Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

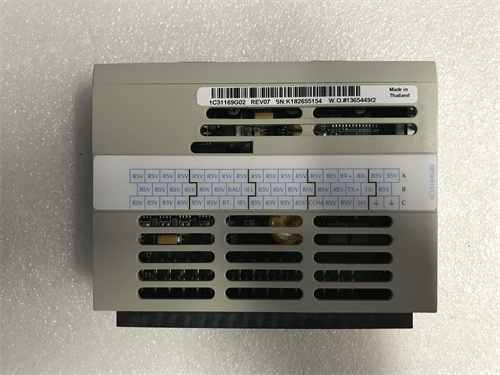

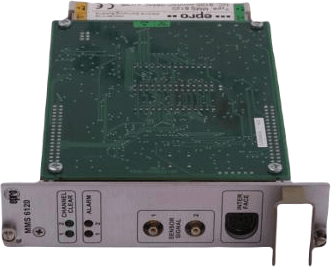

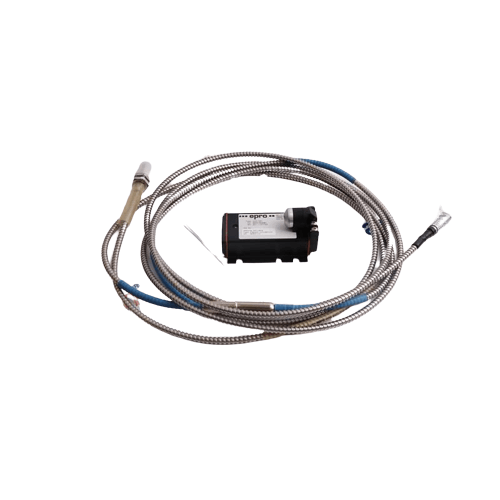

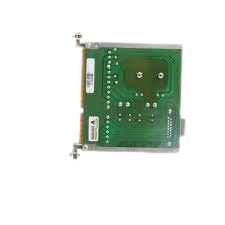

Emerson KJ2006X1-BK2 SE4026 Virtual I/O Module

Manufacturer:Emerson

Product Number:KJ2006X1-BK2 SE4026

Product Type:Virtual I/O Module

Origin:USA

Dimensions:42 x 199 x 162 mm

Weight:0.5 kg

Views:90

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson KJ2006X1-BK2 SE4026 Virtual I/O Module is a key component of Emerson’s DeltaV™ control system, designed to provide flexibility in system configuration by allowing the virtualization of I/O subsystems. This module enables integration of process simulation, controller testing, and virtual commissioning without the need for physical I/O wiring. As part of the SE4026 Virtual I/O series, it facilitates seamless interaction with emulated field devices or soft controllers, making it a valuable tool for both system development and operational environments.

This module supports multiple communication protocols, offers high-speed data transfer, and is fully compatible with existing DeltaV infrastructure. It is ideal for simulation, training, and testing applications, where replicating real I/O behavior is essential without the associated hardware costs or complexity.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | KJ2006X1-BK2 |

| Series | SE4026 |

| Module Type | Virtual I/O Module |

| System Platform | DeltaV™ DCS |

| Emulation Type | Virtual Analog and Digital I/O |

| Communication Protocols | OPC, Modbus TCP/IP, DeltaV Virtual I/O Bus |

| Data Rate | 100 Mbps Ethernet |

| Controller Compatibility | DeltaV SE3000/SE4000 Series |

| Application Usage | Simulation, Testing, Virtual Commissioning |

| Software Integration | DeltaV Simulate, DeltaV Operate, Virtual Studio |

| Redundancy Support | No (Virtual-only module) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Power Supply | Powered via DeltaV System or Virtual Environment |

| Power Consumption | < 3 W |

| Mounting | Virtual deployment (no physical mounting required) |

| Dimensions (W x H x D) | 42 x 199 x 162 mm |

| Weight | 0.5 kg |

| Certifications | N/A (Virtual-only module) |

Product Applications

The KJ2006X1-BK2 SE4026 module is specifically designed for non-production environments, helping engineers, operators, and developers in the following areas:

-

Control System Simulation: Emulates real I/O behavior for controller testing and simulation.

