Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

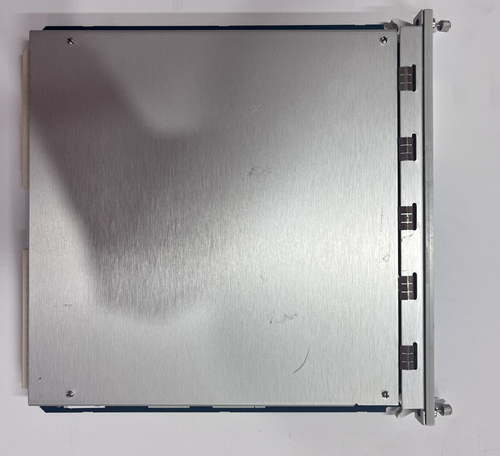

Bently Nevada 176449-04 3500/45 Position Monitor

Brand: Bently Nevada

Model Number: 176449-04

Part Number: 3500/45

Type: Position Monitor

Product Origin: United States

Payment: T/T, Western Union, Credit Card

Dimensions: 19.05 x 12.7 x 8.89 cm (7.5 x 5 x 3.5 in)

Weight: 1.36 kg (3 lb)

Certificate: CE, UL, CSA

Warranty: 1 year

Product Description

The Bently Nevada 176449-04 3500/45 Position Monitor is a 4-channel instrument that accepts input from proximity transducers, Rotary Position Transducers (RPTs), DC Linear Variable Differential Transformers (DC LVDTs), AC Linear Variable Differential Transformers (AC LVDTs), and rotary potentiometers. The monitor conditions the input and compares the conditioned signals with user-programmable alarms.

You can program each channel using the 3500 Rack Configuration Software to perform the following functions:

- Axial (thrust) Position

- Differential Expansion

- Standard Single Ramp Differential Expansion

- Non-standard Single Ramp Differential Expansion

- Dual Ramp Differential Expansion

- Complementary Differential Expansion

- Case Expansion

- Valve Position

The monitor channels are programmed in pairs and can perform up to two of these functions at a time. For example, Channels 1 and 2 can perform one function while channels 3 and 4 may perform the same or a different function.

The primary purpose of the 3500/45 Position Monitor is to provide the following:

- Machinery protection by continuously comparing monitored parameters against configured alarm setpoints to drive alarms.

- Essential machine information for operations and maintenance personnel.

Each channel, depending on configuration, typically conditions its input signal to generate various parameters called measured variables. You can establish alert setpoints for each active measured variable and danger setpoints for any two of the active measured variables.

Technical Specifications

- Vibration measurement range: 0.01 to 1000 Hz

- Accuracy: ±0.25% of reading

- Temperature range: -40 to 85°C

- Power supply: 12 to 36 VDC

- Dimensions: 100 x 70 x 40 mm

- Weight: 0.2 kg

FAQs

Q: What is the operating temperature range of the Bently Nevada 176449-04 3500/45 Position Monitor PLC Module?

A: The operating temperature range of the module is -40°C to 70°C.

Q: What is the input voltage for the Bently Nevada 176449-04 3500/45 Position Monitor PLC Module?

A: The input voltage for the module is 24 VDC nominal.

Q: What is the weight and dimensions of the Bently Nevada 176449-04 3500/45 Position Monitor PLC Module?

A: The weight of the module is 0.4 lbs (0.18 kg) and the dimensions are 4.4 x 3.6 x 1.1 in (11.2 x 9.1 x 2.8 cm).

Q: What is the power consumption and power supply for the Bently Nevada 176449-04 3500/45 Position Monitor PLC Module?

A: The power consumption of the module is 3.4 W and the power supply is 125 VDC nominal.

Bently Nevada 176449-04 3500/45 Position Monitor

Brand: Bently Nevada

Model Number: 176449-04

Part Number: 3500/45

Type: Position Monitor

Product Origin: United States

Payment: T/T, Western Union, Credit Card

Dimensions: 19.05 x 12.7 x 8.89 cm (7.5 x 5 x 3.5 in)

Weight: 1.36 kg (3 lb)

Certificate: CE, UL, CSA

Warranty: 1 year

Product Description

The Bently Nevada 176449-04 3500/45 Position Monitor is a 4-channel instrument that accepts input from proximity transducers, Rotary Position Transducers (RPTs), DC Linear Variable Differential Transformers (DC LVDTs), AC Linear Variable Differential Transformers (AC LVDTs), and rotary potentiometers. The monitor conditions the input and compares the conditioned signals with user-programmable alarms.

You can program each channel using the 3500 Rack Configuration Software to perform the following functions:

- Axial (thrust) Position

- Differential Expansion

- Standard Single Ramp Differential Expansion

- Non-standard Single Ramp Differential Expansion

- Dual Ramp Differential Expansion

- Complementary Differential Expansion

- Case Expansion

- Valve Position

The monitor channels are programmed in pairs and can perform up to two of these functions at a time. For example, Channels 1 and 2 can perform one function while channels 3 and 4 may perform the same or a different function.

The primary purpose of the 3500/45 Position Monitor is to provide the following:

- Machinery protection by continuously comparing monitored parameters against configured alarm setpoints to drive alarms.

- Essential machine information for operations and maintenance personnel.

Each channel, depending on configuration, typically conditions its input signal to generate various parameters called measured variables. You can establish alert setpoints for each active measured variable and danger setpoints for any two of the active measured variables.

Technical Specifications

- Vibration measurement range: 0.01 to 1000 Hz

- Accuracy: ±0.25% of reading

- Temperature range: -40 to 85°C

- Power supply: 12 to 36 VDC

- Dimensions: 100 x 70 x 40 mm

- Weight: 0.2 kg

FAQs

Q: What is the operating temperature range of the Bently Nevada 176449-04 3500/45 Position Monitor PLC Module?

A: The operating temperature range of the module is -40°C to 70°C.

Q: What is the input voltage for the Bently Nevada 176449-04 3500/45 Position Monitor PLC Module?

A: The input voltage for the module is 24 VDC nominal.

Q: What is the weight and dimensions of the Bently Nevada 176449-04 3500/45 Position Monitor PLC Module?

A: The weight of the module is 0.4 lbs (0.18 kg) and the dimensions are 4.4 x 3.6 x 1.1 in (11.2 x 9.1 x 2.8 cm).

Q: What is the power consumption and power supply for the Bently Nevada 176449-04 3500/45 Position Monitor PLC Module?

A: The power consumption of the module is 3.4 W and the power supply is 125 VDC nominal.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...