Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

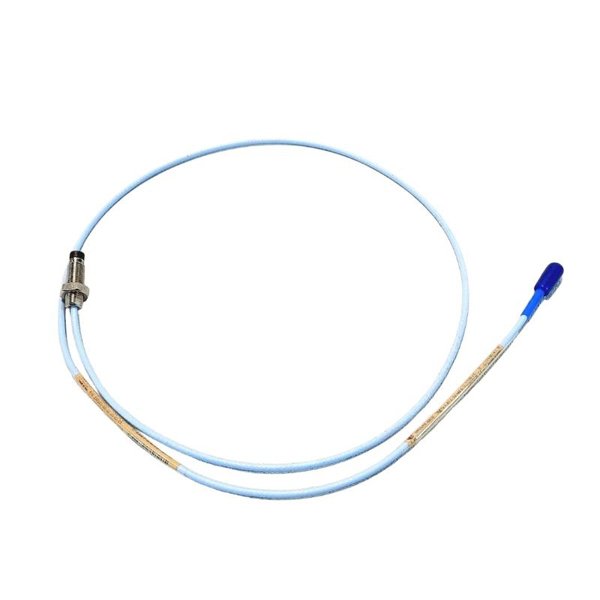

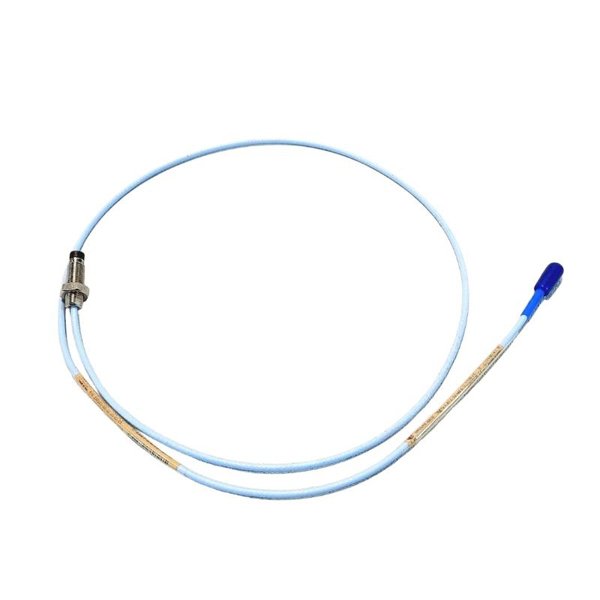

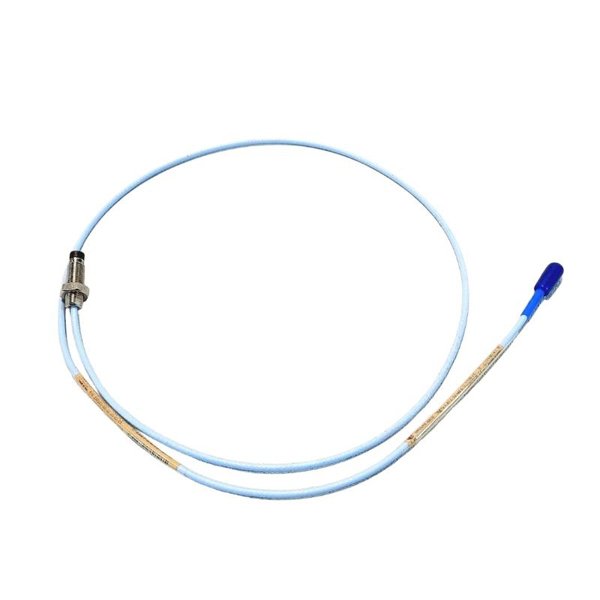

Bently Nevada 330192-10-95-90-CN 3300 XL 8 mm ETR Probe

Manufacturer:Bently Nevada

Product Number:330192-10-95-90-CN

Product Type:3300 XL 8 mm ETR Probe

Origin:USA

Total Length:9 meters

Weight:2.907 kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330192-10-95-90-CN 3300 XL 8 mm ETR Probe is a premium non-contact proximity sensor designed for precise vibration and shaft displacement monitoring in critical rotating machinery. As part of the renowned 3300 XL series, it delivers exceptional accuracy and long-term stability under harsh industrial conditions. The probe works seamlessly with Bently Nevada Proximitor® sensors to provide reliable, real-time data for predictive maintenance and protection of turbines, compressors, motors, and other high-speed equipment.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330192-10-95-90-CN |

| Probe Type | 3300 XL 8 mm ETR (Extended Temperature Range) |

| Measurement Range | 2 mm (80 mil) linear range |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Tip Diameter | 8 mm |

| Thread Type | M10 × 1 mm |

| Operating Temperature (Probe) | –35 °C to +200 °C |

| Operating Temperature (Cable/Connector) | –51 °C to +177 °C |

| Frequency Range | 0 to 10 kHz |

| Vibration Tolerance | Up to 20 g, 10–2000 Hz |

| Shock Tolerance | Up to 200 g peak |

| Environmental Protection | IP67 |

| Total Length | 9 meters |

| Weight | 2.907 kg |

Product Applications

Turbomachinery: Accurate monitoring of rotor position and shaft vibration in gas and steam turbines.

Compressors and Pumps: Detects imbalance and bearing wear for early maintenance action.

Generators and Motors: Provides continuous vibration diagnostics for critical rotating components.

Petrochemical and Power Plants: Ensures precise displacement measurement in high-temperature or corrosive environments.

Product Advantages

High Measurement Precision: Offers a stable linear response with 7.87 mV/µm sensitivity.

Extended Temperature Range: Maintains accuracy from –35 °C to +200 °C in the probe and down to –51 °C in cabling.

