Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

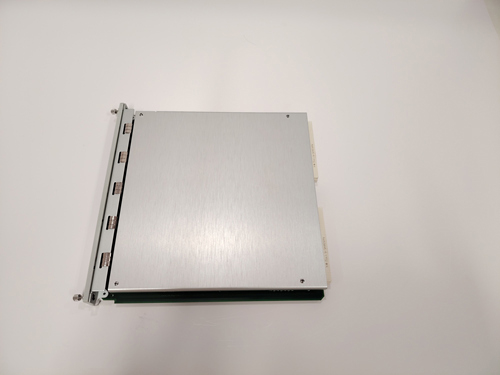

Bently Nevada 3500/05-01-02-02-00-01 3500/05 System Rack

Manufacturer:Bently Nevada

Product Number:3500/05-01-02-02-00-01

Product Type:3500/05 System Rack

Origin:USA

Rack Size:19-inch (14 module slots)

Weight :4.5 kg

Views:30

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/05-01-02-02-00-01 is a component of the Bently Nevada 3500 Machinery Protection System, which is designed for monitoring and protecting industrial machinery. This system is known for its robust performance and is used in various industries to ensure the integrity of critical equipment. The product focuses on vibration monitoring, condition-based maintenance, and advanced diagnostic features to safeguard equipment from potential failures.

The 3500/05-01-02-02-00-01 is a specialized rack for housing Bently Nevada’s machinery protection modules, facilitating the integration of multiple monitoring sensors and devices into a single, centralized unit.

Product Parameters

| Parameter | Details |

|---|---|

| Model | 3500/05-01-02-02-00-01 |

| Rack Size | 19-inch (14 module slots) |

| Weight | 4.5 kg |

| Voltage Input | 85–264V AC |

| Operating Temp | -20°C to 60°C (-4°F to 140°F) |

| Humidity | 5% to 95% RH (non-condensing) |

| Power Consumption | 10W max |

| Mounting | Rack-mounted |

| Certification | CE, UL |

Applications

The Bently Nevada 3500/05-01-02-02-00-01 is used in industrial applications that require continuous monitoring of rotating machinery. Its primary uses include:

Vibration Monitoring – Detects excessive vibration in pumps, motors, turbines, and compressors.

Condition Monitoring – Tracks changes in operating conditions over time for predictive maintenance.

Protective Relaying – Provides automated system shutdowns based on preset alarm thresholds to prevent damage.

Preventive Maintenance – Assists maintenance teams by alerting them to potential mechanical failures before they occur.

Integrated Monitoring Systems – Works with other Bently Nevada products to provide a comprehensive machinery protection solution.

Advantages

Reliability: Known for exceptional durability in harsh industrial environments, the Bently Nevada 3500/05-01-02-02-00-01 is designed to withstand extreme conditions.

Easy Integration: Seamlessly integrates with other components in the Bently Nevada 3500 series, making system expansion straightforward.

Scalable Monitoring: Provides scalable solutions, ideal for both small and large industrial setups.

Advanced Diagnostics: Offers advanced diagnostic capabilities that can detect early signs of mechanical failure, reducing downtime.

Cost-Effective Maintenance: Helps reduce maintenance costs by enabling predictive maintenance rather than reactive repair work.

FAQs

1. What is the purpose of the Bently Nevada 3500/05-01-02-02-00-01?

-

The Bently Nevada 3500/05-01-02-02-00-01 is used as part of a machinery protection system to monitor the condition of critical industrial equipment and prevent catastrophic failures.

2. Can this module be used for any type of machine?

-

Yes, it is designed to monitor various rotating machinery such as turbines, compressors, and motors across multiple industries.

3. How is the unit installed?

-

The unit is rack-mounted and should be installed within a compatible Bently Nevada 3500 system rack.

4. What voltage does this product operate on?

-

The product operates on an AC voltage input range of 85–264V.

5. What is the operating temperature range of this unit?

-

The unit operates in temperatures ranging from -20°C to 60°C (-4°F to 140°F).

6. What type of maintenance is required for this product?

-

The product requires regular checking of sensor connections, as well as monitoring the diagnostic outputs to ensure optimal system performance.

7. Does the Bently Nevada 3500/05-01-02-02-00-01 have any certifications?

-

Yes, it is CE and UL certified for safety and reliability.

8. Can I integrate this with other Bently Nevada products?

-

Yes, it integrates easily with other modules in the Bently Nevada 3500 series, providing a comprehensive machinery monitoring solution.

