Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

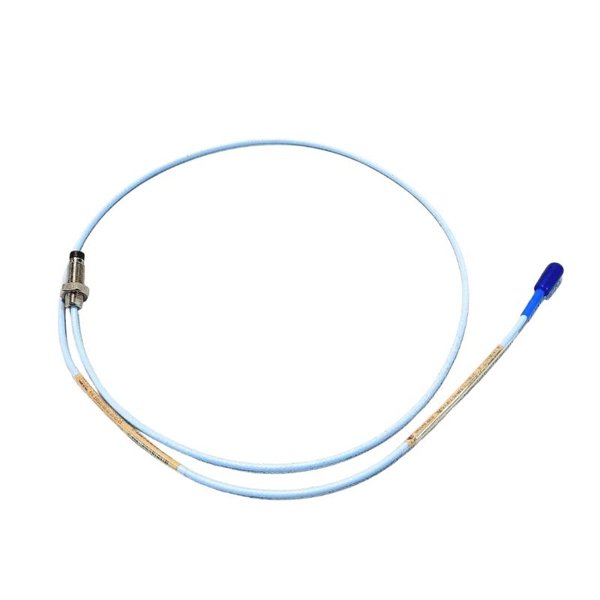

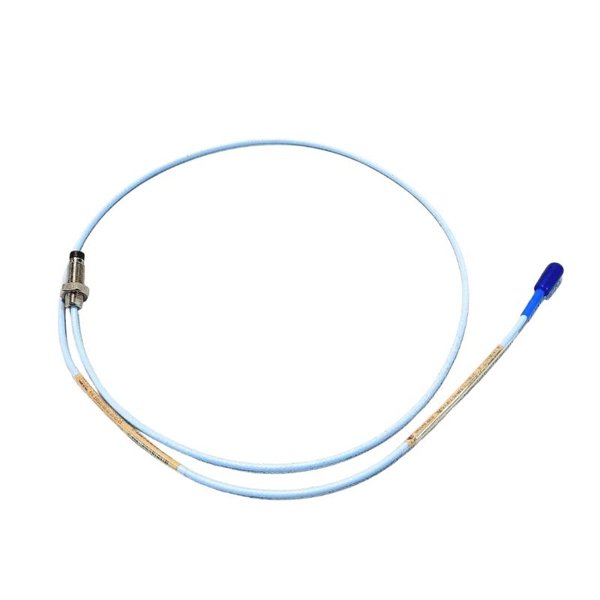

Bently Nevada 330191-00-40-90-02-00 3300 XL 8 mm ETR Probe

Manufacturer:Bently Nevada

Product Number:330191-00-40-90-02-00

Product Type:3300 XL 8 mm ETR Probe

Origin:USA

Total Length:9 meters

Weight:2.907 kg

Views:101

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330191-00-40-90-02-00 3300 XL 8 mm ETR Probe is a precision-engineered proximity probe designed for continuous, non-contact measurement of shaft vibration and displacement in critical rotating machinery. Belonging to the 3300 XL series, this probe is optimized for applications that demand long probe-to-monitor distances while maintaining exceptional linearity and signal stability. With a total length of 9.0 meters and an 8 mm tip diameter, it ensures accurate data acquisition in environments where equipment is subject to high temperatures, electrical noise, and mechanical stress. Its stainless-steel construction and advanced insulation make it ideal for use in power generation, petrochemical plants, and heavy industrial applications where reliability and accuracy are essential.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330191-00-40-90-02-00 |

| Product Type | 3300 XL 8 mm ETR Proximity Probe |

| Total Length | 9.0 meters |

| Probe Tip Diameter | 8 mm |

| Weight | 2.907 kg |

| Linear Range | 2.0 mm (80 mils) nominal |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | DC to 10 kHz |

| Operating Temperature | –35 °C to +177 °C |

| Pressure Rating | Up to 10 bar |

| Mounting Thread | 3/8–24 UNF or compatible mounting hardware |

| Insulation Resistance | ≥10 GΩ at 500 VDC |

| Material | Stainless steel body with PEEK high-dielectric insulation |

| Compliance | CE, RoHS |

Applications

The 330191-00-40-90-02-00 probe is used extensively in industries that require accurate vibration and displacement measurements, including:

Gas and Steam Turbines – Monitoring shaft vibration for predictive maintenance and protection against catastrophic failures.

