Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

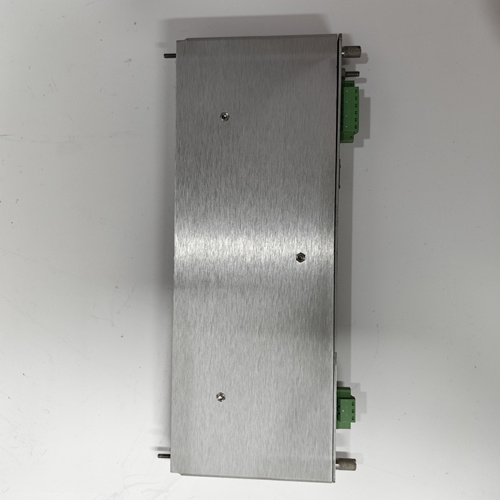

Bently Nevada 330104-02-08-90-01-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-02-08-90-01-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:9 m

Weight :2.907 kg

Views:75

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-02-08-90-01-00 3300 XL 8 mm Proximity Probe is a precision monitoring device designed for industrial machinery health monitoring. It forms part of the 3300 XL machinery protection system and is engineered for high reliability and long-term stability in harsh industrial environments. The probe accurately measures the position and vibration of rotating machinery components without physical contact, enabling predictive maintenance and reducing the risk of catastrophic failures.

Product Specifications

| Parameter | Specification |

|---|---|

| Probe Type | 8 mm diameter proximity probe |

| Model Number | 330104-02-08-90-01-00 |

| Measurement Range | Typically 0.1 – 2.5 mm (varies by mounting and target) |

| Operating Temperature | -40°C to 120°C (-40°F to 248°F) |

| Electrical Interface | 3300 XL system compatible |

| Output Signal | AC or DC displacement signal, depending on system configuration |

| Material | Stainless steel probe housing |

| Weight | 2.907 kg |

| Total Length | 9 m |

| Environmental Rating | IP65 or higher (depending on installation) |

Product Applications

-

Vibration monitoring for rotating machinery including turbines, compressors, and generators

-

Shaft displacement and position monitoring

-

Predictive maintenance programs in power plants and manufacturing facilities

-

Integration with Bently Nevada 3300 XL Machinery Protection System

-

Industrial automation systems requiring non-contact proximity sensing

Product Advantages

High Accuracy: Provides precise displacement measurement with minimal error.

Robust Design: Suitable for extreme temperatures and harsh industrial environments.

Non-Contact Measurement: Reduces wear and tear and eliminates mechanical interference.

Seamless Integration: Directly compatible with Bently Nevada 3300 XL system for real-time monitoring.

Flexible Installation: Variety of mounting options to suit diverse machinery layouts.

Reliable Signal Output: Ensures consistent data for predictive maintenance programs.

FAQ

Q1: What is the typical measurement range of the 3300 XL 8 mm probe?

A1: The probe typically measures displacement in the range of 0.1 mm to 2.5 mm, depending on installation and target material.

Q2: Is the probe compatible with other Bently Nevada systems besides 3300 XL?

A2: It is optimized for the 3300 XL system. Compatibility with older systems may require interface adjustments.

Q3: Can the probe operate in high-temperature environments?

A3: Yes, the operating temperature range is -40°C to 120°C.

Q4: What type of signal output does this probe provide?

A4: It provides AC or DC displacement signals depending on system configuration.

Q5: Can this probe detect both radial and axial displacement?

A5: Primarily radial displacement is measured; axial displacement may require specific mounting configurations.

Q6: What is the recommended cable length for standard installations?

A6: The standard cable length is 1 m, with longer options available upon request.

Q7: Is the probe suitable for explosive or hazardous areas?

A7: It can be installed in hazardous areas if used with proper explosion-proof junctions and housings as per industry standards.

Q8: How does the probe handle high vibration environments?

A8: The probe is designed with robust housing and stable signal processing, minimizing signal interference from external vibration.

Q9: What material is the probe housing made of?

A9: The housing is made of stainless steel for durability and corrosion resistance.

Q10: Can the probe be recalibrated in the field?

A10: Yes, field recalibration is possible using the 3300 XL system calibration tools.

Bently Nevada 330104-02-08-90-01-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-02-08-90-01-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:9 m

Weight :2.907 kg

Views:75

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-02-08-90-01-00 3300 XL 8 mm Proximity Probe is a precision monitoring device designed for industrial machinery health monitoring. It forms part of the 3300 XL machinery protection system and is engineered for high reliability and long-term stability in harsh industrial environments. The probe accurately measures the position and vibration of rotating machinery components without physical contact, enabling predictive maintenance and reducing the risk of catastrophic failures.

Product Specifications

| Parameter | Specification |

|---|---|

| Probe Type | 8 mm diameter proximity probe |

| Model Number | 330104-02-08-90-01-00 |

| Measurement Range | Typically 0.1 – 2.5 mm (varies by mounting and target) |

| Operating Temperature | -40°C to 120°C (-40°F to 248°F) |

| Electrical Interface | 3300 XL system compatible |

| Output Signal | AC or DC displacement signal, depending on system configuration |

| Material | Stainless steel probe housing |

| Weight | 2.907 kg |

| Total Length | 9 m |

| Environmental Rating | IP65 or higher (depending on installation) |

Product Applications

-

Vibration monitoring for rotating machinery including turbines, compressors, and generators

-

Shaft displacement and position monitoring

-

Predictive maintenance programs in power plants and manufacturing facilities

-

Integration with Bently Nevada 3300 XL Machinery Protection System

-

Industrial automation systems requiring non-contact proximity sensing

Product Advantages

High Accuracy: Provides precise displacement measurement with minimal error.

Robust Design: Suitable for extreme temperatures and harsh industrial environments.

Non-Contact Measurement: Reduces wear and tear and eliminates mechanical interference.

Seamless Integration: Directly compatible with Bently Nevada 3300 XL system for real-time monitoring.

Flexible Installation: Variety of mounting options to suit diverse machinery layouts.

Reliable Signal Output: Ensures consistent data for predictive maintenance programs.

FAQ

Q1: What is the typical measurement range of the 3300 XL 8 mm probe?

A1: The probe typically measures displacement in the range of 0.1 mm to 2.5 mm, depending on installation and target material.

Q2: Is the probe compatible with other Bently Nevada systems besides 3300 XL?

A2: It is optimized for the 3300 XL system. Compatibility with older systems may require interface adjustments.

Q3: Can the probe operate in high-temperature environments?

A3: Yes, the operating temperature range is -40°C to 120°C.

Q4: What type of signal output does this probe provide?

A4: It provides AC or DC displacement signals depending on system configuration.

Q5: Can this probe detect both radial and axial displacement?

A5: Primarily radial displacement is measured; axial displacement may require specific mounting configurations.

Q6: What is the recommended cable length for standard installations?

A6: The standard cable length is 1 m, with longer options available upon request.

Q7: Is the probe suitable for explosive or hazardous areas?

A7: It can be installed in hazardous areas if used with proper explosion-proof junctions and housings as per industry standards.

Q8: How does the probe handle high vibration environments?

A8: The probe is designed with robust housing and stable signal processing, minimizing signal interference from external vibration.

Q9: What material is the probe housing made of?

A9: The housing is made of stainless steel for durability and corrosion resistance.

Q10: Can the probe be recalibrated in the field?

A10: Yes, field recalibration is possible using the 3300 XL system calibration tools.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...