Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

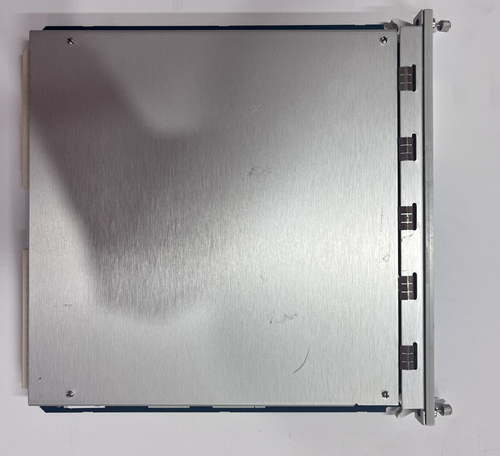

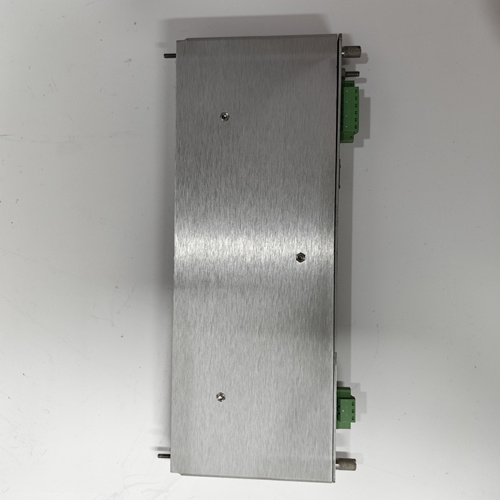

Bently Nevada 330102-00-40-10-01-00 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330102-00-40-10-01-00

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-40-10-01-00 3300 XL 8mm Proximity Probe is a precision sensor designed for reliable shaft position and vibration monitoring in industrial rotating machinery. As part of the 3300 XL series, this probe is well-regarded for its ruggedness and high accuracy, providing essential data for machinery condition monitoring and predictive maintenance.

Built to operate in challenging environments, the 8mm sensing gap allows for precise detection of shaft movement, ensuring early warning of machinery issues such as misalignment, imbalance, or bearing wear. Its stainless steel housing and robust design protect the sensor against harsh conditions including temperature extremes, vibration, and contaminants. The 3300 XL series by Bently Nevada remains a trusted choice worldwide for industrial process reliability.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330102-00-40-10-01-00 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Sensing Distance (Gap) | 8 mm |

| Probe Diameter | 12.7 mm (0.5 inches) |

| Total Length | 1 meter |

| Cable Type | Shielded coaxial cable |

| Operating Temperature Range | -40°C to +120°C |

| Weight | 0.323 kg |

| Housing Material | Stainless steel |

| Connector Type | MIL-style connector |

| Vibration Resistance | High tolerance to industrial vibration |

| Measurement Range | Up to 8 mm sensing distance |

| Accuracy | High sensitivity with micrometer repeatability |

Product Applications

The 3300 XL 8mm Proximity Probe is used extensively across various industries for machinery monitoring, including:

-

Turbines: Monitoring shaft position and vibration to detect potential faults early.

-

Compressors: Ensuring smooth operation by detecting shaft displacement and vibrations.

-

Motors and Generators: Continuous monitoring to prevent unexpected failures.

-

Pumps: Detecting misalignment and bearing wear through vibration analysis.

-

Industrial Machinery: Broad application for rotating equipment health monitoring.

-

Power Plants and Refineries: Critical machinery condition monitoring under harsh environmental conditions.

Product Advantages

-

High Precision: Accurate shaft position and vibration measurements within micrometer tolerances.

-

Robust Design: Stainless steel housing ensures long-term durability in demanding industrial environments.

-

Wide Operating Temperature: Performs reliably between -40°C and +120°C.

-

Resistance to Harsh Conditions: Built to withstand vibration, shock, and contamination.

-

Reliable Connectors: MIL-style connectors ensure secure, stable electrical connections.

-

Compatibility: Fully compatible with the Bently Nevada 3300 XL monitoring system and related components.

-

Minimal Maintenance: Rugged design reduces the need for frequent maintenance and recalibration.

-

Versatile Sensing Range: 8 mm sensing gap accommodates various machinery setups.

-

Industry Trusted: A product of Bently Nevada, a leader in condition monitoring technology.

Frequently Asked Questions (FAQ)

-

Q: What is the sensing gap of this proximity probe?

A: The sensing distance is 8 mm, allowing precise measurement of shaft movement.

-

Q: Can this probe operate in extreme temperatures?

A: Yes, it operates reliably from -40°C up to +120°C.

-

Q: Is the probe compatible with other Bently Nevada monitoring equipment?

A: Yes, it integrates seamlessly with the 3300 XL monitoring system.

-

Q: What type of connector does the probe use?

A: It uses a MIL-style connector, which is industry-standard for secure connections.

