Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

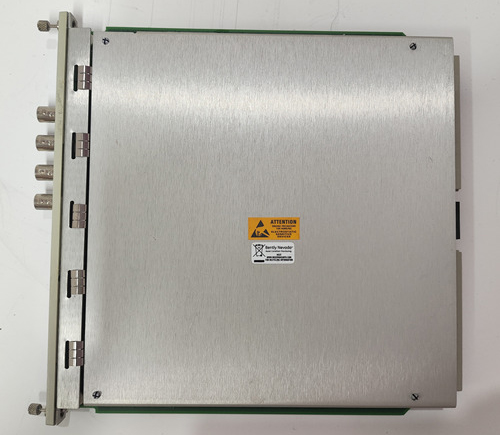

Bently Nevada 330101-00-40-10-02-00 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-40-10-02-00

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-40-10-02-00 is a premium non-contact proximity probe designed for precise measurement of shaft vibration and position in rotating machinery. Manufactured by Bently Nevada, a part of Baker Hughes, this model is a key component in the 3300 XL 8mm series—engineered specifically for applications requiring API 670 compliance and high-reliability performance in industrial environments.

This particular model features a 40-inch unarmored probe with a 1.0 meter integral coaxial cable, designed to connect directly to a 3300 XL Proximitor® Sensor. It provides superior linearity, sensitivity, and environmental resistance, making it ideal for monitoring critical machinery such as turbines, compressors, and large motors.

The 330101-00-40-10-02-00 is part of a fully modular system, which includes the probe, extension cable, and Proximitor sensor—each of which can be replaced independently.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-40-10-02-00 |

| Series | 3300 XL 8mm Proximity Probe System |

| Sensing Tip Diameter | 8 mm |

| Probe Length | 40 inches (1016 mm) |

| Total Length | 1.0 meter |

| Cable Type | Unarmored coaxial cable |

| Thread Type | 3/8-24 UNF-2A |

| Sensing Range | 2 mm (80 mils) nominal |

| Linear Range | 0.5 mm to 2.0 mm (20 to 80 mils) |

| Sensitivity | 200 mV/mil (7.87 mV/μm) ±5% |

| Accuracy | ±0.07 mm (±2.8 mils) typical |

| Temperature Range | -35°C to +177°C (Operating) |

| Pressure Rating | Up to 10,000 psi (with sealed housing) |

| Material (Body) | AISI 303 stainless steel |

| Connector Type | Coaxial mini-connector (for Proximitor sensor connection) |

| IP Rating | IP65 (at sensing tip) |

| Compliance | Fully API 670 compliant |

| Weight | 0.323 kg |

Product Applications

The 330101-00-40-10-02-00 proximity probe is widely used for non-contact dynamic and static measurements in rotating machinery and critical asset monitoring. It supports:

Shaft radial vibration measurement

Axial (thrust) position monitoring

Rotor speed via Keyphasor® systems

Rotor-to-stator clearance detection

Runout, eccentricity, and thermal expansion monitoring

Common applications include:

-

Steam and gas turbines

-

Axial and centrifugal compressors

-

Large industrial motors and generators

-

Paper mill roll sections

-

Gearboxes and high-speed couplings

-

Marine propulsion systems

Product Advantages

Extended Reach: probe offers excellent accessibility for deep or complex installations.

Stable Measurement Output: Maintains consistent output across varying temperatures and operating conditions.

Field-Proven Durability: Stainless steel body resists corrosion, vibration, and chemical exposure.

Excellent Compatibility: Integrates seamlessly with 3300 XL Proximitor Sensors and the Bently Nevada 3500 system.

High Linear Accuracy: Delivers reliable performance with industry-standard sensitivity of 200 mV/mil.

Global Compliance: Built in accordance with API 670 for machine protection standards.

Modular Architecture: Probe, cable, and Proximitor sensor are independently serviceable and replaceable.

Environmental Resistance: Designed for harsh operating environments, including high-pressure and high-temperature areas.

Low Installation Complexity: Threaded body and pre-terminated cable simplify the setup process.

Reliable Signal Integrity: Coaxial construction ensures minimal noise and signal distortion.

Frequently Asked Questions (FAQ)

Q: What does the “10” in the model number represent?

A: It refers to the 1.0 meter Total Length, ideal for reaching deep machinery shafts.

Q: What is the function of this proximity probe?

A: It measures shaft position and vibration in critical rotating machinery, without physical contact.

Q: Is this model armored?

A: No, this version comes with a 1.0 meter unarmored coaxial cable.

Q: What temperature can this probe tolerate?

A: It operates reliably from -35°C to +177°C.

Q: Is this model compatible with the 3300 XL Proximitor?

A: Yes, it’s specifically designed for integration with the 3300 XL Proximitor Sensor.

Q: Can it be used in hazardous environments?

A: Yes, when used with appropriate housings and compliant accessories, it can be installed in hazardous zones.

Q: How accurate is the probe?

A: It typically provides an accuracy of ±0.07 mm, depending on system configuration.

Q: Does it meet API 670 compliance?