-

Operator Training Systems (OTS): Used to simulate plant scenarios without live I/O.

-

Factory Acceptance Testing (FAT): Enables early validation of control logic prior to on-site installation.

-

Software-in-the-Loop (SIL): Integrates with DeltaV’s virtual studio for system development testing.

-

Process Commissioning: Reduces commissioning time by simulating full I/O behavior.

-

Disaster Recovery & System Backup: Supports virtual environments used for system recovery planning.

Product Advantages

-

Cost Efficiency: Eliminates the need for physical I/O hardware during simulation and testing.

-

Rapid Deployment: Easily deployable in virtual machines without wiring or hardware constraints.

-

Improved Testing Accuracy: Emulates actual I/O signals to ensure control strategies function correctly.

-

Enhanced Training Capabilities: Allows for real-world training experiences using virtual process models.

-

Flexible Configuration: Seamlessly integrates with DeltaV controllers and operator workstations.

-

Scalable Architecture: Expandable with additional virtual I/O instances to mirror plant-scale systems.

-

Time Saving: Accelerates FAT and commissioning by decoupling control logic testing from hardware.

-

Software Integration: Fully compatible with DeltaV Simulate and Virtual Studio environments.

-

No Physical Wear: Being virtual, there’s no degradation or mechanical failure over time.

-

Easy Backup and Replication: Simplifies replication of systems across multiple test environments.

FAQ

-

Does the SE4026 Virtual I/O module require physical installation?

No, it is deployed virtually and does not require physical mounting or wiring.

-

Which DeltaV systems are compatible with the KJ2006X1-BK2 module?

It is compatible with DeltaV SE3000 and SE4000 series controllers and simulation environments.

-

Can this module be used in live plant operations?

No, it is intended strictly for simulation, training, and development—not for live process control.

-

What protocols does it support for data exchange?

It supports OPC, Modbus TCP/IP, and DeltaV Virtual I/O bus communication.

-

How many virtual channels can be configured per module?

Up to 64 I/O channels can be emulated, including analog input/output and digital input/output.

-

Is the module capable of simulating failover or I/O errors?

Yes, simulated faults and diagnostic scenarios can be configured for training or testing.

-

Can this virtual module work with third-party PLC simulators?

Yes, through OPC or Modbus interfaces, it can communicate with third-party simulation platforms.

-

How is the virtual module licensed and deployed?

It is licensed through Emerson’s DeltaV Simulate or Virtual Studio and deployed via virtual machines.

-

Is there redundancy support for this module?

No, redundancy is not applicable as it is a non-hardware component within a virtual setup.

-

Can it be used alongside physical I/O in a hybrid simulation setup?

Yes, virtual and physical I/O modules can coexist in the DeltaV simulation architecture.

Emerson KJ2006X1-BK2 SE4026 Virtual I/O Module

Manufacturer:Emerson

Product Number:KJ2006X1-BK2 SE4026

Product Type:Virtual I/O Module

Origin:USA

Dimensions:42 x 199 x 162 mm

Weight:0.5 kg

Views:90

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson KJ2006X1-BK2 SE4026 Virtual I/O Module is a key component of Emerson’s DeltaV™ control system, designed to provide flexibility in system configuration by allowing the virtualization of I/O subsystems. This module enables integration of process simulation, controller testing, and virtual commissioning without the need for physical I/O wiring. As part of the SE4026 Virtual I/O series, it facilitates seamless interaction with emulated field devices or soft controllers, making it a valuable tool for both system development and operational environments.