-

Q: How heavy is the probe and what are its dimensions?

A: It weighs 0.323 kg and has a diameter of 12.7 mm.

-

Q: Does this probe require frequent calibration?

A: No, its durable design means minimal calibration is needed during normal operation.

-

Q: What kind of cable does it come with?

A: It uses a shielded coaxial cable to ensure accurate signal transmission.

-

Q: Can it detect both shaft position and vibration?

A: Yes, it provides accurate measurements for both parameters.

-

Q: How resistant is the probe to mechanical shock and vibration?

A: It is specifically designed to tolerate high vibration and shock environments typical in industry.

-

Q: Is the probe suitable for use in petrochemical or power plants?

A: Absolutely, it is widely used in power generation and petrochemical industries due to its ruggedness and accuracy.

Bently Nevada 330102-00-40-10-01-00 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330102-00-40-10-01-00

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-40-10-01-00 3300 XL 8mm Proximity Probe is a precision sensor designed for reliable shaft position and vibration monitoring in industrial rotating machinery. As part of the 3300 XL series, this probe is well-regarded for its ruggedness and high accuracy, providing essential data for machinery condition monitoring and predictive maintenance.

Built to operate in challenging environments, the 8mm sensing gap allows for precise detection of shaft movement, ensuring early warning of machinery issues such as misalignment, imbalance, or bearing wear. Its stainless steel housing and robust design protect the sensor against harsh conditions including temperature extremes, vibration, and contaminants. The 3300 XL series by Bently Nevada remains a trusted choice worldwide for industrial process reliability.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330102-00-40-10-01-00 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Sensing Distance (Gap) | 8 mm |

| Probe Diameter | 12.7 mm (0.5 inches) |

| Total Length | 1 meter |

| Cable Type | Shielded coaxial cable |

| Operating Temperature Range | -40°C to +120°C |

| Weight | 0.323 kg |

| Housing Material | Stainless steel |

| Connector Type | MIL-style connector |

| Vibration Resistance | High tolerance to industrial vibration |

| Measurement Range | Up to 8 mm sensing distance |

| Accuracy | High sensitivity with micrometer repeatability |

Product Applications

The 3300 XL 8mm Proximity Probe is used extensively across various industries for machinery monitoring, including:

-

Turbines: Monitoring shaft position and vibration to detect potential faults early.

-

Compressors: Ensuring smooth operation by detecting shaft displacement and vibrations.

-

Motors and Generators: Continuous monitoring to prevent unexpected failures.

-

Pumps: Detecting misalignment and bearing wear through vibration analysis.

-

Industrial Machinery: Broad application for rotating equipment health monitoring.

-

Power Plants and Refineries: Critical machinery condition monitoring under harsh environmental conditions.

Product Advantages

-

High Precision: Accurate shaft position and vibration measurements within micrometer tolerances.

-

Robust Design: Stainless steel housing ensures long-term durability in demanding industrial environments.

-

Wide Operating Temperature: Performs reliably between -40°C and +120°C.

-

Resistance to Harsh Conditions: Built to withstand vibration, shock, and contamination.

-

Reliable Connectors: MIL-style connectors ensure secure, stable electrical connections.

-

Compatibility: Fully compatible with the Bently Nevada 3300 XL monitoring system and related components.

-

Minimal Maintenance: Rugged design reduces the need for frequent maintenance and recalibration.

-

Versatile Sensing Range: 8 mm sensing gap accommodates various machinery setups.

-

Industry Trusted: A product of Bently Nevada, a leader in condition monitoring technology.

Frequently Asked Questions (FAQ)

-

Q: What is the sensing gap of this proximity probe?

A: The sensing distance is 8 mm, allowing precise measurement of shaft movement.

-

Q: Can this probe operate in extreme temperatures?

A: Yes, it operates reliably from -40°C up to +120°C.

-

Q: Is the probe compatible with other Bently Nevada monitoring equipment?

A: Yes, it integrates seamlessly with the 3300 XL monitoring system.

-

Q: What type of connector does the probe use?

A: It uses a MIL-style connector, which is industry-standard for secure connections.

-

Q: How heavy is the probe and what are its dimensions?

A: It weighs 0.323 kg and has a diameter of 12.7 mm.

-

Q: Does this probe require frequent calibration?

A: No, its durable design means minimal calibration is needed during normal operation.

-

Q: What kind of cable does it come with?

A: It uses a shielded coaxial cable to ensure accurate signal transmission.

-

Q: Can it detect both shaft position and vibration?

A: Yes, it provides accurate measurements for both parameters.

-

Q: How resistant is the probe to mechanical shock and vibration?

A: It is specifically designed to tolerate high vibration and shock environments typical in industry.

-

Q: Is the probe suitable for use in petrochemical or power plants?

A: Absolutely, it is widely used in power generation and petrochemical industries due to its ruggedness and accuracy.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...