Durable Construction: IP67-rated housing protects against dust, moisture, and industrial contaminants.

Seamless System Integration: Fully compatible with Bently Nevada 3300 XL Proximitor® monitoring systems.

Outstanding Signal Integrity: Shielded design reduces electromagnetic interference, ensuring reliable long-term data.

Shock and Vibration Resistance: Engineered to withstand high mechanical shock and continuous vibration.

FAQ

What is the specified sensitivity of this probe?

It provides a nominal sensitivity of 7.87 mV/µm (200 mV/mil) to ensure accurate proximity and vibration measurements.

Which Bently Nevada systems support this probe?

It integrates directly with 3300 XL Proximitor® sensors and related monitoring systems for easy deployment.

What is the operating temperature capability of the probe and cable assembly?

The probe operates between –35 °C and +200 °C, while the cable and connector function from –51 °C to +177 °C.

How is this probe mounted for optimal performance?

The probe uses an M10 × 1 mm threaded body with a locknut to achieve secure installation and consistent gap control.

What sensing principle does the probe use?

It employs eddy-current technology to produce a voltage proportional to the distance between the probe tip and the shaft.

What is the vibration limit for continuous operation?

It withstands continuous vibration up to 20 g within a 10–2000 Hz frequency range.

Does it comply with industrial environmental standards?

Yes, it meets IP67 protection standards, offering dust-tight sealing and resistance to water exposure.

What level of mechanical shock can this probe endure?

The assembly is rated for mechanical shocks up to 200 g peak without loss of functionality.

How is signal stability ensured over long-term use?

High-quality shielding and robust materials minimize electromagnetic interference and temperature drift.

Can the probe measure both radial and axial shaft motion?

Yes, it is capable of accurately measuring both radial vibration and axial displacement, enabling comprehensive equipment diagnostics.

Bently Nevada 330192-10-95-90-CN 3300 XL 8 mm ETR Probe

Manufacturer:Bently Nevada

Product Number:330192-10-95-90-CN

Product Type:3300 XL 8 mm ETR Probe

Origin:USA

Total Length:9 meters

Weight:2.907 kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330192-10-95-90-CN 3300 XL 8 mm ETR Probe is a premium non-contact proximity sensor designed for precise vibration and shaft displacement monitoring in critical rotating machinery. As part of the renowned 3300 XL series, it delivers exceptional accuracy and long-term stability under harsh industrial conditions. The probe works seamlessly with Bently Nevada Proximitor® sensors to provide reliable, real-time data for predictive maintenance and protection of turbines, compressors, motors, and other high-speed equipment.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330192-10-95-90-CN |

| Probe Type | 3300 XL 8 mm ETR (Extended Temperature Range) |

| Measurement Range | 2 mm (80 mil) linear range |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Tip Diameter | 8 mm |

| Thread Type | M10 × 1 mm |

| Operating Temperature (Probe) | –35 °C to +200 °C |

| Operating Temperature (Cable/Connector) | –51 °C to +177 °C |

| Frequency Range | 0 to 10 kHz |

| Vibration Tolerance | Up to 20 g, 10–2000 Hz |

| Shock Tolerance | Up to 200 g peak |

| Environmental Protection | IP67 |

| Total Length | 9 meters |

| Weight | 2.907 kg |

Product Applications

Turbomachinery: Accurate monitoring of rotor position and shaft vibration in gas and steam turbines.

Compressors and Pumps: Detects imbalance and bearing wear for early maintenance action.

Generators and Motors: Provides continuous vibration diagnostics for critical rotating components.

Petrochemical and Power Plants: Ensures precise displacement measurement in high-temperature or corrosive environments.

Product Advantages

High Measurement Precision: Offers a stable linear response with 7.87 mV/µm sensitivity.

Extended Temperature Range: Maintains accuracy from –35 °C to +200 °C in the probe and down to –51 °C in cabling.

Durable Construction: IP67-rated housing protects against dust, moisture, and industrial contaminants.

Seamless System Integration: Fully compatible with Bently Nevada 3300 XL Proximitor® monitoring systems.

Outstanding Signal Integrity: Shielded design reduces electromagnetic interference, ensuring reliable long-term data.

Shock and Vibration Resistance: Engineered to withstand high mechanical shock and continuous vibration.

FAQ

What is the specified sensitivity of this probe?

It provides a nominal sensitivity of 7.87 mV/µm (200 mV/mil) to ensure accurate proximity and vibration measurements.

Which Bently Nevada systems support this probe?

It integrates directly with 3300 XL Proximitor® sensors and related monitoring systems for easy deployment.

What is the operating temperature capability of the probe and cable assembly?

The probe operates between –35 °C and +200 °C, while the cable and connector function from –51 °C to +177 °C.

How is this probe mounted for optimal performance?

The probe uses an M10 × 1 mm threaded body with a locknut to achieve secure installation and consistent gap control.

What sensing principle does the probe use?

It employs eddy-current technology to produce a voltage proportional to the distance between the probe tip and the shaft.

What is the vibration limit for continuous operation?

It withstands continuous vibration up to 20 g within a 10–2000 Hz frequency range.

Does it comply with industrial environmental standards?

Yes, it meets IP67 protection standards, offering dust-tight sealing and resistance to water exposure.

What level of mechanical shock can this probe endure?

The assembly is rated for mechanical shocks up to 200 g peak without loss of functionality.

How is signal stability ensured over long-term use?

High-quality shielding and robust materials minimize electromagnetic interference and temperature drift.

Can the probe measure both radial and axial shaft motion?

Yes, it is capable of accurately measuring both radial vibration and axial displacement, enabling comprehensive equipment diagnostics.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...