Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

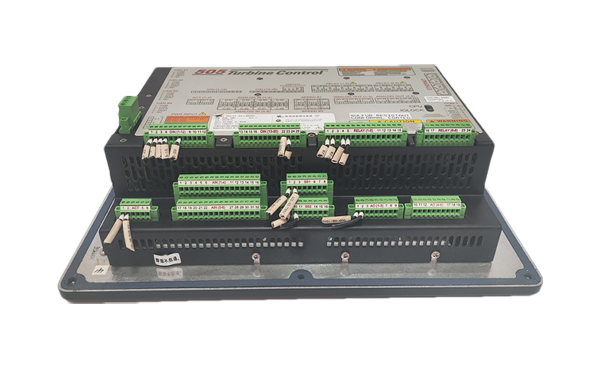

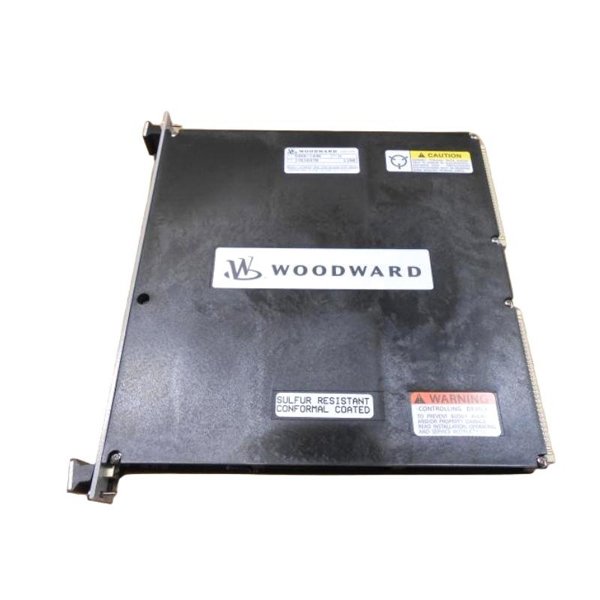

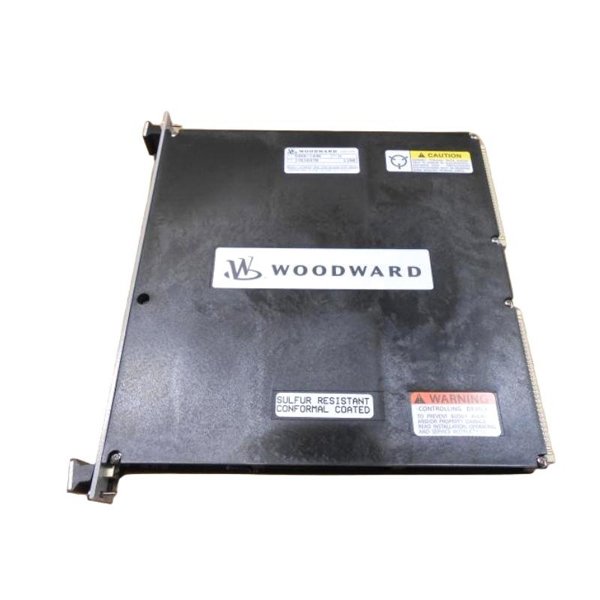

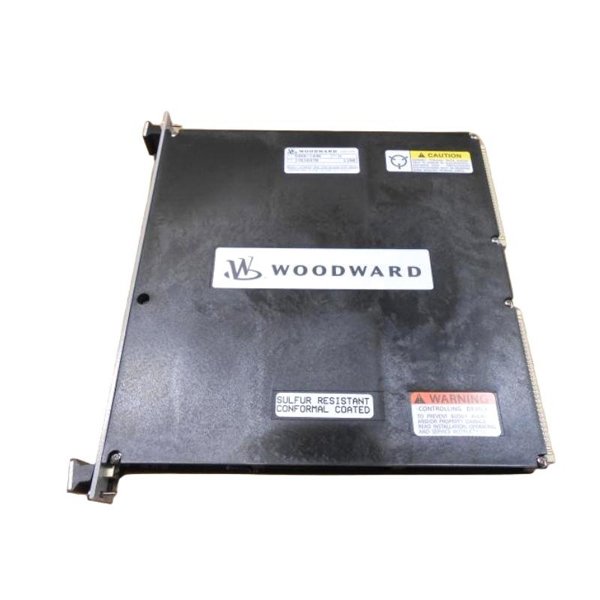

Woodward 5464-211 Integrating Act Driver Module

Manufacturer:Woodward

Product Number:5464-211

Product Type:Integrating Act Driver Module

Origin:USA

Dimensions:26 x 248 x 262 mm

Weight:1.08 kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 5464-211 Integrating Act Driver Module is a key component in Woodward’s control system architecture, specifically designed to drive and manage actuators in industrial automation systems. This module functions as an intermediary between the control system and physical actuators, enabling precise movement and integration of control signals into mechanical motion.

With its high level of responsiveness and stability, the 5464-211 module is ideal for mission-critical applications where the coordination between control signals and actuator output is essential. As part of the Woodward MicroNet and Atlas control platforms, it plays a significant role in turbine control, power generation systems, and large-scale industrial process management.

This model is engineered to integrate smoothly with other Woodward I/O and control hardware, offering flexible mounting, intuitive configuration, and robust diagnostics—all wrapped in a compact, durable form factor.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 5464-211 |

| Product Type | Integrating Actuator Driver Module |

| Manufacturer | Woodward |

| Series | MicroNet / Atlas Series |

| Function | Drives and manages actuator signals |

| Control Interface | Analog or digital, system-configurable |

| Input Voltage | 24V DC nominal |

| Output Signal | 4–20 mA, ±10 VDC (depending on configuration) |

| Communication Protocols | Compatible with Woodward’s proprietary control buses |

| Actuator Types Supported | Hydraulic, pneumatic, electric actuators |

| LED Indicators | Status, error, signal activity |

| Mounting Type | DIN rail or panel mount |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5%–95% RH, non-condensing |

| Certifications | CE, UL, CSA, RoHS |

| Dimensions | 26 x 248 x 262 mm |

| Weight | 1.08 kg |

Product Applications

The 5464-211 Integrating Act Driver Module is employed across various industries where precision actuator control is essential. Typical applications include:

-

