Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

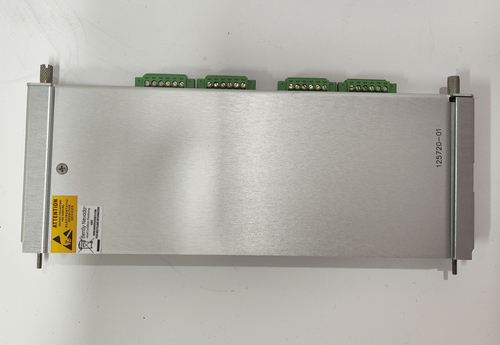

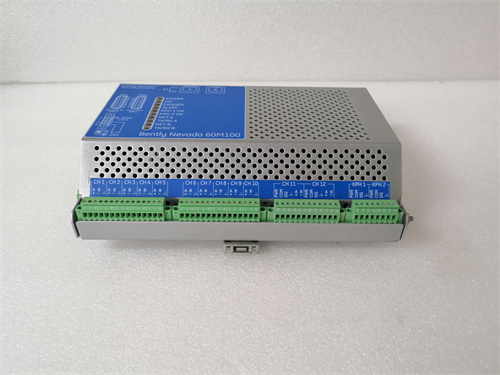

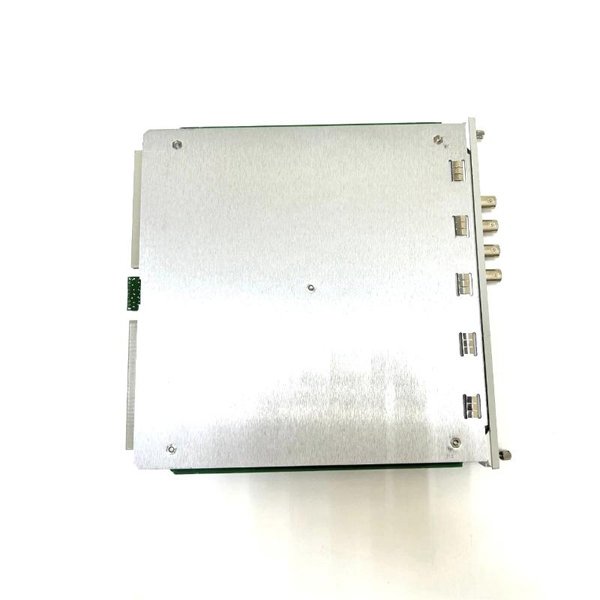

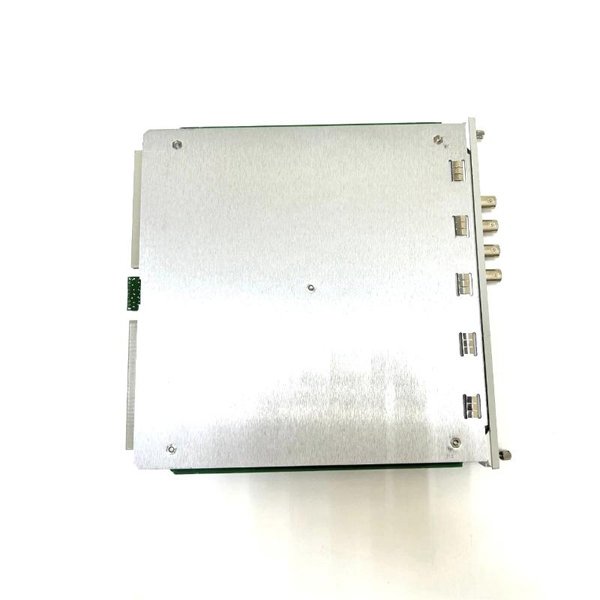

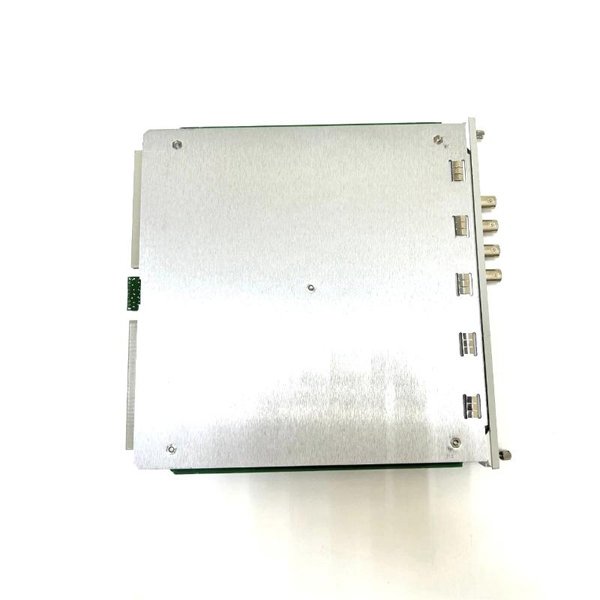

Bently Nevada 3500/42-04-02 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-04-02

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:31

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-04-02 is a high-performance monitoring module designed to measure and analyze vibration and seismic parameters in critical rotating machinery. It is part of the 3500 machinery protection system and offers real-time monitoring for both proximitor and seismic transducer inputs. This ensures early detection of mechanical issues, reducing unplanned downtime and preventing catastrophic equipment failures.