Compressors and Pumps – Identifying early signs of imbalance, misalignment, or mechanical looseness.

Large Motors and Generators – Tracking rotor dynamics for reliable long-term operation.

Petrochemical Equipment – Performing in hazardous and corrosive atmospheres with stable measurement performance.

Industrial Machinery – Supporting continuous condition monitoring in high-demand production facilities.

Advantages

Extended 9 m Cable Length – Designed for installations requiring long probe-to-monitor distances without signal loss.

High Measurement Accuracy – 8 mm tip provides a wide linear range for precise displacement detection.

Superior Noise Immunity – Coaxial cable design and matched impedance ensure signal integrity in high-EMI environments.

Robust Stainless-Steel Body – Offers excellent corrosion resistance and long operational life in harsh conditions.

Wide Operating Temperature Range – Functions reliably from –35 °C to +177 °C.

Pressure-Resistant Design – Suitable for environments with pressures up to 10 bar.

Seamless System Integration – Fully compatible with Bently Nevada 3300 XL Proximitor sensors and 3500 series monitors.

Ease of Installation – Standard 3/8–24 UNF thread simplifies retrofitting and new equipment installation.

FAQ

What is the nominal linear range of this probe?

The probe provides a nominal linear range of 2.0 mm (80 mils) for accurate shaft displacement measurement.

How is signal fidelity maintained over the 9 m length?

The probe uses low-noise coaxial cable with controlled impedance to preserve signal integrity.

Is it directly compatible with 3300 XL Proximitor sensors?

Yes, it is fully compatible and requires no additional adapters.

What is the standard sensitivity rating?

Sensitivity is approximately 7.87 V/mm (200 mV/mil), ensuring precise vibration measurement.

Can this probe monitor high-frequency vibration?

Yes, it supports a frequency response from DC to 10 kHz.

Which mounting thread is recommended for secure installation?

A 3/8–24 UNF thread or equivalent housing is recommended.

Does it require external shielding in environments with high electrical noise?

No, its internal coaxial shielding minimizes the need for additional protection.

Is it capable of operating in high-pressure applications?

Yes, the probe is rated for use in environments up to 10 bar pressure.

How does it handle thermal expansion across its operating range?

It is factory-calibrated to maintain accuracy between –35 °C and +177 °C.

Is it suitable for classified hazardous areas?

Yes, when paired with certified Proximitor systems, it meets many hazardous area requirements.