Gas and Steam Turbines: For managing valve positions and load control.

-

Power Generation Plants: Governs actuators involved in speed and fuel control loops.

-

Marine and Offshore Systems: Ensures safe operation of propulsion and auxiliary systems.

-

Oil and Gas Processing: Controls actuators in separation units, compressors, and pumps.

-

Industrial Automation: Integrated into robotic arms, CNC machinery, and material handling systems.

-

Renewable Energy Systems: Used in wind turbine blade pitch control or solar tracking.

Product Advantages

-

Precise Integration: Offers high-resolution control signals for accurate actuator response.

-

Stable and Reliable: Designed for uninterrupted operation under demanding industrial conditions.

-

Flexible Output: Supports both voltage and current signal outputs, adapting to a variety of actuators.

-

Seamless System Compatibility: Easily integrates with Woodward’s MicroNet and Atlas control systems.

-

Real-Time Diagnostics: LED indicators and fault monitoring improve system maintainability.

-

Rugged Design: Engineered to withstand vibration, thermal variation, and harsh environments.

-

Low Maintenance: Durable build with minimal service needs over long operational periods.

Frequently Asked Questions (FAQ)

-

What is the function of the 5464-211 Integrating Act Driver Module?

It translates control system commands into signals that drive actuators in industrial systems.

-

Is the module compatible with both analog and digital actuators?

Yes, it supports a wide range of actuator types, including analog-controlled and digitally interfaced ones.

-

Does it support remote diagnostics?

While it does not have native remote diagnostics, it integrates with control systems that do.

-

What voltage does it operate on?

The standard operating voltage is 24V DC.

-

Can it be hot-swapped?

Hot-swapping depends on the control system design, but it’s generally recommended to power down first.

-

What types of systems is it used in?

Primarily in turbine control systems, generator sets, and other critical motion-control applications.

-

Is firmware updating supported?

Firmware updates are typically managed through the host control system, not directly on the module.

-

How is the module mounted?

It can be installed on a DIN rail or panel-mounted in a control cabinet.

-

Are there LED indicators on the module?

Yes, the module includes LED indicators for signal activity, operational status, and error conditions.

