Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

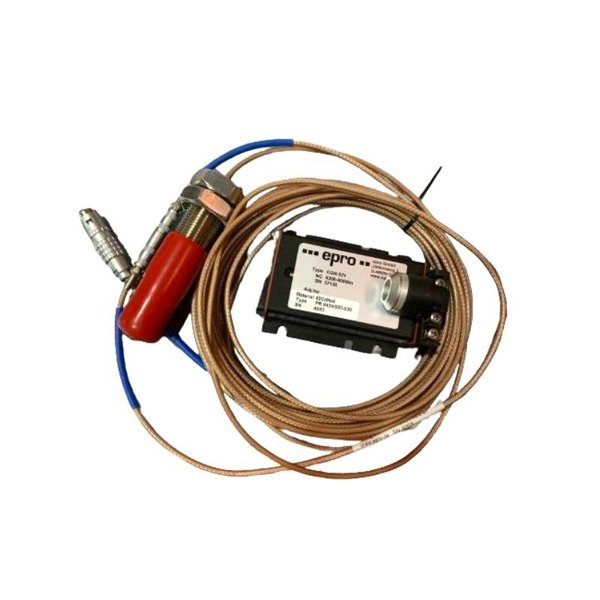

Epro PR6424/111-021 16mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6424/111-021

Product Type:16mm Eddy Current Sensor

Origin:Germany

Sensor head diameter:16mm

Weight:0.2 kg

Views:77

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6424/111-021 is a 16mm eddy current sensor that offers non-contact displacement, vibration, and position measurement for high-precision industrial applications. This sensor operates based on the eddy current principle, where an oscillating magnetic field induces eddy currents in the conductive target material. Variations in these currents are detected by the sensor, and the distance between the sensor and the target is determined based on these fluctuations.

The PR6424/111-021 is designed for machine condition monitoring, vibration analysis, and position sensing across a variety of industries such as automotive, aerospace, power generation, and manufacturing. This sensor provides high accuracy, high-frequency response, and robust performance, making it ideal for both static and dynamic measurement in challenging environments.

Product Specifications

| Feature | Specification |

|---|---|

| Sensor Type | Eddy Current Sensor |

| Sensing Head Diameter | 16 mm |

| Weight | 0.2 kg |

| Measurement Range | Up to 10 mm |

| Output Type | Analog or Digital (depending on model) |

| Temperature Range | -20°C to +80°C |

| Operating Frequency | High-frequency response |

| Power Supply | 15–30V DC |

| Accuracy | ±0.1% of full scale |

| Resolution | 0.01 mm |

| Material | Stainless steel, corrosion-resistant |

Applications

The Epro PR6424/111-021 eddy current sensor is highly versatile and can be used in various industrial applications, including:

Condition Monitoring: Continuously monitors the condition of machinery, such as motors, bearings, and turbines, helping to identify early signs of wear, misalignment, and vibration issues.

Vibration Measurement: Measures the vibration and displacement in rotating machinery, such as compressors, pumps, and turbines, to ensure safe and efficient operation.

Position Sensing: Measures displacement and position in automated systems, such as robotic arms, actuators, and pistons, used in manufacturing and assembly lines.

Non-Contact Measurement: Ideal for applications where traditional contact sensors cannot be used, such as high-speed or hazardous environments.

Power Generation: Used for turbine monitoring, vibration analysis, and machine performance evaluation in power plants.

Aerospace and Automotive: Used for testing, inspection, and alignment in the aerospace and automotive industries to ensure the precision of components and assemblies.

Product Advantages

Non-Contact Measurement: The PR6424/111-021 utilizes eddy current technology, which eliminates the need for physical contact with the target. This prevents sensor wear, ideal for high-speed machinery or environments where contact-based sensors cannot be used.

High Accuracy: With ±0.1% accuracy, the sensor provides extremely precise measurements, essential for applications requiring high precision.

