Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

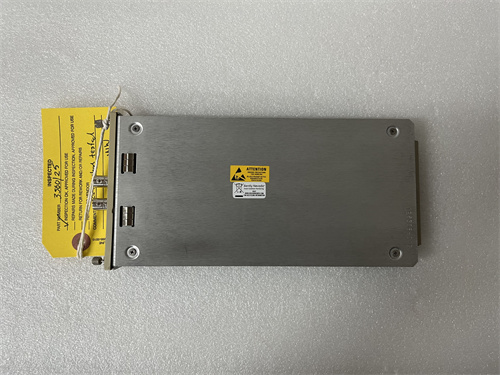

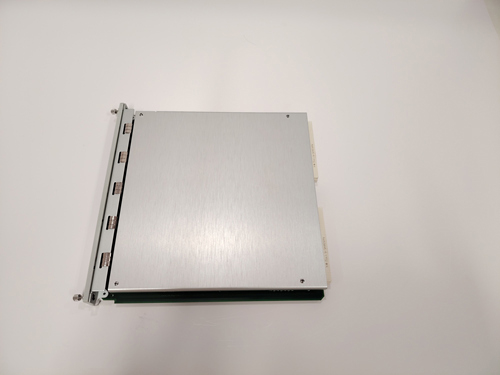

Bently Nevada 330980-50-05 3300 XL NSv Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330980-50-05

Product Type:3300 XL NSv Proximitor Sensor

Origin:USA

Total Length:5.0 meters

Weight:0.255 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330980-50-05 is part of the 3300 XL NSv Proximity Transducer System, specifically designed for monitoring radial vibration, axial position, and speed in compact or tight installation environments such as centrifugal compressors, refrigeration compressors, and process gas compressors. It is ideal for small target measurements, especially where traditional 5 mm or 8 mm systems are too large.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 330980-50-05 |

| System Type | 3300 XL NSv Proximity Transducer System |

| Linear Range | 1.5 mm (60 mils) |

| Scale Factor | 7.87 V/mm (200 mV/mil) |

| Recommended Gap | 1.0 mm (40 mils) |

| Frequency Response | 0 to 10 kHz |

| Operating Temperature | -52°C to +100°C (Proximitor Sensor) |

| Storage Temperature | -52°C to +105°C (Proximitor Sensor) |

| Probe Material | AISI 304 stainless steel, PPS tip |

| Cable Material | FEP-insulated 75 Ω coaxial |

| Sensor Material | A380 Aluminum |

| Total Length | 5.0 meters |

| Weight | 0.255 kg |

| Compliance | CE, RoHS, FCC Part 15, SIL2/SIL3, ATEX, IECEx, cNRTLus |

| Mounting | Panel Mount |

| Protection | IP54 when installed with mounting pad |

Applications

-

Radial vibration and position monitoring for small diameter shafts

-

Axial (thrust) position measurements in turbines and compressors

-

Zero-speed and tachometer signal detection

-

Keyphasor (phase reference) measurements in confined spaces

-

Upgrade paths for 3300 RAM, 3000-series, and 7000-series transducer systems

Advantages

-

Compact design suitable for tight installation spaces

-

Superior side-view performance for small shafts and reduced clearances

-

Chemical-resistant probe and robust construction

-

EMI/RFI shielding for reliable performance in industrial environments

-

SpringLoc terminals for easy wiring and maintenance

-

Fully compatible with DIN rail and panel mounting options

-

Gold-plated ClickLoc connectors ensure secure, durable connectivity

-

Supports long cable runs (up to 305 meters between sensor and monitor)

Frequently Asked Questions (FAQ)

Q1: What is the ideal application for the 330980-50-05 Proximitor Sensor?

A1: It’s best used in compressors or turbines with small shaft diameters or tight mounting spaces.

Q2: What target material is the sensor calibrated to?

A2: AISI 4140 steel is the default calibration material.

Q3: Can it be used in hazardous environments?

A3: Yes, it complies with ATEX, IECEx, and North American hazardous area standards.

Q4: What is the linear measuring range?

A4: The linear range is 1.5 mm (60 mils).

Q5: Is the Proximitor Sensor resistant to EMI and RFI?