A: Yes, it meets or exceeds the API 670 standard for machinery protection systems.

Q: What equipment can this be installed on?

A: It’s suitable for turbines, compressors, motors, generators, and other critical rotating equipment.

Q: Can the probe be replaced separately from the rest of the system?

A: Yes, the probe, extension cable, and Proximitor sensor are modular and replaceable independently.

Bently Nevada 330101-00-40-10-02-00 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-40-10-02-00

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-40-10-02-00 is a premium non-contact proximity probe designed for precise measurement of shaft vibration and position in rotating machinery. Manufactured by Bently Nevada, a part of Baker Hughes, this model is a key component in the 3300 XL 8mm series—engineered specifically for applications requiring API 670 compliance and high-reliability performance in industrial environments.

This particular model features a 40-inch unarmored probe with a 1.0 meter integral coaxial cable, designed to connect directly to a 3300 XL Proximitor® Sensor. It provides superior linearity, sensitivity, and environmental resistance, making it ideal for monitoring critical machinery such as turbines, compressors, and large motors.

The 330101-00-40-10-02-00 is part of a fully modular system, which includes the probe, extension cable, and Proximitor sensor—each of which can be replaced independently.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-40-10-02-00 |

| Series | 3300 XL 8mm Proximity Probe System |

| Sensing Tip Diameter | 8 mm |

| Probe Length | 40 inches (1016 mm) |

| Total Length | 1.0 meter |

| Cable Type | Unarmored coaxial cable |

| Thread Type | 3/8-24 UNF-2A |

| Sensing Range | 2 mm (80 mils) nominal |

| Linear Range | 0.5 mm to 2.0 mm (20 to 80 mils) |

| Sensitivity | 200 mV/mil (7.87 mV/μm) ±5% |

| Accuracy | ±0.07 mm (±2.8 mils) typical |

| Temperature Range | -35°C to +177°C (Operating) |

| Pressure Rating | Up to 10,000 psi (with sealed housing) |

| Material (Body) | AISI 303 stainless steel |

| Connector Type | Coaxial mini-connector (for Proximitor sensor connection) |

| IP Rating | IP65 (at sensing tip) |

| Compliance | Fully API 670 compliant |

| Weight | 0.323 kg |

Product Applications

The 330101-00-40-10-02-00 proximity probe is widely used for non-contact dynamic and static measurements in rotating machinery and critical asset monitoring. It supports:

Shaft radial vibration measurement

Axial (thrust) position monitoring

Rotor speed via Keyphasor® systems

Rotor-to-stator clearance detection

Runout, eccentricity, and thermal expansion monitoring

Common applications include:

-

Steam and gas turbines

-

Axial and centrifugal compressors

-

Large industrial motors and generators

-

Paper mill roll sections

-

Gearboxes and high-speed couplings

-

Marine propulsion systems

Product Advantages

Extended Reach: probe offers excellent accessibility for deep or complex installations.

Stable Measurement Output: Maintains consistent output across varying temperatures and operating conditions.

Field-Proven Durability: Stainless steel body resists corrosion, vibration, and chemical exposure.

Excellent Compatibility: Integrates seamlessly with 3300 XL Proximitor Sensors and the Bently Nevada 3500 system.

High Linear Accuracy: Delivers reliable performance with industry-standard sensitivity of 200 mV/mil.

Global Compliance: Built in accordance with API 670 for machine protection standards.

Modular Architecture: Probe, cable, and Proximitor sensor are independently serviceable and replaceable.

Environmental Resistance: Designed for harsh operating environments, including high-pressure and high-temperature areas.

Low Installation Complexity: Threaded body and pre-terminated cable simplify the setup process.

Reliable Signal Integrity: Coaxial construction ensures minimal noise and signal distortion.

Frequently Asked Questions (FAQ)

Q: What does the “10” in the model number represent?

A: It refers to the 1.0 meter Total Length, ideal for reaching deep machinery shafts.

Q: What is the function of this proximity probe?

A: It measures shaft position and vibration in critical rotating machinery, without physical contact.

Q: Is this model armored?

A: No, this version comes with a 1.0 meter unarmored coaxial cable.

Q: What temperature can this probe tolerate?

A: It operates reliably from -35°C to +177°C.

Q: Is this model compatible with the 3300 XL Proximitor?

A: Yes, it’s specifically designed for integration with the 3300 XL Proximitor Sensor.

Q: Can it be used in hazardous environments?

A: Yes, when used with appropriate housings and compliant accessories, it can be installed in hazardous zones.

Q: How accurate is the probe?

A: It typically provides an accuracy of ±0.07 mm, depending on system configuration.

Q: Does it meet API 670 compliance?

A: Yes, it meets or exceeds the API 670 standard for machinery protection systems.

Q: What equipment can this be installed on?

A: It’s suitable for turbines, compressors, motors, generators, and other critical rotating equipment.

Q: Can the probe be replaced separately from the rest of the system?

A: Yes, the probe, extension cable, and Proximitor sensor are modular and replaceable independently.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...