Compact and Robust Design: The 16mm diameter sensing head is compact yet durable, built with stainless steel to withstand harsh industrial environments, including corrosive conditions.

High-Frequency Response: The sensor is capable of providing real-time dynamic measurements, making it well-suited for vibration monitoring in rotating machinery.

Versatile Output Options: The sensor can provide both analog and digital outputs, offering flexibility for integration into various systems.

Wide Temperature Range: The PR6424/111-021 operates efficiently in temperatures ranging from -20°C to +80°C, making it suitable for a wide range of industrial environments.

Easy Integration: The sensor can be easily integrated with existing data acquisition systems, signal conditioners, and monitoring platforms.

Long-Term Stability: Known for its long-term performance, the sensor provides reliable results over extended periods with minimal maintenance required.

Energy-Efficient: The sensor uses low power supply requirements (15–30V DC), reducing operational costs and increasing energy efficiency in your system.

FAQ

1. How does the Epro PR6424/111-021 sensor work?

The PR6424/111-021 works on the eddy current principle. The sensor creates a magnetic field that induces eddy currents in the conductive material of the target. Changes in these currents are measured to determine the distance between the sensor and the target.

2. What is the measurement range of the sensor?

The PR6424/111-021 has a displacement measurement range of up to 10 mm.

3. Can this sensor measure vibration?

Yes, the PR6424/111-021 is excellent for measuring both displacement and vibration in rotating machinery, such as turbines and motors.

4. What outputs are available from this sensor?

The PR6424/111-021 provides both analog and digital outputs, which makes it flexible for integration with various systems.

5. What is the accuracy of the sensor?

The sensor provides an accuracy of ±0.1% of the full scale, offering precise and reliable measurements for critical applications.

6. What temperature range can the sensor handle?

The sensor operates within a temperature range of -20°C to +80°C, making it suitable for use in harsh industrial environments.

7. Can the sensor be used for position sensing?

Yes, the PR6424/111-021 is ideal for position sensing applications, such as monitoring the position of actuators, pistons, and sliders in automation systems.

8. Is the sensor suitable for non-contact applications?

Yes, the PR6424/111-021 uses eddy current technology, which allows for non-contact measurements, ideal for high-speed and hazardous environments.

9. Can the sensor be used in aerospace and automotive applications?

Yes, the PR6424/111-021 is widely used in the aerospace and automotive industries for precision measurement of components, ensuring proper alignment and testing.

10. How does the sensor help in machine condition monitoring?

The PR6424/111-021 is used to monitor the displacement and vibration of machinery, providing early warning signs of issues such as misalignment, wear, or imbalance, which helps to prevent failures and reduce maintenance costs.

Epro PR6424/111-021 16mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6424/111-021

Product Type:16mm Eddy Current Sensor

Origin:Germany

Sensor head diameter:16mm

Weight:0.2 kg

Views:77

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6424/111-021 is a 16mm eddy current sensor that offers non-contact displacement, vibration, and position measurement for high-precision industrial applications. This sensor operates based on the eddy current principle, where an oscillating magnetic field induces eddy currents in the conductive target material. Variations in these currents are detected by the sensor, and the distance between the sensor and the target is determined based on these fluctuations.

The PR6424/111-021 is designed for machine condition monitoring, vibration analysis, and position sensing across a variety of industries such as automotive, aerospace, power generation, and manufacturing. This sensor provides high accuracy, high-frequency response, and robust performance, making it ideal for both static and dynamic measurement in challenging environments.

Product Specifications

| Feature | Specification |

|---|---|

| Sensor Type | Eddy Current Sensor |

| Sensing Head Diameter | 16 mm |

| Weight | 0.2 kg |

| Measurement Range | Up to 10 mm |

| Output Type | Analog or Digital (depending on model) |

| Temperature Range | -20°C to +80°C |

| Operating Frequency | High-frequency response |

| Power Supply | 15–30V DC |

| Accuracy | ±0.1% of full scale |

| Resolution | 0.01 mm |

| Material | Stainless steel, corrosion-resistant |

Applications

The Epro PR6424/111-021 eddy current sensor is highly versatile and can be used in various industrial applications, including:

Condition Monitoring: Continuously monitors the condition of machinery, such as motors, bearings, and turbines, helping to identify early signs of wear, misalignment, and vibration issues.

