Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

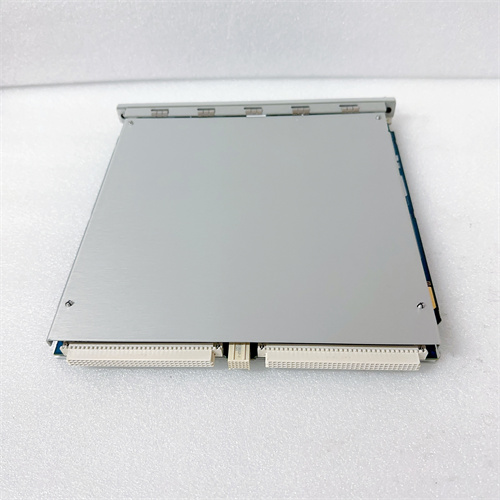

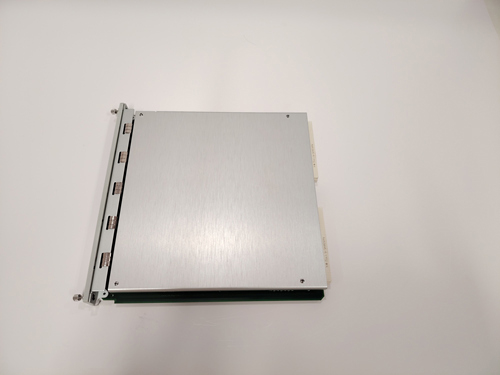

Bently Nevada 330130-085-13-RU 3300 XL Standard Extension Cord

Manufacturer:Bently Nevada

Product Number:330130-085-13-RU

Product Type:3300 XL Standard Extension Cord

Origin:USA

Total Length:8.5 m

Weight :0.289 kg

Views:31

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330130-085-13-RU 3300 XL Standard Extension Cord is designed as part of the 3300 XL series, which is widely used in machinery monitoring and protection systems. This extension cable plays a critical role in connecting proximity probes to monitoring systems, ensuring accurate transmission of vibration and position signals in demanding industrial environments. With its rugged construction, optimized shielding, and high reliability, it supports long-term use in power plants, oil and gas facilities, and other heavy-duty industrial applications.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330130-085-13-RU |

| Series | 3300 XL Standard Extension Cord |

| Total Length | 8.5 m |

| Weight | 0.289 kg |

| Connector Type | Standard 3300 XL |

| Shielding | Full-length shielding |

| Operating Temperature | -35 °C to +125 °C |

| Insulation Material | High-durability polymer |

| Typical Application | Proximity probe extension |

| Compatibility | 3300 XL Proximity Transducer Systems |

Product Applications

-

Vibration and position monitoring systems for rotating machinery

-

Power generation plants for turbine and generator monitoring

-

Oil & gas refineries and petrochemical plants for compressor and pump monitoring

-

Pulp and paper mills for mechanical drive monitoring

-

Steel and heavy industries requiring continuous machinery protection

-

Any critical application where precise signal transmission from probes to monitors is required

Product Advantages

High Signal Integrity: Maintains accurate transmission of vibration and displacement data without loss.

Durability: Engineered for harsh industrial environments with wide temperature resistance.

Seamless Integration: Fully compatible with the Bently Nevada 3300 XL Proximity Transducer System.

Reliable Shielding: Reduces electrical noise interference for consistent measurement accuracy.

Ease of Installation: Standard connectors ensure quick replacement and connection.

Proven Brand Quality: Backed by Bently Nevada’s long-standing expertise in machinery protection and condition monitoring.

FAQ

Q1: What type of transducer system is this extension cord compatible with?

A1: It is compatible with the Bently Nevada 3300 XL Proximity Transducer System.

Q2: Does the extension cord require calibration after installation?

A2: No, calibration is performed at the probe and monitor level; the extension cord itself does not require calibration.

Q3: How does the shielding of this cable improve performance?

A3: Full-length shielding reduces electrical interference and maintains measurement signal integrity.

Q4: Can this extension cord be used in high-temperature industrial areas?

A4: Yes, it is designed to operate within a temperature range of -35 °C to +125 °C.

Q5: Is the extension cord interchangeable with other 3300 XL cable lengths?

A5: Yes, it can be interchanged as long as the total system length matches the transducer system requirements.