This module supports multiple communication protocols, offers high-speed data transfer, and is fully compatible with existing DeltaV infrastructure. It is ideal for simulation, training, and testing applications, where replicating real I/O behavior is essential without the associated hardware costs or complexity.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | KJ2006X1-BK2 |

| Series | SE4026 |

| Module Type | Virtual I/O Module |

| System Platform | DeltaV™ DCS |

| Emulation Type | Virtual Analog and Digital I/O |

| Communication Protocols | OPC, Modbus TCP/IP, DeltaV Virtual I/O Bus |

| Data Rate | 100 Mbps Ethernet |

| Controller Compatibility | DeltaV SE3000/SE4000 Series |

| Application Usage | Simulation, Testing, Virtual Commissioning |

| Software Integration | DeltaV Simulate, DeltaV Operate, Virtual Studio |

| Redundancy Support | No (Virtual-only module) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Power Supply | Powered via DeltaV System or Virtual Environment |

| Power Consumption | < 3 W |

| Mounting | Virtual deployment (no physical mounting required) |

| Dimensions (W x H x D) | 42 x 199 x 162 mm |

| Weight | 0.5 kg |

| Certifications | N/A (Virtual-only module) |

Product Applications

The KJ2006X1-BK2 SE4026 module is specifically designed for non-production environments, helping engineers, operators, and developers in the following areas:

-

Control System Simulation: Emulates real I/O behavior for controller testing and simulation.

-

Operator Training Systems (OTS): Used to simulate plant scenarios without live I/O.

-

Factory Acceptance Testing (FAT): Enables early validation of control logic prior to on-site installation.

-

Software-in-the-Loop (SIL): Integrates with DeltaV’s virtual studio for system development testing.

-

Process Commissioning: Reduces commissioning time by simulating full I/O behavior.

-

Disaster Recovery & System Backup: Supports virtual environments used for system recovery planning.

Product Advantages

-

Cost Efficiency: Eliminates the need for physical I/O hardware during simulation and testing.

-

Rapid Deployment: Easily deployable in virtual machines without wiring or hardware constraints.

-

Improved Testing Accuracy: Emulates actual I/O signals to ensure control strategies function correctly.

-

Enhanced Training Capabilities: Allows for real-world training experiences using virtual process models.

-

Flexible Configuration: Seamlessly integrates with DeltaV controllers and operator workstations.

-

Scalable Architecture: Expandable with additional virtual I/O instances to mirror plant-scale systems.

-

Time Saving: Accelerates FAT and commissioning by decoupling control logic testing from hardware.

-

Software Integration: Fully compatible with DeltaV Simulate and Virtual Studio environments.

-

No Physical Wear: Being virtual, there’s no degradation or mechanical failure over time.

-

Easy Backup and Replication: Simplifies replication of systems across multiple test environments.

FAQ

-

Does the SE4026 Virtual I/O module require physical installation?

No, it is deployed virtually and does not require physical mounting or wiring.

-

Which DeltaV systems are compatible with the KJ2006X1-BK2 module?

It is compatible with DeltaV SE3000 and SE4000 series controllers and simulation environments.

-

Can this module be used in live plant operations?

No, it is intended strictly for simulation, training, and development—not for live process control.

-

What protocols does it support for data exchange?

It supports OPC, Modbus TCP/IP, and DeltaV Virtual I/O bus communication.

-

How many virtual channels can be configured per module?

Up to 64 I/O channels can be emulated, including analog input/output and digital input/output.

-

Is the module capable of simulating failover or I/O errors?

Yes, simulated faults and diagnostic scenarios can be configured for training or testing.

-

Can this virtual module work with third-party PLC simulators?

Yes, through OPC or Modbus interfaces, it can communicate with third-party simulation platforms.

-

How is the virtual module licensed and deployed?

It is licensed through Emerson’s DeltaV Simulate or Virtual Studio and deployed via virtual machines.

-

Is there redundancy support for this module?

No, redundancy is not applicable as it is a non-hardware component within a virtual setup.

-

Can it be used alongside physical I/O in a hybrid simulation setup?

Yes, virtual and physical I/O modules can coexist in the DeltaV simulation architecture.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...