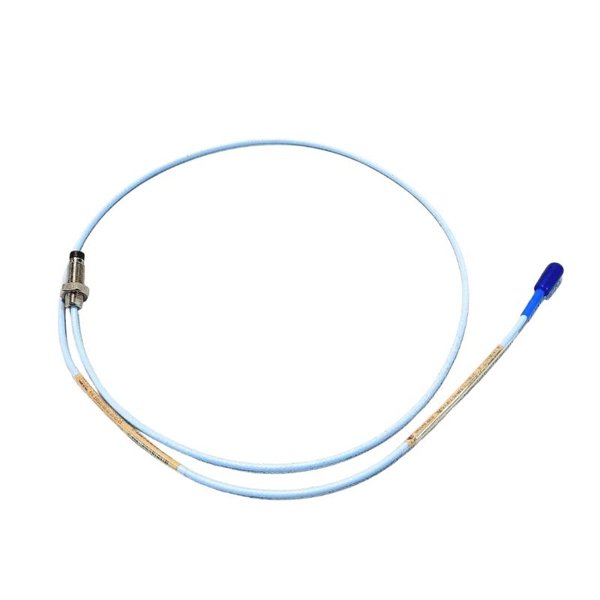

Bently Nevada 330191-00-40-90-02-00 3300 XL 8 mm ETR Probe

Manufacturer:Bently Nevada

Product Number:330191-00-40-90-02-00

Product Type:3300 XL 8 mm ETR Probe

Origin:USA

Total Length:9 meters

Weight:2.907 kg

Views:101

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330191-00-40-90-02-00 3300 XL 8 mm ETR Probe is a precision-engineered proximity probe designed for continuous, non-contact measurement of shaft vibration and displacement in critical rotating machinery. Belonging to the 3300 XL series, this probe is optimized for applications that demand long probe-to-monitor distances while maintaining exceptional linearity and signal stability. With a total length of 9.0 meters and an 8 mm tip diameter, it ensures accurate data acquisition in environments where equipment is subject to high temperatures, electrical noise, and mechanical stress. Its stainless-steel construction and advanced insulation make it ideal for use in power generation, petrochemical plants, and heavy industrial applications where reliability and accuracy are essential.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330191-00-40-90-02-00 |

| Product Type | 3300 XL 8 mm ETR Proximity Probe |

| Total Length | 9.0 meters |

| Probe Tip Diameter | 8 mm |

| Weight | 2.907 kg |

| Linear Range | 2.0 mm (80 mils) nominal |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | DC to 10 kHz |

| Operating Temperature | –35 °C to +177 °C |

| Pressure Rating | Up to 10 bar |

| Mounting Thread | 3/8–24 UNF or compatible mounting hardware |

| Insulation Resistance | ≥10 GΩ at 500 VDC |

| Material | Stainless steel body with PEEK high-dielectric insulation |

| Compliance | CE, RoHS |

Applications

The 330191-00-40-90-02-00 probe is used extensively in industries that require accurate vibration and displacement measurements, including:

Gas and Steam Turbines – Monitoring shaft vibration for predictive maintenance and protection against catastrophic failures.

Compressors and Pumps – Identifying early signs of imbalance, misalignment, or mechanical looseness.

Large Motors and Generators – Tracking rotor dynamics for reliable long-term operation.

Petrochemical Equipment – Performing in hazardous and corrosive atmospheres with stable measurement performance.

Industrial Machinery – Supporting continuous condition monitoring in high-demand production facilities.

Advantages

Extended 9 m Cable Length – Designed for installations requiring long probe-to-monitor distances without signal loss.

High Measurement Accuracy – 8 mm tip provides a wide linear range for precise displacement detection.

Superior Noise Immunity – Coaxial cable design and matched impedance ensure signal integrity in high-EMI environments.

Robust Stainless-Steel Body – Offers excellent corrosion resistance and long operational life in harsh conditions.

Wide Operating Temperature Range – Functions reliably from –35 °C to +177 °C.

Pressure-Resistant Design – Suitable for environments with pressures up to 10 bar.

Seamless System Integration – Fully compatible with Bently Nevada 3300 XL Proximitor sensors and 3500 series monitors.

Ease of Installation – Standard 3/8–24 UNF thread simplifies retrofitting and new equipment installation.

FAQ

What is the nominal linear range of this probe?

The probe provides a nominal linear range of 2.0 mm (80 mils) for accurate shaft displacement measurement.

How is signal fidelity maintained over the 9 m length?

The probe uses low-noise coaxial cable with controlled impedance to preserve signal integrity.

Is it directly compatible with 3300 XL Proximitor sensors?

Yes, it is fully compatible and requires no additional adapters.

What is the standard sensitivity rating?

Sensitivity is approximately 7.87 V/mm (200 mV/mil), ensuring precise vibration measurement.

Can this probe monitor high-frequency vibration?

Yes, it supports a frequency response from DC to 10 kHz.

Which mounting thread is recommended for secure installation?

A 3/8–24 UNF thread or equivalent housing is recommended.

Does it require external shielding in environments with high electrical noise?

No, its internal coaxial shielding minimizes the need for additional protection.

Is it capable of operating in high-pressure applications?

Yes, the probe is rated for use in environments up to 10 bar pressure.

How does it handle thermal expansion across its operating range?

It is factory-calibrated to maintain accuracy between –35 °C and +177 °C.

Is it suitable for classified hazardous areas?

Yes, when paired with certified Proximitor systems, it meets many hazardous area requirements.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...