Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

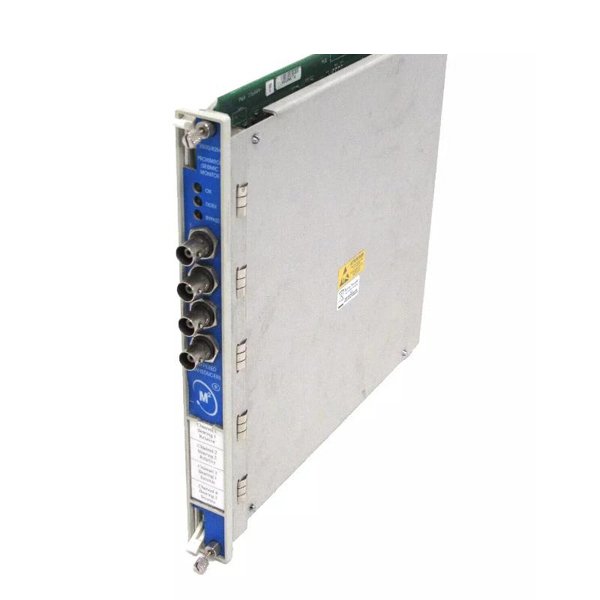

Bently Nevada 3500/42M-01-00 176449-02 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42M-01-00 176449-02

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42M Proximitor Seismic Monitor is a four-channel module designed to monitor vibration, position, and seismic parameters in critical rotating machinery. It continuously compares measured parameters with programmable alarm thresholds to protect equipment and notify personnel of abnormal conditions. Each channel pair can be programmed independently to perform different monitoring functions simultaneously.

Product Features and Advantages

-

Supports proximity and seismic transducers for versatile monitoring

-

Multiple measurement modes including radial vibration, thrust, acceleration, eccentricity, and more

-

User-programmable alarm setpoints with high accuracy

-

Fast update rates and buffered outputs for real-time data

-

Robust design suitable for harsh industrial environments

Applications

-

Turbomachinery vibration monitoring

-

Shaft position and displacement measurement

-

Thrust bearing wear detection

-

Seismic and structural vibration monitoring

-

Rotating machinery health diagnostics in power plants, refineries, and offshore platforms

Technical Specifications

| Parameter | Specification |

|---|---|

| Input Channels | 4 channels (proximity, velocity, or acceleration transducers) |

| Power Consumption | 7.7 W typical |

| Sensitivity | Radial Vibration: 3.94 mV/μm or 7.87 mV/μm |

| Frequency Response | Up to 30,000 Hz (depending on mode) |

| Alarm Accuracy | Within ±0.13% |

| Operating Temperature | -30°C to +65°C |

| Dimensions (H x W x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Compliance | FCC, CE, RoHS, ABS, DNV GL |

| Hazardous Area Approvals | Class I Div 2, ATEX, IECEx |

FAQ

Q1: What types of transducers can the 3500/42M monitor?

A1: It supports proximity probes, velocity pickups, and accelerometers.

Q2: Can each channel monitor different parameters?

A2: Yes, channels are programmable in pairs to monitor different or identical parameters.

Q3: What is the update rate of the output signals?

A3: The monitor updates approximately every 100 milliseconds.

Q4: Does it provide buffered transducer outputs?

A4: Yes, each channel has a buffered output for direct transducer signal access.

Q5: What is the operating temperature range?

A5: It operates between -30°C and +65°C.

Q6: How accurate are the alarm setpoints?

A6: Alarm setpoints are accurate within ±0.13% of the desired value.

Q7: What certifications does the device carry?

A7: It complies with FCC, CE, RoHS, and carries marine and hazardous area certifications.

Q8: Can it be used in hazardous environments?

A8: Yes, it is certified for Class I Division 2 and ATEX/IECEx Zone 2.

Q9: How is configuration performed?

A9: Using the Bently Nevada 3500 Rack Configuration Software.

Q10: What is the typical application of this monitor?

A10: Protection and condition monitoring of critical rotating machinery like turbines, compressors, and pumps.

Bently Nevada 3500/42M-01-00 176449-02 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42M-01-00 176449-02

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42M Proximitor Seismic Monitor is a four-channel module designed to monitor vibration, position, and seismic parameters in critical rotating machinery. It continuously compares measured parameters with programmable alarm thresholds to protect equipment and notify personnel of abnormal conditions. Each channel pair can be programmed independently to perform different monitoring functions simultaneously.

Product Features and Advantages

-

Supports proximity and seismic transducers for versatile monitoring

-

Multiple measurement modes including radial vibration, thrust, acceleration, eccentricity, and more

-

User-programmable alarm setpoints with high accuracy

-

Fast update rates and buffered outputs for real-time data

-

Robust design suitable for harsh industrial environments

Applications

-

Turbomachinery vibration monitoring

-

Shaft position and displacement measurement

-

Thrust bearing wear detection

-

Seismic and structural vibration monitoring

-

Rotating machinery health diagnostics in power plants, refineries, and offshore platforms

Technical Specifications

| Parameter | Specification |

|---|---|

| Input Channels | 4 channels (proximity, velocity, or acceleration transducers) |

| Power Consumption | 7.7 W typical |

| Sensitivity | Radial Vibration: 3.94 mV/μm or 7.87 mV/μm |

| Frequency Response | Up to 30,000 Hz (depending on mode) |

| Alarm Accuracy | Within ±0.13% |

| Operating Temperature | -30°C to +65°C |

| Dimensions (H x W x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Compliance | FCC, CE, RoHS, ABS, DNV GL |

| Hazardous Area Approvals | Class I Div 2, ATEX, IECEx |

FAQ

Q1: What types of transducers can the 3500/42M monitor?

A1: It supports proximity probes, velocity pickups, and accelerometers.

Q2: Can each channel monitor different parameters?

A2: Yes, channels are programmable in pairs to monitor different or identical parameters.

Q3: What is the update rate of the output signals?

A3: The monitor updates approximately every 100 milliseconds.

Q4: Does it provide buffered transducer outputs?

A4: Yes, each channel has a buffered output for direct transducer signal access.

Q5: What is the operating temperature range?

A5: It operates between -30°C and +65°C.

Q6: How accurate are the alarm setpoints?

A6: Alarm setpoints are accurate within ±0.13% of the desired value.

Q7: What certifications does the device carry?

A7: It complies with FCC, CE, RoHS, and carries marine and hazardous area certifications.

Q8: Can it be used in hazardous environments?

A8: Yes, it is certified for Class I Division 2 and ATEX/IECEx Zone 2.

Q9: How is configuration performed?

A9: Using the Bently Nevada 3500 Rack Configuration Software.

Q10: What is the typical application of this monitor?

A10: Protection and condition monitoring of critical rotating machinery like turbines, compressors, and pumps.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...