Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

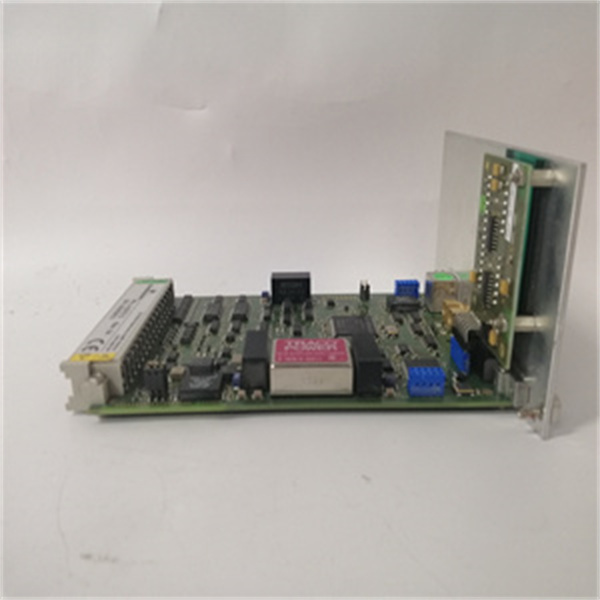

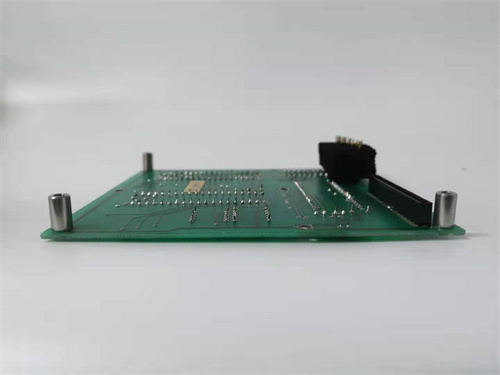

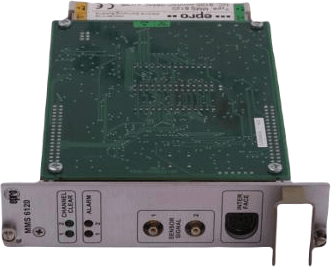

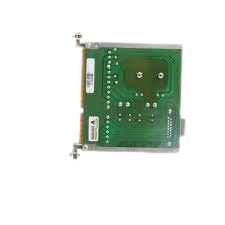

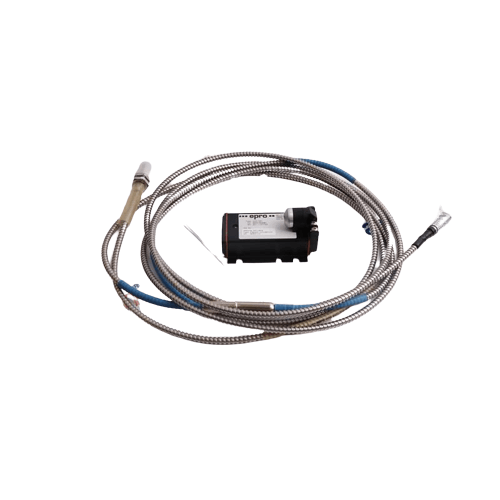

Emerson PR6424/010-010 Non-Contact displacement transducer sensor

Brand: Emerson

Model Number: PR6424/010-010

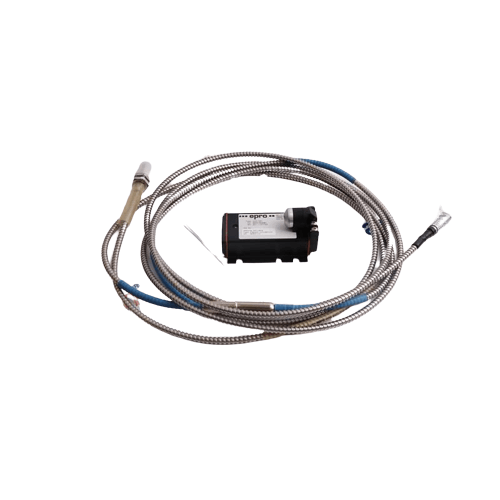

Type: Non-contact displacement transducer sensor

Product Origin: United States

Payment: T/T, Western Union, Credit Card

Dimensions: 100mm x 50mm x 20mm

Weight: 100g

Certificate: CE, RoHS

Warranty: 1 year

Product Description

The Emerson EPRO PR6424/010-010 Sensor module is a non-contact displacement transducer sensor that measures radial and axial shaft dynamic displacement, position, eccentricity, and speed. It is designed for critical turbomachinery applications such as steam, gas, and hydro turbines, compressors, gearboxes, pumps, and fans.

Features

- High-precision measurement: The sensor module provides accurate and reliable measurements.

- Wide range of applications: It can be used in various industries and environments.

- Robust construction: The module is built to withstand harsh conditions and ensure long-term durability.

- Easy installation: It can be easily installed and integrated into existing systems.

- Real-time monitoring: The module enables continuous monitoring of critical parameters.

Technical specifications

| Feature | Specification |

|---|---|

| Operating temperature range | -40°C to +85°C |

| Accuracy | ±0.002mm |

| Repeatability | ±0.001mm |

| Weight | 0.3kg |

| Dimensions | 3.1×19.1×12.8cm |

Benefits

- Improved reliability and uptime

- Reduced maintenance costs

- Increased safety

- Improved efficiency

Applications

The Emerson EPRO PR6424/010-010 Sensor Module finds application in various industries, including:

- Oil and Gas: Used for monitoring pressure, temperature, and vibration in drilling and production equipment.

- Power Generation: Enables precise monitoring of turbine performance and generator conditions.

- Chemical Processing: Provides accurate measurement of critical parameters in chemical manufacturing processes.

