Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

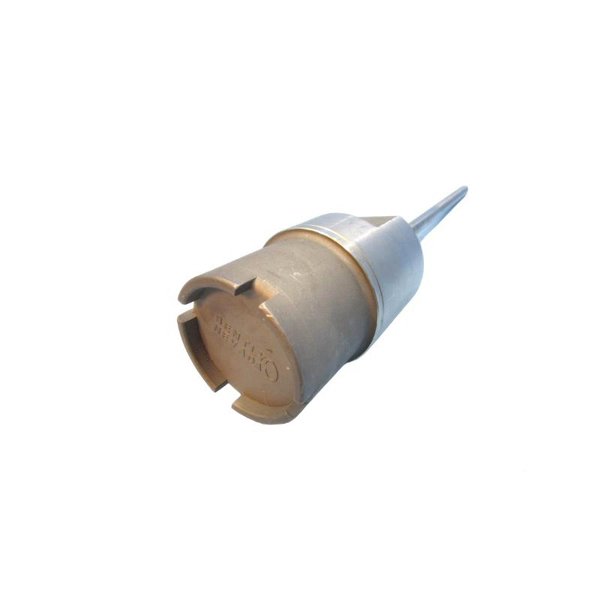

Bently Nevada 21000-16-10-15-114-03-02 Proximity Probe Housing Assemblies

Manufacturer:Bently Nevada

Product Number:21000-16-10-15-114-03-02

Product Type:Proximity Probe Housing Assemblies

Origin:USA

Housing Body Diameter:83.3 mm

Weight:1.1 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 21000-16-10-15-114-03-02 Proximity Probe Housing Assembly is an engineered enclosure designed to provide robust protection and accurate positioning for proximity probes in critical machinery monitoring environments. Part of the renowned 21000 series, this housing features a 3/4-16 UNF thread with a unique configuration optimized for specific industrial installations where precision and durability are essential.

This housing assembly is manufactured using corrosion-resistant 316L stainless steel, providing excellent mechanical strength and long service life even under harsh environmental conditions such as extreme temperatures, vibration, and exposure to corrosive elements. It is compatible with Bently Nevada’s leading proximity probes, supporting reliable shaft displacement and vibration measurement in turbines, compressors, generators, and other high-speed rotating machinery.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 21000-16-10-15-114-03-02 |

| Series | 21000 Series |

| Material | 316L Stainless Steel |

| Thread Type | 3/4-16 UNF |

| Cable Entry | Side-entry sealed conduit fitting |

| Environmental Rating | IP66 / NEMA 4X |

| Operating Temperature Range | -40°C to +177°C (-40°F to +350°F) |

| Vibration Resistance | Up to 50 g |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Sealing System | Dual O-ring and compression gland |

| Internal Wiring Interface | Terminal block for secure field wiring |

| Surface Finish | Electro-polished stainless steel for enhanced corrosion resistance |

| Compatible Probe Series | 3300 XL, 7200, 9000 series |

| Certifications Available | CE, CSA, ATEX (upon request/configuration) |

| Installation Orientation | Supports vertical or horizontal mounting |

Product Applications

The 21000-16-10-15-114-03-02 housing assembly is widely used in demanding industrial environments where accurate vibration and position monitoring is vital:

Gas and Steam Turbines: Reliable probe mounting to detect shaft position and vibration, ensuring machine health.

Centrifugal and Axial Compressors: Maintains sensor stability in high-vibration compressor environments.

Hydroelectric Generators: Provides protection against moisture, dust, and mechanical shock.

Petrochemical Processing Plants: Suitable for use in corrosive and high-temperature process environments.

Marine Propulsion Systems: Durable enough for harsh marine environments, resisting saltwater corrosion.

Industrial Motors and Pumps: Facilitates shaft position monitoring to prevent mechanical failures.

Product Advantages

High-Precision Machining: Guarantees proper probe alignment for accurate measurements.

Robust Environmental Protection: IP66/NEMA 4X rated housing withstands dust, moisture, and chemical exposure.

Corrosion Resistant: Made from 316L stainless steel with an electro-polished finish for longevity.

Flexible Installation: Supports multiple mounting orientations to adapt to equipment layouts.

Vibration Resistance: Designed to endure up to 50 g vibration, maintaining probe stability.

Secure Wiring Interface: Terminal block design simplifies field installation and maintenance.

Hazardous Area Certifications: Optional ATEX, CSA, and CE certifications for use in explosive atmospheres.

Extended Housing Length: Offers additional probe protection in installations requiring deeper sensor positioning.

Frequently Asked Questions (FAQ)

What type of probes fit this housing assembly?

This housing is compatible with Bently Nevada 3300 XL, 7200, and 9000 series proximity probes.

What makes the -114-03-02 variant special?

It has a longer housing length compared to other versions, allowing for deeper installation or angled probe placements.

Is this housing suitable for outdoor use?

Yes, it is rated IP66/NEMA 4X, protecting against water, dust, and corrosive elements.

Does it support hazardous locations?

Yes, it can be configured to meet ATEX, CSA, and CE certifications for use in explosive atmospheres.

