Number | 3BSE024388R1 |

| Product Type | Control Unit / Controller Module |

| Manufacturer | ABB |

| Series | Symphony Plus / Advant OCS |

| Function | Central processing and control logic execution |

| Processor Type | High-speed industrial-grade processor |

| Memory | Integrated DRAM and flash memory |

| Operating System | Real-time embedded OS (ABB proprietary) |

| Communication Ports | Ethernet, Serial (RS-232/485), Control Network Interface |

| Protocols Supported | MODBUS TCP, PROFIBUS, IEC 61850, ABB Control Network |

| Redundancy | Fully supports CPU redundancy and hot-standby configurations |

| Operating Temperature | -20°C to +70°C (-4°F to +158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity Tolerance | 5% to 95% non-condensing |

| Power Supply | 24 VDC (typical range 18–32 VDC) |

| Mounting Method | Rack-mounted / DIN rail (depending on cabinet configuration) |

| Dimensions | 124 x 124 x 119 mm |

| Weight | 5 kg |

| Compliance Standards | CE, UL, RoHS, CSA, IEC 61131, EN 61010-1 |

| Hot-Swappable | Yes (when part of a redundant system with standby mode) |

| Firmware Upgrade | Supported via control engineering tools (e.g., Composer, Control Builder) |

Applications

The PFXA401 Control Unit is deployed across a wide spectrum of automation sectors, particularly where centralized, fault-tolerant, and deterministic control is required:

-

Power Generation (Thermal, Hydro, Renewables)

Acts as the core logic processor for turbine control, boiler control, generator excitation, and load dispatch.

-

Petrochemical and Refining Industries

Manages real-time process automation and emergency shutdown systems (ESD) with tight response times.

-

Water and Wastewater Treatment Plants

Controls pump stations, chemical dosing, filtration cycles, and data logging for regulatory compliance.

-

Paper and Pulp Industry

Handles complex batch processing, dryer section control, and supervisory operations.

-

Pharmaceutical Manufacturing

Ensures compliance with cGMP standards while managing recipe-based and sequential batch control.

-

Cement and Building Materials

Coordinates critical process steps such as kilning, grinding, and packing operations.

Product Advantages

-

High-Speed Processing

Executes control logic and PID loops with minimal latency, ideal for real-time automation.

-

Redundancy and Fault Tolerance

Supports hot-standby CPU redundancy, ensuring zero process downtime in case of failure.

-

Modular Integration

Easily connects with ABB’s I/O modules, HMI systems, and third-party field devices using open protocols.

-

Robust Environmental Endurance

Designed to withstand high temperature, humidity, and electrical noise conditions.

-

Secure Firmware & Network Communication

Features secure boot processes and encrypted communication to prevent unauthorized access.

-

Seamless Engineering Toolchain

Configurable via ABB’s Composer or Control Builder software, reducing commissioning effort.

-

Flexible Communication Interfaces

Offers multiple serial and Ethernet ports for system-wide connectivity.

-

Long-Term Availability

Backed by ABB’s long product life cycles and global support infrastructure.

Frequently Asked Questions (FAQ)

-

What is the role of the PFXA401 in an automation system?

It functions as the main controller, executing logic and managing communication across I/O modules and networks.

-

Is the PFXA401 compatible with ABB Symphony Plus systems?

Yes, it is designed specifically for integration with Symphony Plus and Advant OCS platforms.

-

Does the PFXA401 support redundancy?

Yes, it supports CPU redundancy and can be configured in hot-standby mode for high availability.

-

What protocols are supported for third-party device integration?

It supports MODBUS TCP, PROFIBUS, IEC 61850, and ABB Control Network protocols.

-

Can the unit be replaced without shutting down the system?

In redundant systems, the PFXA401 can be replaced while the standby unit maintains control (hot-swappable).

-

How is the unit configured and maintained?

Configuration and firmware updates are performed using ABB’s Composer or Control Builder software tools.

-

Is the PFXA401 suitable for outdoor environments?

While rugged, it must be housed in an industrial enclosure or cabinet with proper environmental protection.

-

What is the typical lifespan of this module?

With proper maintenance, the unit offers a long operational life exceeding 10 years under industrial use.

-

What happens if communication is lost with connected I/O modules?

The system can be configured to enter safe fallback states or trigger alarms on communication loss.

-

Can it be used in safety instrumented systems (SIS)?

When combined with certified safety I/O modules, it can contribute to certain SIL-rated architectures.

ABB PFXA401 3BSE024388R1 Control Unit

Manufacturer:ABB

Product Number:PFXA401 3BSE024388R1

Product Type:Control Unit

Origin:Sweden

Dimensions:124 x 124 x 119 mm

Weight:5 kg

Views:28

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PFXA401 3BSE024388R1 is a high-performance control unit that forms part of ABB’s renowned Symphony Plus and Advant OCS control families. Designed to function as a central control node in process automation environments, this module coordinates I/O processing, real-time logic execution, and system communication, ensuring precise and reliable process control in mission-critical industries.