Q6: Does the extension cord affect phase accuracy in vibration measurements?

A6: No, the cord is engineered to preserve both amplitude and phase accuracy.

Q7: How does this cord handle electrical noise from motors or high-voltage lines?

A7: The robust shielding design significantly minimizes electrical noise pickup.

Q8: Can the extension cord be used in hazardous area installations?

A8: Yes, when paired with appropriate intrinsically safe barriers and certified monitoring equipment.

Q9: What is the recommended installation practice for maintaining signal reliability?

A9: It is recommended to avoid routing the cord parallel to high-voltage power cables and to ensure proper grounding.

Q10: Does the cord support both static and dynamic measurements?

A10: Yes, it transmits both vibration (dynamic) and position (static) signals accurately.

Bently Nevada 330130-085-13-RU 3300 XL Standard Extension Cord

Manufacturer:Bently Nevada

Product Number:330130-085-13-RU

Product Type:3300 XL Standard Extension Cord

Origin:USA

Total Length:8.5 m

Weight :0.289 kg

Views:31

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330130-085-13-RU 3300 XL Standard Extension Cord is designed as part of the 3300 XL series, which is widely used in machinery monitoring and protection systems. This extension cable plays a critical role in connecting proximity probes to monitoring systems, ensuring accurate transmission of vibration and position signals in demanding industrial environments. With its rugged construction, optimized shielding, and high reliability, it supports long-term use in power plants, oil and gas facilities, and other heavy-duty industrial applications.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330130-085-13-RU |

| Series | 3300 XL Standard Extension Cord |

| Total Length | 8.5 m |

| Weight | 0.289 kg |

| Connector Type | Standard 3300 XL |

| Shielding | Full-length shielding |

| Operating Temperature | -35 °C to +125 °C |

| Insulation Material | High-durability polymer |

| Typical Application | Proximity probe extension |

| Compatibility | 3300 XL Proximity Transducer Systems |

Product Applications

-

Vibration and position monitoring systems for rotating machinery

-

Power generation plants for turbine and generator monitoring

-

Oil & gas refineries and petrochemical plants for compressor and pump monitoring

-

Pulp and paper mills for mechanical drive monitoring

-

Steel and heavy industries requiring continuous machinery protection

-

Any critical application where precise signal transmission from probes to monitors is required

Product Advantages

High Signal Integrity: Maintains accurate transmission of vibration and displacement data without loss.

Durability: Engineered for harsh industrial environments with wide temperature resistance.

Seamless Integration: Fully compatible with the Bently Nevada 3300 XL Proximity Transducer System.

Reliable Shielding: Reduces electrical noise interference for consistent measurement accuracy.

Ease of Installation: Standard connectors ensure quick replacement and connection.

Proven Brand Quality: Backed by Bently Nevada’s long-standing expertise in machinery protection and condition monitoring.

FAQ

Q1: What type of transducer system is this extension cord compatible with?

A1: It is compatible with the Bently Nevada 3300 XL Proximity Transducer System.

Q2: Does the extension cord require calibration after installation?

A2: No, calibration is performed at the probe and monitor level; the extension cord itself does not require calibration.

Q3: How does the shielding of this cable improve performance?

A3: Full-length shielding reduces electrical interference and maintains measurement signal integrity.

Q4: Can this extension cord be used in high-temperature industrial areas?

A4: Yes, it is designed to operate within a temperature range of -35 °C to +125 °C.

Q5: Is the extension cord interchangeable with other 3300 XL cable lengths?

A5: Yes, it can be interchanged as long as the total system length matches the transducer system requirements.

Q6: Does the extension cord affect phase accuracy in vibration measurements?

A6: No, the cord is engineered to preserve both amplitude and phase accuracy.

Q7: How does this cord handle electrical noise from motors or high-voltage lines?

A7: The robust shielding design significantly minimizes electrical noise pickup.

Q8: Can the extension cord be used in hazardous area installations?

A8: Yes, when paired with appropriate intrinsically safe barriers and certified monitoring equipment.

Q9: What is the recommended installation practice for maintaining signal reliability?

A9: It is recommended to avoid routing the cord parallel to high-voltage power cables and to ensure proper grounding.

Q10: Does the cord support both static and dynamic measurements?

A10: Yes, it transmits both vibration (dynamic) and position (static) signals accurately.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...