-

How often does the module need maintenance?

Under normal conditions, it requires little to no routine maintenance beyond periodic system checks.

Woodward 5464-211 Integrating Act Driver Module

Manufacturer:Woodward

Product Number:5464-211

Product Type:Integrating Act Driver Module

Origin:USA

Dimensions:26 x 248 x 262 mm

Weight:1.08 kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 5464-211 Integrating Act Driver Module is a key component in Woodward’s control system architecture, specifically designed to drive and manage actuators in industrial automation systems. This module functions as an intermediary between the control system and physical actuators, enabling precise movement and integration of control signals into mechanical motion.

With its high level of responsiveness and stability, the 5464-211 module is ideal for mission-critical applications where the coordination between control signals and actuator output is essential. As part of the Woodward MicroNet and Atlas control platforms, it plays a significant role in turbine control, power generation systems, and large-scale industrial process management.

This model is engineered to integrate smoothly with other Woodward I/O and control hardware, offering flexible mounting, intuitive configuration, and robust diagnostics—all wrapped in a compact, durable form factor.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 5464-211 |

| Product Type | Integrating Actuator Driver Module |

| Manufacturer | Woodward |

| Series | MicroNet / Atlas Series |

| Function | Drives and manages actuator signals |

| Control Interface | Analog or digital, system-configurable |

| Input Voltage | 24V DC nominal |

| Output Signal | 4–20 mA, ±10 VDC (depending on configuration) |

| Communication Protocols | Compatible with Woodward’s proprietary control buses |

| Actuator Types Supported | Hydraulic, pneumatic, electric actuators |

| LED Indicators | Status, error, signal activity |

| Mounting Type | DIN rail or panel mount |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5%–95% RH, non-condensing |

| Certifications | CE, UL, CSA, RoHS |

| Dimensions | 26 x 248 x 262 mm |

| Weight | 1.08 kg |

Product Applications

The 5464-211 Integrating Act Driver Module is employed across various industries where precision actuator control is essential. Typical applications include:

-

Gas and Steam Turbines: For managing valve positions and load control.

-

Power Generation Plants: Governs actuators involved in speed and fuel control loops.

-

Marine and Offshore Systems: Ensures safe operation of propulsion and auxiliary systems.

-

Oil and Gas Processing: Controls actuators in separation units, compressors, and pumps.

-

Industrial Automation: Integrated into robotic arms, CNC machinery, and material handling systems.

-

Renewable Energy Systems: Used in wind turbine blade pitch control or solar tracking.

Product Advantages

-

Precise Integration: Offers high-resolution control signals for accurate actuator response.

-

Stable and Reliable: Designed for uninterrupted operation under demanding industrial conditions.

-

Flexible Output: Supports both voltage and current signal outputs, adapting to a variety of actuators.

-

Seamless System Compatibility: Easily integrates with Woodward’s MicroNet and Atlas control systems.

-

Real-Time Diagnostics: LED indicators and fault monitoring improve system maintainability.

-

Rugged Design: Engineered to withstand vibration, thermal variation, and harsh environments.

-

Low Maintenance: Durable build with minimal service needs over long operational periods.

Frequently Asked Questions (FAQ)

-

What is the function of the 5464-211 Integrating Act Driver Module?

It translates control system commands into signals that drive actuators in industrial systems.

-

Is the module compatible with both analog and digital actuators?

Yes, it supports a wide range of actuator types, including analog-controlled and digitally interfaced ones.

-

Does it support remote diagnostics?

While it does not have native remote diagnostics, it integrates with control systems that do.

-

What voltage does it operate on?

The standard operating voltage is 24V DC.

-

Can it be hot-swapped?

Hot-swapping depends on the control system design, but it’s generally recommended to power down first.

-

What types of systems is it used in?

Primarily in turbine control systems, generator sets, and other critical motion-control applications.

-

Is firmware updating supported?

Firmware updates are typically managed through the host control system, not directly on the module.

-

How is the module mounted?

It can be installed on a DIN rail or panel-mounted in a control cabinet.

-

Are there LED indicators on the module?

Yes, the module includes LED indicators for signal activity, operational status, and error conditions.

-

How often does the module need maintenance?

Under normal conditions, it requires little to no routine maintenance beyond periodic system checks.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...