Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

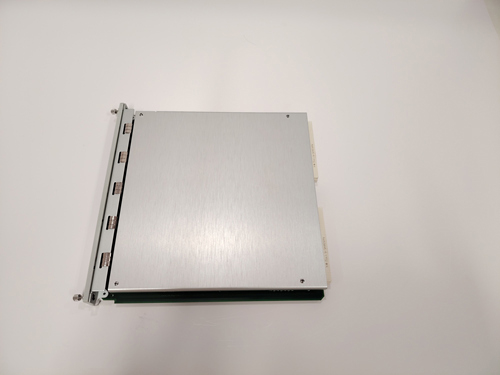

Bently Nevada 330101-00-22-05-02-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-22-05-02-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:0.5 meter

Weight:0.162 kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-22-05-02-05 3300 XL 8mm Proximity Probe is part of the widely respected 3300 XL series of displacement sensors. These probes are designed to provide precise and reliable measurements for machinery vibration monitoring, particularly in environments where rotating equipment is involved. The 3300 XL proximity probes use advanced technology to detect minute shifts in position and vibration, which makes them ideal for condition monitoring applications.

They are highly accurate and offer superior performance for a range of industrial sectors, including oil & gas, power generation, and manufacturing. When used in conjunction with Bently Nevada’s monitoring systems, these probes provide real-time data on the health and condition of machinery, ensuring a proactive approach to maintenance and preventing costly breakdowns.

Product Specifications

| Feature | Details |

|---|---|

| Model | 3300 XL 8mm Proximity Probe |

| Probe Length | 120 mm (4.72 inches) |

| Diameter | 8 mm |

| Sensing Range | 0.4 mm to 50 mm |

| Accuracy | ± 0.1 µm |

| Material | Stainless steel |

| Operating Temperature Range | -40°C to +85°C |

| Weight | 0.162 kg |

| Signal Type | Analog (4-20 mA) or Digital |

| Mounting Type | Direct mounting on machinery shaft |

Product Applications

The Bently Nevada 3300 XL 8mm Proximity Probe is primarily used in industrial machinery condition monitoring systems, providing accurate displacement and vibration measurements. Key applications include:

Rotating Equipment Monitoring: This includes motors, turbines, pumps, and compressors where vibration or position changes are critical indicators of potential failure.

Condition-Based Maintenance: In industries like power generation, oil and gas, and manufacturing, the probes help detect early signs of wear, misalignment, imbalance, or other issues that can lead to equipment failure.

Predictive Maintenance: Proactively monitor machinery health to schedule maintenance before a failure occurs, reducing downtime and operational costs.

Critical Asset Monitoring: High-value assets or equipment requiring high precision in monitoring, ensuring reliability and safety.

Product Advantages

High Precision and Accuracy: The 3300 XL 8mm Proximity Probe offers exceptional measurement accuracy, making it a reliable choice for industries where precision is paramount.

Durability: Built with robust stainless steel housing, these probes are designed to withstand harsh industrial environments, including extreme temperatures, vibration, and exposure to corrosive substances.

Easy Integration: Designed to integrate seamlessly with Bently Nevada’s monitoring systems, allowing users to easily incorporate the probe into their existing infrastructure.

Real-time Data: Provides real-time feedback to operators and engineers, enabling quick decisions on maintenance and operational adjustments.

Flexible Sensing Range: The broad sensing range allows the probe to be used in various applications, from small machines to large turbines, without compromising measurement quality.

FAQs

What is the purpose of the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The probe is used for measuring displacement and vibration in rotating machinery, aiding in condition monitoring to prevent unplanned downtime.

-

Can the 3300 XL Proximity Probe be used in extreme temperatures?

-

Yes, the probe is designed to operate in temperatures ranging from -40°C to +85°C, making it suitable for challenging environments.

-

What is the accuracy of the 3300 XL Proximity Probe?

-

The probe offers a high degree of accuracy, with a tolerance of ±0.1 µm, ensuring reliable and precise readings.

-

What type of signal does the 3300 XL Proximity Probe output?

-

The probe provides either an analog (4-20 mA) or digital signal, depending on the configuration and system requirements.

-

How is the Bently Nevada 3300 XL 8mm Proximity Probe mounted?

-

It can be directly mounted on machinery shafts using a standard mounting bracket.

-

Is the probe suitable for hazardous environments?

-

Yes, the probe is designed to withstand harsh industrial conditions, including exposure to vibration and potential chemical exposure.

-

What types of equipment can the 3300 XL Proximity Probe monitor?

-

It is ideal for monitoring a range of rotating equipment, including motors, pumps, turbines, and compressors.

-

Does the 3300 XL 8mm Proximity Probe require special calibration?

-

Yes, like any precision measuring equipment, the probe may require periodic calibration to maintain its high level of accuracy.

-

Can the Bently Nevada 3300 XL Proximity Probe be used in explosive environments?