A5: Yes, it offers enhanced immunity and CE certification without special mounting.

Q6: How is the wiring done?

A6: It uses SpringLoc terminals with no special tools required, and supports triad shielded cables.

Q7: What is the weight of the complete 5.0-meter system?

A7: Approximately 0.255 kg.

Q8: Are the probe and extension cable interchangeable with older systems?

A8: Yes, with 3300 RAM systems. Not with 3000/7000 series—those require full replacement.

Q9: Does it support panel and DIN rail mounting?

A9: Yes, both options are available.

Q10: What torque should be used on the probe connectors?

A10: Maximum recommended torque is 5 in-lb for sensor connectors.

Bently Nevada 330980-50-05 3300 XL NSv Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330980-50-05

Product Type:3300 XL NSv Proximitor Sensor

Origin:USA

Total Length:5.0 meters

Weight:0.255 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330980-50-05 is part of the 3300 XL NSv Proximity Transducer System, specifically designed for monitoring radial vibration, axial position, and speed in compact or tight installation environments such as centrifugal compressors, refrigeration compressors, and process gas compressors. It is ideal for small target measurements, especially where traditional 5 mm or 8 mm systems are too large.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 330980-50-05 |

| System Type | 3300 XL NSv Proximity Transducer System |

| Linear Range | 1.5 mm (60 mils) |

| Scale Factor | 7.87 V/mm (200 mV/mil) |

| Recommended Gap | 1.0 mm (40 mils) |

| Frequency Response | 0 to 10 kHz |

| Operating Temperature | -52°C to +100°C (Proximitor Sensor) |

| Storage Temperature | -52°C to +105°C (Proximitor Sensor) |

| Probe Material | AISI 304 stainless steel, PPS tip |

| Cable Material | FEP-insulated 75 Ω coaxial |

| Sensor Material | A380 Aluminum |

| Total Length | 5.0 meters |

| Weight | 0.255 kg |

| Compliance | CE, RoHS, FCC Part 15, SIL2/SIL3, ATEX, IECEx, cNRTLus |

| Mounting | Panel Mount |

| Protection | IP54 when installed with mounting pad |

Applications

-

Radial vibration and position monitoring for small diameter shafts

-

Axial (thrust) position measurements in turbines and compressors

-

Zero-speed and tachometer signal detection

-

Keyphasor (phase reference) measurements in confined spaces

-

Upgrade paths for 3300 RAM, 3000-series, and 7000-series transducer systems

Advantages

-

Compact design suitable for tight installation spaces

-

Superior side-view performance for small shafts and reduced clearances

-

Chemical-resistant probe and robust construction

-

EMI/RFI shielding for reliable performance in industrial environments

-

SpringLoc terminals for easy wiring and maintenance

-

Fully compatible with DIN rail and panel mounting options

-

Gold-plated ClickLoc connectors ensure secure, durable connectivity

-

Supports long cable runs (up to 305 meters between sensor and monitor)

Frequently Asked Questions (FAQ)

Q1: What is the ideal application for the 330980-50-05 Proximitor Sensor?

A1: It’s best used in compressors or turbines with small shaft diameters or tight mounting spaces.

Q2: What target material is the sensor calibrated to?

A2: AISI 4140 steel is the default calibration material.

Q3: Can it be used in hazardous environments?

A3: Yes, it complies with ATEX, IECEx, and North American hazardous area standards.

Q4: What is the linear measuring range?

A4: The linear range is 1.5 mm (60 mils).

Q5: Is the Proximitor Sensor resistant to EMI and RFI?

A5: Yes, it offers enhanced immunity and CE certification without special mounting.

Q6: How is the wiring done?

A6: It uses SpringLoc terminals with no special tools required, and supports triad shielded cables.

Q7: What is the weight of the complete 5.0-meter system?

A7: Approximately 0.255 kg.

Q8: Are the probe and extension cable interchangeable with older systems?

A8: Yes, with 3300 RAM systems. Not with 3000/7000 series—those require full replacement.

Q9: Does it support panel and DIN rail mounting?

A9: Yes, both options are available.

Q10: What torque should be used on the probe connectors?

A10: Maximum recommended torque is 5 in-lb for sensor connectors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...