Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

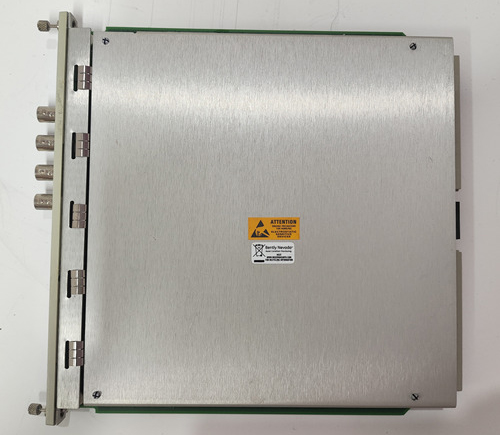

Bently Nevada 330104-05-18-50-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-05-18-50-02-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:5 m

Weight :1.615 kg

Views:181

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-05-18-50-02-00 3300 XL 8 mm Proximity Probe is a high-performance vibration and position measurement sensor used in industrial machinery monitoring. Designed for demanding applications, this probe provides precise displacement measurements of rotating equipment such as turbines, motors, compressors, and pumps. Its 8 mm probe tip diameter ensures accurate readings while minimizing interference from environmental vibrations. Engineered for the Bently Nevada 3300 XL series monitoring systems, it is widely recognized for reliability, robustness, and seamless integration with condition monitoring systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330104-05-18-50-02-00 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Measurement Range | ±0.254 mm (±10 mils) |

| Operating Temperature | -40°C to 120°C |

| Total Length | 5 m |

| Housing Material | Stainless Steel |

| Connector Type | MS-type |

| Weight | 1.615 kg |

| Electrical Interface | AC/DC compatible |

| Maximum Excitation Voltage | 24 V DC |

| Frequency Response | 0–25 kHz |

| Mounting | Threaded or clamp mount compatible |

Product Applications

Turbine Monitoring – Measures rotor displacement and vibration for steam, gas, and hydro turbines.

Motor Monitoring – Provides continuous feedback for high-speed motors in critical plants.

Compressor Monitoring – Ensures precise shaft position measurements for centrifugal and reciprocating compressors.

Pump Monitoring – Detects imbalance and misalignment in high-speed centrifugal and axial pumps.

Condition-Based Maintenance – Integrated into vibration monitoring systems to predict maintenance needs and prevent failures.

Industrial Process Control – Supports machinery diagnostics in petrochemical, power generation, and manufacturing sectors.

Product Advantages

High Accuracy – Offers precise shaft displacement measurements with minimal signal distortion.

Rugged Construction – Stainless steel housing and durable tip designed for harsh industrial environments.

Wide Temperature Range – Reliable performance from -40°C to 120°C.

Seamless Integration – Compatible with Bently Nevada 3300 XL monitoring systems for simplified installation.

Fast Response – Frequency response up to 25 kHz enables accurate detection of high-speed events.

Low Maintenance – Designed for long-term operation without frequent adjustments or calibration.

FAQ

Q1: What type of signal does the 3300 XL 8 mm Proximity Probe produce?

A1: It generates a variable AC signal proportional to the displacement between the probe and target shaft.

Q2: Can this probe operate in explosive environments?

A2: Yes, it can be paired with intrinsically safe barriers for hazardous area applications.

Q3: How do I verify probe installation alignment?

A3: Use a micrometer or feeler gauge to measure the probe tip gap relative to the shaft and ensure it matches system specifications.

Q4: What is the typical cable length available?

A4: Standard cable length is 1 meters, with options for custom lengths upon request.

Q5: Is this probe compatible with older 3300 Series systems?

A5: It is primarily designed for 3300 XL systems but may be compatible with previous models using proper adapters.

Q6: What is the maximum vibration frequency it can measure?

A6: The probe supports up to 25 kHz frequency response, suitable for high-speed machinery monitoring.

Q7: How does temperature affect the measurement signal?

A7: The probe maintains accuracy within -40°C to 120°C; extreme temperatures may slightly affect signal amplitude but remain within operational tolerance.

Q8: Can the probe measure both displacement and vibration simultaneously?

A8: Yes, when integrated into the 3300 XL system, it can provide both shaft displacement and vibration data.