What is the housing’s weight?

The assembly weighs 1.1 kg.

Can it be mounted horizontally and vertically?

Yes, the housing is designed for flexible installation orientations.

How does the sealing system prevent moisture intrusion?

It employs dual O-rings and a compression gland to maintain a tight seal against moisture ingress.

Is the surface resistant to corrosion?

Yes, the electro-polished 316L stainless steel resists corrosion in harsh environments.

What is the maximum operating temperature?

It can operate continuously in temperatures up to 177°C (350°F).

Does the housing facilitate easy wiring?

Yes, the built-in terminal block makes wiring installation and maintenance straightforward.

Bently Nevada 21000-16-10-15-114-03-02 Proximity Probe Housing Assemblies

Manufacturer:Bently Nevada

Product Number:21000-16-10-15-114-03-02

Product Type:Proximity Probe Housing Assemblies

Origin:USA

Housing Body Diameter:83.3 mm

Weight:1.1 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 21000-16-10-15-114-03-02 Proximity Probe Housing Assembly is an engineered enclosure designed to provide robust protection and accurate positioning for proximity probes in critical machinery monitoring environments. Part of the renowned 21000 series, this housing features a 3/4-16 UNF thread with a unique configuration optimized for specific industrial installations where precision and durability are essential.

This housing assembly is manufactured using corrosion-resistant 316L stainless steel, providing excellent mechanical strength and long service life even under harsh environmental conditions such as extreme temperatures, vibration, and exposure to corrosive elements. It is compatible with Bently Nevada’s leading proximity probes, supporting reliable shaft displacement and vibration measurement in turbines, compressors, generators, and other high-speed rotating machinery.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 21000-16-10-15-114-03-02 |

| Series | 21000 Series |

| Material | 316L Stainless Steel |

| Thread Type | 3/4-16 UNF |

| Cable Entry | Side-entry sealed conduit fitting |

| Environmental Rating | IP66 / NEMA 4X |

| Operating Temperature Range | -40°C to +177°C (-40°F to +350°F) |

| Vibration Resistance | Up to 50 g |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Sealing System | Dual O-ring and compression gland |

| Internal Wiring Interface | Terminal block for secure field wiring |

| Surface Finish | Electro-polished stainless steel for enhanced corrosion resistance |

| Compatible Probe Series | 3300 XL, 7200, 9000 series |

| Certifications Available | CE, CSA, ATEX (upon request/configuration) |

| Installation Orientation | Supports vertical or horizontal mounting |

Product Applications

The 21000-16-10-15-114-03-02 housing assembly is widely used in demanding industrial environments where accurate vibration and position monitoring is vital:

Gas and Steam Turbines: Reliable probe mounting to detect shaft position and vibration, ensuring machine health.

Centrifugal and Axial Compressors: Maintains sensor stability in high-vibration compressor environments.

Hydroelectric Generators: Provides protection against moisture, dust, and mechanical shock.

Petrochemical Processing Plants: Suitable for use in corrosive and high-temperature process environments.

Marine Propulsion Systems: Durable enough for harsh marine environments, resisting saltwater corrosion.

Industrial Motors and Pumps: Facilitates shaft position monitoring to prevent mechanical failures.

Product Advantages

High-Precision Machining: Guarantees proper probe alignment for accurate measurements.

Robust Environmental Protection: IP66/NEMA 4X rated housing withstands dust, moisture, and chemical exposure.

Corrosion Resistant: Made from 316L stainless steel with an electro-polished finish for longevity.

Flexible Installation: Supports multiple mounting orientations to adapt to equipment layouts.

Vibration Resistance: Designed to endure up to 50 g vibration, maintaining probe stability.

Secure Wiring Interface: Terminal block design simplifies field installation and maintenance.

Hazardous Area Certifications: Optional ATEX, CSA, and CE certifications for use in explosive atmospheres.

Extended Housing Length: Offers additional probe protection in installations requiring deeper sensor positioning.

Frequently Asked Questions (FAQ)

What type of probes fit this housing assembly?

This housing is compatible with Bently Nevada 3300 XL, 7200, and 9000 series proximity probes.

What makes the -114-03-02 variant special?

It has a longer housing length compared to other versions, allowing for deeper installation or angled probe placements.

Is this housing suitable for outdoor use?

Yes, it is rated IP66/NEMA 4X, protecting against water, dust, and corrosive elements.

Does it support hazardous locations?

Yes, it can be configured to meet ATEX, CSA, and CE certifications for use in explosive atmospheres.

What is the housing’s weight?

The assembly weighs 1.1 kg.

Can it be mounted horizontally and vertically?

Yes, the housing is designed for flexible installation orientations.

How does the sealing system prevent moisture intrusion?

It employs dual O-rings and a compression gland to maintain a tight seal against moisture ingress.

Is the surface resistant to corrosion?

Yes, the electro-polished 316L stainless steel resists corrosion in harsh environments.

What is the maximum operating temperature?

It can operate continuously in temperatures up to 177°C (350°F).

Does the housing facilitate easy wiring?

Yes, the built-in terminal block makes wiring installation and maintenance straightforward.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...