-

While the probe is built for robust environments, check with Bently Nevada or review its certification for use in explosive or hazardous environments.

-

How does this probe help in predictive maintenance?

-

By monitoring displacement and vibration in real time, the probe helps identify early signs of equipment failure, allowing for timely maintenance and minimizing unplanned downtime.

-

Bently Nevada 330101-00-22-05-02-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-22-05-02-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:0.5 meter

Weight:0.162 kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-22-05-02-05 3300 XL 8mm Proximity Probe is part of the widely respected 3300 XL series of displacement sensors. These probes are designed to provide precise and reliable measurements for machinery vibration monitoring, particularly in environments where rotating equipment is involved. The 3300 XL proximity probes use advanced technology to detect minute shifts in position and vibration, which makes them ideal for condition monitoring applications.

They are highly accurate and offer superior performance for a range of industrial sectors, including oil & gas, power generation, and manufacturing. When used in conjunction with Bently Nevada’s monitoring systems, these probes provide real-time data on the health and condition of machinery, ensuring a proactive approach to maintenance and preventing costly breakdowns.

Product Specifications

| Feature | Details |

|---|---|

| Model | 3300 XL 8mm Proximity Probe |

| Probe Length | 120 mm (4.72 inches) |

| Diameter | 8 mm |

| Sensing Range | 0.4 mm to 50 mm |

| Accuracy | ± 0.1 µm |

| Material | Stainless steel |

| Operating Temperature Range | -40°C to +85°C |

| Weight | 0.162 kg |

| Signal Type | Analog (4-20 mA) or Digital |

| Mounting Type | Direct mounting on machinery shaft |

Product Applications

The Bently Nevada 3300 XL 8mm Proximity Probe is primarily used in industrial machinery condition monitoring systems, providing accurate displacement and vibration measurements. Key applications include:

Rotating Equipment Monitoring: This includes motors, turbines, pumps, and compressors where vibration or position changes are critical indicators of potential failure.

Condition-Based Maintenance: In industries like power generation, oil and gas, and manufacturing, the probes help detect early signs of wear, misalignment, imbalance, or other issues that can lead to equipment failure.

Predictive Maintenance: Proactively monitor machinery health to schedule maintenance before a failure occurs, reducing downtime and operational costs.

Critical Asset Monitoring: High-value assets or equipment requiring high precision in monitoring, ensuring reliability and safety.

Product Advantages

High Precision and Accuracy: The 3300 XL 8mm Proximity Probe offers exceptional measurement accuracy, making it a reliable choice for industries where precision is paramount.

Durability: Built with robust stainless steel housing, these probes are designed to withstand harsh industrial environments, including extreme temperatures, vibration, and exposure to corrosive substances.

Easy Integration: Designed to integrate seamlessly with Bently Nevada’s monitoring systems, allowing users to easily incorporate the probe into their existing infrastructure.

Real-time Data: Provides real-time feedback to operators and engineers, enabling quick decisions on maintenance and operational adjustments.

Flexible Sensing Range: The broad sensing range allows the probe to be used in various applications, from small machines to large turbines, without compromising measurement quality.

FAQs

What is the purpose of the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The probe is used for measuring displacement and vibration in rotating machinery, aiding in condition monitoring to prevent unplanned downtime.

-

Can the 3300 XL Proximity Probe be used in extreme temperatures?

-

Yes, the probe is designed to operate in temperatures ranging from -40°C to +85°C, making it suitable for challenging environments.

-

What is the accuracy of the 3300 XL Proximity Probe?

-

The probe offers a high degree of accuracy, with a tolerance of ±0.1 µm, ensuring reliable and precise readings.

-

What type of signal does the 3300 XL Proximity Probe output?

-

The probe provides either an analog (4-20 mA) or digital signal, depending on the configuration and system requirements.

-

How is the Bently Nevada 3300 XL 8mm Proximity Probe mounted?

-

It can be directly mounted on machinery shafts using a standard mounting bracket.

-

Is the probe suitable for hazardous environments?

-

Yes, the probe is designed to withstand harsh industrial conditions, including exposure to vibration and potential chemical exposure.

-

What types of equipment can the 3300 XL Proximity Probe monitor?

-

It is ideal for monitoring a range of rotating equipment, including motors, pumps, turbines, and compressors.

-

Does the 3300 XL 8mm Proximity Probe require special calibration?

-

Yes, like any precision measuring equipment, the probe may require periodic calibration to maintain its high level of accuracy.

-

Can the Bently Nevada 3300 XL Proximity Probe be used in explosive environments?

-

While the probe is built for robust environments, check with Bently Nevada or review its certification for use in explosive or hazardous environments.

-

How does this probe help in predictive maintenance?

-

By monitoring displacement and vibration in real time, the probe helps identify early signs of equipment failure, allowing for timely maintenance and minimizing unplanned downtime.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...