- Manufacturing: Used for quality control, condition monitoring, and predictive maintenance in production lines.

Emerson PR6424/010-010 Non-Contact displacement transducer sensor

Brand: Emerson

Model Number: PR6424/010-010

Type: Non-contact displacement transducer sensor

Product Origin: United States

Payment: T/T, Western Union, Credit Card

Dimensions: 100mm x 50mm x 20mm

Weight: 100g

Certificate: CE, RoHS

Warranty: 1 year

Product Description

The Emerson EPRO PR6424/010-010 Sensor module is a non-contact displacement transducer sensor that measures radial and axial shaft dynamic displacement, position, eccentricity, and speed. It is designed for critical turbomachinery applications such as steam, gas, and hydro turbines, compressors, gearboxes, pumps, and fans.

Features

- High-precision measurement: The sensor module provides accurate and reliable measurements.

- Wide range of applications: It can be used in various industries and environments.

- Robust construction: The module is built to withstand harsh conditions and ensure long-term durability.

- Easy installation: It can be easily installed and integrated into existing systems.

- Real-time monitoring: The module enables continuous monitoring of critical parameters.

Technical specifications

| Feature | Specification |

|---|---|

| Operating temperature range | -40°C to +85°C |

| Accuracy | ±0.002mm |

| Repeatability | ±0.001mm |

| Weight | 0.3kg |

| Dimensions | 3.1×19.1×12.8cm |

Benefits

- Improved reliability and uptime

- Reduced maintenance costs

- Increased safety

- Improved efficiency

Applications

The Emerson EPRO PR6424/010-010 Sensor Module finds application in various industries, including:

- Oil and Gas: Used for monitoring pressure, temperature, and vibration in drilling and production equipment.

- Power Generation: Enables precise monitoring of turbine performance and generator conditions.

- Chemical Processing: Provides accurate measurement of critical parameters in chemical manufacturing processes.

- Manufacturing: Used for quality control, condition monitoring, and predictive maintenance in production lines.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...