Product Specifications

| Parameter | Value |

|---|---|

| Module Type | Proximitor / Seismic Monitor |

| Channels | 2 (per module) |

| Input Types | Proximitor® or Seismic transducers |

| Signal Processing | True peak, RMS, 1X, 2X, gap measurements |

| Transducer Power Supply | Integrated |

| Communication | Through 3500 rack system |

| Dimensions (H × W × D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 Series rack |

| Operating Temperature | -30°C to +65°C |

| Certifications | CE, CSA, ATEX (varies with configuration) |

Applications

-

Steam Turbines – Detects imbalance, misalignment, and bearing faults.

-

Gas Turbines – Monitors casing vibrations and rotor displacement.

-

Compressors – Identifies early-stage faults such as surge-induced vibration.

-

Pumps – Ensures smooth operation by monitoring bearing wear and cavitation.

-

Gearboxes – Detects gear mesh defects and lubrication issues.

-

Industrial Fans – Monitors operational vibration for preventive maintenance.

Key Advantages

-

Dual Monitoring Capability – Supports both proximitor and seismic measurements.

-

Advanced Signal Processing – Accurate RMS and peak measurements for precise diagnostics.

-

High Reliability – Designed for continuous industrial operation in harsh environments.

-

Seamless Integration – Fully compatible with the 3500 Series machinery protection system.

-

Flexible Configuration – Allows user-defined alarm and trip settings.

-

Proven Field Performance – Trusted in critical rotating equipment worldwide.

FAQ

-

Q: What is the main function of the 3500/42-04-02?

A: To monitor vibration and seismic parameters for machinery protection.

-

Q: How many channels does the module support?

A: It supports 2 independent monitoring channels.

-

Q: Can it work with both proximitor and seismic transducers?

A: Yes, it supports both input types.

-

Q: What are its common industrial applications?

A: Turbines, compressors, pumps, gearboxes, and industrial fans.

-

Q: Does it support alarm and trip functions?

A: Yes, it can trigger alarms and shutdowns via the 3500 rack.

-

Q: What is its operating temperature range?

A: -30°C to +65°C.

-

Q: Is it compatible with other 3500 modules?

A: Yes, it integrates fully into the 3500 rack system.

-

Q: Does it provide real-time monitoring?

A: Yes, continuous real-time vibration and displacement monitoring.

-

Q: What is the power supply requirement for the transducer?

A: The module provides integrated transducer power supply.

-

Q: Can it be used in hazardous environments?

A: Yes, certain configurations meet ATEX and CSA standards.

Bently Nevada 3500/42-04-02 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-04-02

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:31

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-04-02 is a high-performance monitoring module designed to measure and analyze vibration and seismic parameters in critical rotating machinery. It is part of the 3500 machinery protection system and offers real-time monitoring for both proximitor and seismic transducer inputs. This ensures early detection of mechanical issues, reducing unplanned downtime and preventing catastrophic equipment failures.

Product Specifications

| Parameter | Value |

|---|---|

| Module Type | Proximitor / Seismic Monitor |

| Channels | 2 (per module) |

| Input Types | Proximitor® or Seismic transducers |

| Signal Processing | True peak, RMS, 1X, 2X, gap measurements |

| Transducer Power Supply | Integrated |

| Communication | Through 3500 rack system |

| Dimensions (H × W × D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 Series rack |

| Operating Temperature | -30°C to +65°C |

| Certifications | CE, CSA, ATEX (varies with configuration) |

Applications

-

Steam Turbines – Detects imbalance, misalignment, and bearing faults.

-

Gas Turbines – Monitors casing vibrations and rotor displacement.

-

Compressors – Identifies early-stage faults such as surge-induced vibration.

-

Pumps – Ensures smooth operation by monitoring bearing wear and cavitation.

-

Gearboxes – Detects gear mesh defects and lubrication issues.

-

Industrial Fans – Monitors operational vibration for preventive maintenance.

Key Advantages

-

Dual Monitoring Capability – Supports both proximitor and seismic measurements.

-

Advanced Signal Processing – Accurate RMS and peak measurements for precise diagnostics.

-

High Reliability – Designed for continuous industrial operation in harsh environments.

-

Seamless Integration – Fully compatible with the 3500 Series machinery protection system.

-

Flexible Configuration – Allows user-defined alarm and trip settings.

-

Proven Field Performance – Trusted in critical rotating equipment worldwide.

FAQ

-

Q: What is the main function of the 3500/42-04-02?

A: To monitor vibration and seismic parameters for machinery protection.

-

Q: How many channels does the module support?

A: It supports 2 independent monitoring channels.

-

Q: Can it work with both proximitor and seismic transducers?

A: Yes, it supports both input types.

-

Q: What are its common industrial applications?

A: Turbines, compressors, pumps, gearboxes, and industrial fans.

-

Q: Does it support alarm and trip functions?

A: Yes, it can trigger alarms and shutdowns via the 3500 rack.

-

Q: What is its operating temperature range?

A: -30°C to +65°C.

-

Q: Is it compatible with other 3500 modules?

A: Yes, it integrates fully into the 3500 rack system.

-

Q: Does it provide real-time monitoring?

A: Yes, continuous real-time vibration and displacement monitoring.

-

Q: What is the power supply requirement for the transducer?

A: The module provides integrated transducer power supply.

-

Q: Can it be used in hazardous environments?

A: Yes, certain configurations meet ATEX and CSA standards.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...