Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

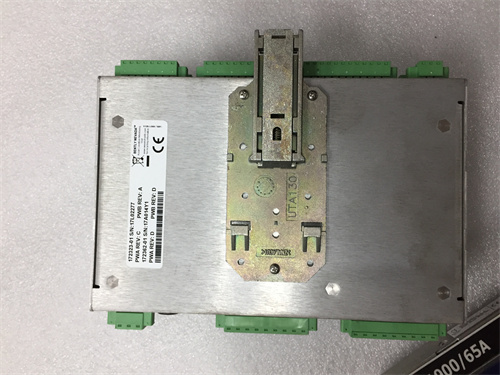

Bently Nevada 9200-09-01-01-00 Seismoprobe Velocity Transducers

Brand:Bently Nevada

Model Number:9200-09-01-01-00

Type:Seismoprobe Velocity Transducers

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD87

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 9200-09-01-01-00 is a high-precision, two-wire velocity transducer. It measures vibration in industrial machinery and equipment, providing real-time data for predictive maintenance. This versatile tool monitors the health of rotating machinery, enabling proactive maintenance strategies.

Key Features and Specifications

Measurement

The transducer measures velocity, directly indicating the severity of vibration and potential machine faults.

Two-Wire Design

The device’s two-wire design eliminates the need for an external power supply, making it ideal for remote and hazardous environments.

Rugged Construction

This transducer withstands harsh industrial conditions, ensuring long-term reliable performance.

High Sensitivity

The transducer accurately detects small vibration changes, enabling early detection of potential issues.

Wide Frequency Range

It measures a broad range of frequencies, making it suitable for various applications.

Mounting Options

The transducer offers different mounting angles to accommodate diverse installation requirements.

Compatibility

It seamlessly integrates with Bently Nevada’s suite of condition monitoring systems, enhancing data analysis.

Applications

Rotating Machinery

The transducer monitors vibration in turbines, compressors, pumps, and other rotating equipment, detecting imbalances, misalignment, bearing wear, and other faults.

Structural Monitoring

The device measures vibration in structures to assess their integrity and detect potential damage.

Predictive Maintenance

The transducer supports condition-based maintenance strategies, reducing downtime and optimizing maintenance costs.

Research and Development

It facilitates vibration analysis studies, improving machinery design and performance.

Benefits

- Early Fault Detection: The transducer identifies potential problems before they cause costly equipment failures.

- Increased Reliability: It improves the overall reliability and availability of machinery.

- Reduced Maintenance Costs: The device optimizes maintenance activities, minimizing unplanned downtime.

- Improved Safety: It detects and addresses potential safety hazards before they occur.

Bently Nevada 9200-09-01-01-00 Seismoprobe Velocity Transducers

Brand:Bently Nevada

Model Number:9200-09-01-01-00

Type:Seismoprobe Velocity Transducers

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD87

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 9200-09-01-01-00 is a high-precision, two-wire velocity transducer. It measures vibration in industrial machinery and equipment, providing real-time data for predictive maintenance. This versatile tool monitors the health of rotating machinery, enabling proactive maintenance strategies.

Key Features and Specifications

Measurement

The transducer measures velocity, directly indicating the severity of vibration and potential machine faults.

Two-Wire Design

The device’s two-wire design eliminates the need for an external power supply, making it ideal for remote and hazardous environments.

Rugged Construction

This transducer withstands harsh industrial conditions, ensuring long-term reliable performance.

High Sensitivity

The transducer accurately detects small vibration changes, enabling early detection of potential issues.

Wide Frequency Range

It measures a broad range of frequencies, making it suitable for various applications.

Mounting Options

The transducer offers different mounting angles to accommodate diverse installation requirements.

Compatibility

It seamlessly integrates with Bently Nevada’s suite of condition monitoring systems, enhancing data analysis.

Applications

Rotating Machinery

The transducer monitors vibration in turbines, compressors, pumps, and other rotating equipment, detecting imbalances, misalignment, bearing wear, and other faults.

Structural Monitoring

The device measures vibration in structures to assess their integrity and detect potential damage.

Predictive Maintenance

The transducer supports condition-based maintenance strategies, reducing downtime and optimizing maintenance costs.

Research and Development

It facilitates vibration analysis studies, improving machinery design and performance.

Benefits

- Early Fault Detection: The transducer identifies potential problems before they cause costly equipment failures.

- Increased Reliability: It improves the overall reliability and availability of machinery.

- Reduced Maintenance Costs: The device optimizes maintenance activities, minimizing unplanned downtime.

- Improved Safety: It detects and addresses potential safety hazards before they occur.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...