9. What is the weight of the unit?

-

The Bently Nevada 3500/05-01-02-02-00-01 weighs 4.5 kg.

10. How does this product improve plant reliability?

-

By continuously monitoring critical machinery, it helps detect potential failures early, allowing for timely repairs and minimizing unplanned downtime.

Bently Nevada 3500/05-01-02-02-00-01 3500/05 System Rack

Manufacturer:Bently Nevada

Product Number:3500/05-01-02-02-00-01

Product Type:3500/05 System Rack

Origin:USA

Rack Size:19-inch (14 module slots)

Weight :4.5 kg

Views:30

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/05-01-02-02-00-01 is a component of the Bently Nevada 3500 Machinery Protection System, which is designed for monitoring and protecting industrial machinery. This system is known for its robust performance and is used in various industries to ensure the integrity of critical equipment. The product focuses on vibration monitoring, condition-based maintenance, and advanced diagnostic features to safeguard equipment from potential failures.

The 3500/05-01-02-02-00-01 is a specialized rack for housing Bently Nevada’s machinery protection modules, facilitating the integration of multiple monitoring sensors and devices into a single, centralized unit.

Product Parameters

| Parameter | Details |

|---|---|

| Model | 3500/05-01-02-02-00-01 |

| Rack Size | 19-inch (14 module slots) |

| Weight | 4.5 kg |

| Voltage Input | 85–264V AC |

| Operating Temp | -20°C to 60°C (-4°F to 140°F) |

| Humidity | 5% to 95% RH (non-condensing) |

| Power Consumption | 10W max |

| Mounting | Rack-mounted |

| Certification | CE, UL |

Applications

The Bently Nevada 3500/05-01-02-02-00-01 is used in industrial applications that require continuous monitoring of rotating machinery. Its primary uses include:

Vibration Monitoring – Detects excessive vibration in pumps, motors, turbines, and compressors.

Condition Monitoring – Tracks changes in operating conditions over time for predictive maintenance.

Protective Relaying – Provides automated system shutdowns based on preset alarm thresholds to prevent damage.

Preventive Maintenance – Assists maintenance teams by alerting them to potential mechanical failures before they occur.

Integrated Monitoring Systems – Works with other Bently Nevada products to provide a comprehensive machinery protection solution.

Advantages

Reliability: Known for exceptional durability in harsh industrial environments, the Bently Nevada 3500/05-01-02-02-00-01 is designed to withstand extreme conditions.

Easy Integration: Seamlessly integrates with other components in the Bently Nevada 3500 series, making system expansion straightforward.

Scalable Monitoring: Provides scalable solutions, ideal for both small and large industrial setups.

Advanced Diagnostics: Offers advanced diagnostic capabilities that can detect early signs of mechanical failure, reducing downtime.

Cost-Effective Maintenance: Helps reduce maintenance costs by enabling predictive maintenance rather than reactive repair work.

FAQs

1. What is the purpose of the Bently Nevada 3500/05-01-02-02-00-01?

-

The Bently Nevada 3500/05-01-02-02-00-01 is used as part of a machinery protection system to monitor the condition of critical industrial equipment and prevent catastrophic failures.

2. Can this module be used for any type of machine?

-

Yes, it is designed to monitor various rotating machinery such as turbines, compressors, and motors across multiple industries.

3. How is the unit installed?

-

The unit is rack-mounted and should be installed within a compatible Bently Nevada 3500 system rack.

4. What voltage does this product operate on?

-

The product operates on an AC voltage input range of 85–264V.

5. What is the operating temperature range of this unit?

-

The unit operates in temperatures ranging from -20°C to 60°C (-4°F to 140°F).

6. What type of maintenance is required for this product?

-

The product requires regular checking of sensor connections, as well as monitoring the diagnostic outputs to ensure optimal system performance.

7. Does the Bently Nevada 3500/05-01-02-02-00-01 have any certifications?

-

Yes, it is CE and UL certified for safety and reliability.

8. Can I integrate this with other Bently Nevada products?

-

Yes, it integrates easily with other modules in the Bently Nevada 3500 series, providing a comprehensive machinery monitoring solution.

9. What is the weight of the unit?

-

The Bently Nevada 3500/05-01-02-02-00-01 weighs 4.5 kg.

10. How does this product improve plant reliability?

-

By continuously monitoring critical machinery, it helps detect potential failures early, allowing for timely repairs and minimizing unplanned downtime.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...