As a modular and scalable solution, the PFXA401 is often deployed in power generation, petrochemical, and water treatment facilities where long-term reliability, system flexibility, and compatibility with ABB’s field-proven control platforms are required. Its architecture supports distributed control strategies, redundancy, and seamless integration with fieldbus and Ethernet-based communication networks.

The PFXA401 is widely regarded for its high availability, rugged design, and robust processing capability, enabling uninterrupted automation in complex systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | PFXA401 |

| Part Number | 3BSE024388R1 |

| Product Type | Control Unit / Controller Module |

| Manufacturer | ABB |

| Series | Symphony Plus / Advant OCS |

| Function | Central processing and control logic execution |

| Processor Type | High-speed industrial-grade processor |

| Memory | Integrated DRAM and flash memory |

| Operating System | Real-time embedded OS (ABB proprietary) |

| Communication Ports | Ethernet, Serial (RS-232/485), Control Network Interface |

| Protocols Supported | MODBUS TCP, PROFIBUS, IEC 61850, ABB Control Network |

| Redundancy | Fully supports CPU redundancy and hot-standby configurations |

| Operating Temperature | -20°C to +70°C (-4°F to +158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity Tolerance | 5% to 95% non-condensing |

| Power Supply | 24 VDC (typical range 18–32 VDC) |

| Mounting Method | Rack-mounted / DIN rail (depending on cabinet configuration) |

| Dimensions | 124 x 124 x 119 mm |

| Weight | 5 kg |

| Compliance Standards | CE, UL, RoHS, CSA, IEC 61131, EN 61010-1 |

| Hot-Swappable | Yes (when part of a redundant system with standby mode) |

| Firmware Upgrade | Supported via control engineering tools (e.g., Composer, Control Builder) |

Applications

The PFXA401 Control Unit is deployed across a wide spectrum of automation sectors, particularly where centralized, fault-tolerant, and deterministic control is required:

-

Power Generation (Thermal, Hydro, Renewables)

Acts as the core logic processor for turbine control, boiler control, generator excitation, and load dispatch.

-

Petrochemical and Refining Industries

Manages real-time process automation and emergency shutdown systems (ESD) with tight response times.

-

Water and Wastewater Treatment Plants

Controls pump stations, chemical dosing, filtration cycles, and data logging for regulatory compliance.

-

Paper and Pulp Industry

Handles complex batch processing, dryer section control, and supervisory operations.

-

Pharmaceutical Manufacturing

Ensures compliance with cGMP standards while managing recipe-based and sequential batch control.

-

Cement and Building Materials

Coordinates critical process steps such as kilning, grinding, and packing operations.

Product Advantages

-

High-Speed Processing

Executes control logic and PID loops with minimal latency, ideal for real-time automation.

-

Redundancy and Fault Tolerance

Supports hot-standby CPU redundancy, ensuring zero process downtime in case of failure.

-

Modular Integration

Easily connects with ABB’s I/O modules, HMI systems, and third-party field devices using open protocols.

-

Robust Environmental Endurance

Designed to withstand high temperature, humidity, and electrical noise conditions.

-

Secure Firmware & Network Communication

Features secure boot processes and encrypted communication to prevent unauthorized access.

-

Seamless Engineering Toolchain

Configurable via ABB’s Composer or Control Builder software, reducing commissioning effort.

-

Flexible Communication Interfaces

Offers multiple serial and Ethernet ports for system-wide connectivity.

-

Long-Term Availability

Backed by ABB’s long product life cycles and global support infrastructure.

Frequently Asked Questions (FAQ)

-

What is the role of the PFXA401 in an automation system?

It functions as the main controller, executing logic and managing communication across I/O modules and networks.

-

Is the PFXA401 compatible with ABB Symphony Plus systems?

Yes, it is designed specifically for integration with Symphony Plus and Advant OCS platforms.

-

Does the PFXA401 support redundancy?

Yes, it supports CPU redundancy and can be configured in hot-standby mode for high availability.

-

What protocols are supported for third-party device integration?

It supports MODBUS TCP, PROFIBUS, IEC 61850, and ABB Control Network protocols.

-

Can the unit be replaced without shutting down the system?

In redundant systems, the PFXA401 can be replaced while the standby unit maintains control (hot-swappable).

-

How is the unit configured and maintained?

Configuration and firmware updates are performed using ABB’s Composer or Control Builder software tools.

-

Is the PFXA401 suitable for outdoor environments?

While rugged, it must be housed in an industrial enclosure or cabinet with proper environmental protection.

-

What is the typical lifespan of this module?

With proper maintenance, the unit offers a long operational life exceeding 10 years under industrial use.

-

What happens if communication is lost with connected I/O modules?

The system can be configured to enter safe fallback states or trigger alarms on communication loss.

-

Can it be used in safety instrumented systems (SIS)?

When combined with certified safety I/O modules, it can contribute to certain SIL-rated architectures.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...