Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

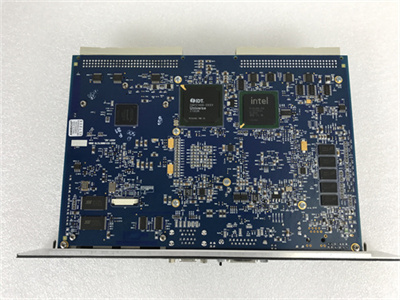

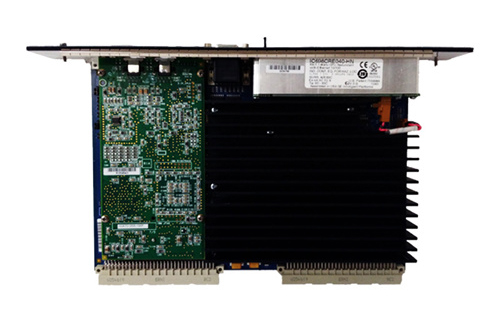

GE Fanuc IC693NIU004 Ethernet Network Interface Module

Manufacturer:General Electric

Part Number:IC693NIU004

Product Type:Ethernet Network Interface Module

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:2.1 cm x 20.2 cm x 26.1 cm

Weight:0.42 kg

Product Description

GE Fanuc IC693NIU004 is an Ethernet network interface module designed for RX3i PACSystems and Series 90-30 Ethernet remote I/O expansion systems. It functions as an Ethernet Global Data (EGD) station, facilitating the exchange of data over the network.

Key Features

- Ethernet Connectivity: Provides high-speed Ethernet communication for distributed I/O systems.

- Global Data Station (EGD): Efficiently exchanges data between the PLC and remote I/O devices.

- Flexibility: Suitable for various industrial automation applications.

- Reliability: Built to endure harsh industrial environments.

Technical Specifications

- Ports:

- 3 Ethernet ports (RJ-45)

- 1 RS-232 port (RJ-11) for station manager access

- LEDs: Indicate module status, link activity, and power supply.

- Ethernet Restart Push Button: Allows for troubleshooting and restarting the Ethernet interface.

- Protocols: Supports multiple Ethernet-based protocols.

- Power Supply: Typically powered by the system bus.

- Mounting: DIN rail or panel mount.

- Environmental: Designed for industrial environments with a wide operating temperature range.

Applications

- Distributed I/O: Connects remote I/O devices to the PLC over Ethernet.

- Machine Automation: Used in various industrial machines for data acquisition and control.

- Process Automation: Employed in process control systems for monitoring and control.

Benefits

- Increased System Flexibility: Facilitates easy expansion and modification of automation systems.

- Improved Performance: Ensures high-speed data transfer and reduced system response time.

- Enhanced Reliability: Guarantees reliable operation in demanding industrial environments.

GE Fanuc IC693NIU004 Ethernet Network Interface Module

Manufacturer:General Electric

Part Number:IC693NIU004

Product Type:Ethernet Network Interface Module

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:2.1 cm x 20.2 cm x 26.1 cm

Weight:0.42 kg

Product Description

GE Fanuc IC693NIU004 is an Ethernet network interface module designed for RX3i PACSystems and Series 90-30 Ethernet remote I/O expansion systems. It functions as an Ethernet Global Data (EGD) station, facilitating the exchange of data over the network.

Key Features

- Ethernet Connectivity: Provides high-speed Ethernet communication for distributed I/O systems.

- Global Data Station (EGD): Efficiently exchanges data between the PLC and remote I/O devices.

- Flexibility: Suitable for various industrial automation applications.

- Reliability: Built to endure harsh industrial environments.

Technical Specifications

- Ports:

- 3 Ethernet ports (RJ-45)

- 1 RS-232 port (RJ-11) for station manager access

- LEDs: Indicate module status, link activity, and power supply.

- Ethernet Restart Push Button: Allows for troubleshooting and restarting the Ethernet interface.

- Protocols: Supports multiple Ethernet-based protocols.

- Power Supply: Typically powered by the system bus.

- Mounting: DIN rail or panel mount.

- Environmental: Designed for industrial environments with a wide operating temperature range.

Applications

- Distributed I/O: Connects remote I/O devices to the PLC over Ethernet.

- Machine Automation: Used in various industrial machines for data acquisition and control.

- Process Automation: Employed in process control systems for monitoring and control.

Benefits

- Increased System Flexibility: Facilitates easy expansion and modification of automation systems.

- Improved Performance: Ensures high-speed data transfer and reduced system response time.

- Enhanced Reliability: Guarantees reliable operation in demanding industrial environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...