Q9: What is the recommended mounting method for optimal performance?

A9: Threaded mounting on a rigid support or using a clamp mount near the rotor shaft is recommended for stable measurements.

Q10: How do I prevent electrical noise from affecting the probe signal?

A10: Use shielded cables and proper grounding techniques as outlined in the 3300 XL system installation guide.

Bently Nevada 330104-05-18-50-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-05-18-50-02-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:5 m

Weight :1.615 kg

Views:181

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-05-18-50-02-00 3300 XL 8 mm Proximity Probe is a high-performance vibration and position measurement sensor used in industrial machinery monitoring. Designed for demanding applications, this probe provides precise displacement measurements of rotating equipment such as turbines, motors, compressors, and pumps. Its 8 mm probe tip diameter ensures accurate readings while minimizing interference from environmental vibrations. Engineered for the Bently Nevada 3300 XL series monitoring systems, it is widely recognized for reliability, robustness, and seamless integration with condition monitoring systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330104-05-18-50-02-00 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Measurement Range | ±0.254 mm (±10 mils) |

| Operating Temperature | -40°C to 120°C |

| Total Length | 5 m |

| Housing Material | Stainless Steel |

| Connector Type | MS-type |

| Weight | 1.615 kg |

| Electrical Interface | AC/DC compatible |

| Maximum Excitation Voltage | 24 V DC |

| Frequency Response | 0–25 kHz |

| Mounting | Threaded or clamp mount compatible |

Product Applications

Turbine Monitoring – Measures rotor displacement and vibration for steam, gas, and hydro turbines.

Motor Monitoring – Provides continuous feedback for high-speed motors in critical plants.

Compressor Monitoring – Ensures precise shaft position measurements for centrifugal and reciprocating compressors.

Pump Monitoring – Detects imbalance and misalignment in high-speed centrifugal and axial pumps.

Condition-Based Maintenance – Integrated into vibration monitoring systems to predict maintenance needs and prevent failures.

Industrial Process Control – Supports machinery diagnostics in petrochemical, power generation, and manufacturing sectors.

Product Advantages

High Accuracy – Offers precise shaft displacement measurements with minimal signal distortion.

Rugged Construction – Stainless steel housing and durable tip designed for harsh industrial environments.

Wide Temperature Range – Reliable performance from -40°C to 120°C.

Seamless Integration – Compatible with Bently Nevada 3300 XL monitoring systems for simplified installation.

Fast Response – Frequency response up to 25 kHz enables accurate detection of high-speed events.

Low Maintenance – Designed for long-term operation without frequent adjustments or calibration.

FAQ

Q1: What type of signal does the 3300 XL 8 mm Proximity Probe produce?

A1: It generates a variable AC signal proportional to the displacement between the probe and target shaft.

Q2: Can this probe operate in explosive environments?

A2: Yes, it can be paired with intrinsically safe barriers for hazardous area applications.

Q3: How do I verify probe installation alignment?

A3: Use a micrometer or feeler gauge to measure the probe tip gap relative to the shaft and ensure it matches system specifications.

Q4: What is the typical cable length available?

A4: Standard cable length is 1 meters, with options for custom lengths upon request.

Q5: Is this probe compatible with older 3300 Series systems?

A5: It is primarily designed for 3300 XL systems but may be compatible with previous models using proper adapters.

Q6: What is the maximum vibration frequency it can measure?

A6: The probe supports up to 25 kHz frequency response, suitable for high-speed machinery monitoring.

Q7: How does temperature affect the measurement signal?

A7: The probe maintains accuracy within -40°C to 120°C; extreme temperatures may slightly affect signal amplitude but remain within operational tolerance.

Q8: Can the probe measure both displacement and vibration simultaneously?

A8: Yes, when integrated into the 3300 XL system, it can provide both shaft displacement and vibration data.

Q9: What is the recommended mounting method for optimal performance?

A9: Threaded mounting on a rigid support or using a clamp mount near the rotor shaft is recommended for stable measurements.

Q10: How do I prevent electrical noise from affecting the probe signal?

A10: Use shielded cables and proper grounding techniques as outlined in the 3300 XL system installation guide.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...