Vibration Measurement: Measures the vibration and displacement in rotating machinery, such as compressors, pumps, and turbines, to ensure safe and efficient operation.

Position Sensing: Measures displacement and position in automated systems, such as robotic arms, actuators, and pistons, used in manufacturing and assembly lines.

Non-Contact Measurement: Ideal for applications where traditional contact sensors cannot be used, such as high-speed or hazardous environments.

Power Generation: Used for turbine monitoring, vibration analysis, and machine performance evaluation in power plants.

Aerospace and Automotive: Used for testing, inspection, and alignment in the aerospace and automotive industries to ensure the precision of components and assemblies.

Product Advantages

Non-Contact Measurement: The PR6424/111-021 utilizes eddy current technology, which eliminates the need for physical contact with the target. This prevents sensor wear, ideal for high-speed machinery or environments where contact-based sensors cannot be used.

High Accuracy: With ±0.1% accuracy, the sensor provides extremely precise measurements, essential for applications requiring high precision.

Compact and Robust Design: The 16mm diameter sensing head is compact yet durable, built with stainless steel to withstand harsh industrial environments, including corrosive conditions.

High-Frequency Response: The sensor is capable of providing real-time dynamic measurements, making it well-suited for vibration monitoring in rotating machinery.

Versatile Output Options: The sensor can provide both analog and digital outputs, offering flexibility for integration into various systems.

Wide Temperature Range: The PR6424/111-021 operates efficiently in temperatures ranging from -20°C to +80°C, making it suitable for a wide range of industrial environments.

Easy Integration: The sensor can be easily integrated with existing data acquisition systems, signal conditioners, and monitoring platforms.

Long-Term Stability: Known for its long-term performance, the sensor provides reliable results over extended periods with minimal maintenance required.

Energy-Efficient: The sensor uses low power supply requirements (15–30V DC), reducing operational costs and increasing energy efficiency in your system.

FAQ

1. How does the Epro PR6424/111-021 sensor work?

The PR6424/111-021 works on the eddy current principle. The sensor creates a magnetic field that induces eddy currents in the conductive material of the target. Changes in these currents are measured to determine the distance between the sensor and the target.

2. What is the measurement range of the sensor?

The PR6424/111-021 has a displacement measurement range of up to 10 mm.

3. Can this sensor measure vibration?

Yes, the PR6424/111-021 is excellent for measuring both displacement and vibration in rotating machinery, such as turbines and motors.

4. What outputs are available from this sensor?

The PR6424/111-021 provides both analog and digital outputs, which makes it flexible for integration with various systems.

5. What is the accuracy of the sensor?

The sensor provides an accuracy of ±0.1% of the full scale, offering precise and reliable measurements for critical applications.

6. What temperature range can the sensor handle?

The sensor operates within a temperature range of -20°C to +80°C, making it suitable for use in harsh industrial environments.

7. Can the sensor be used for position sensing?

Yes, the PR6424/111-021 is ideal for position sensing applications, such as monitoring the position of actuators, pistons, and sliders in automation systems.

8. Is the sensor suitable for non-contact applications?

Yes, the PR6424/111-021 uses eddy current technology, which allows for non-contact measurements, ideal for high-speed and hazardous environments.

9. Can the sensor be used in aerospace and automotive applications?

Yes, the PR6424/111-021 is widely used in the aerospace and automotive industries for precision measurement of components, ensuring proper alignment and testing.

10. How does the sensor help in machine condition monitoring?

The PR6424/111-021 is used to monitor the displacement and vibration of machinery, providing early warning signs of issues such as misalignment, wear, or imbalance, which helps to prevent failures and reduce maintenance costs.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...