Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

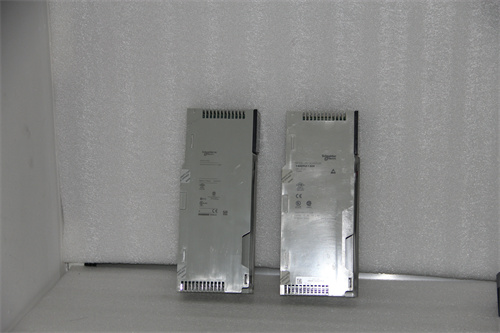

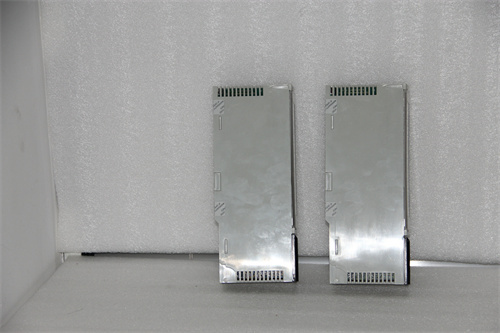

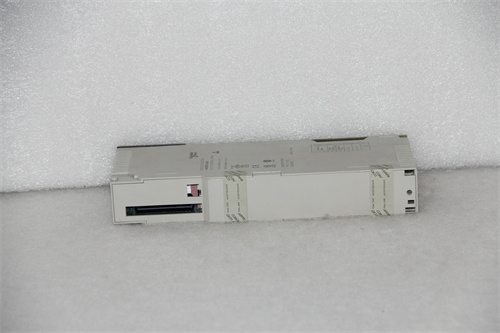

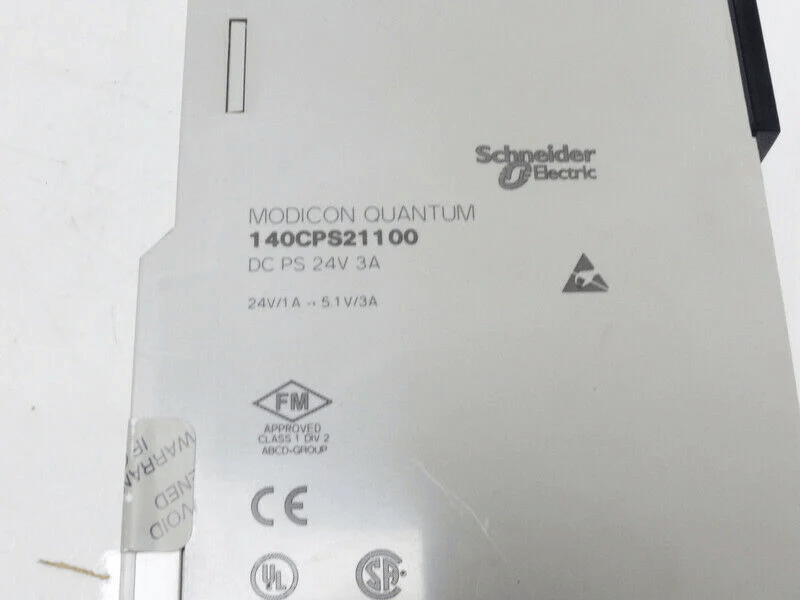

Schneider 140DII33000C Intrinsically Safe Current Input Module

Manufacturer:Schneider

Product Number:140DII33000C

Product Type:Intrinsically Safe Current Input Module

Origin:France

Dimensions:103.9 × 40.3 × 250 mm

Weight:0.3 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 140DII33000C is an Intrinsically Safe (IS) Analog Current Input Module designed for the Modicon Quantum automation platform. This module is specifically built to interface with analog sensors and transmitters located in hazardous areas, such as ATEX Zone 1 or Zone 2 environments, where explosive gases or dust may be present.

With 8 isolated input channels, each capable of accepting standard 4–20 mA signals, the module ensures both high signal fidelity and safe operation in volatile conditions. The intrinsic safety design prevents the release of energy that could ignite hazardous materials, making it an essential component in control systems used in oil & gas, chemical, and pharmaceutical industries.

Its integration within the Quantum platform allows for centralized diagnostics, seamless I/O mapping, and secure performance across large-scale distributed systems.

Product Specifications

| Parameter | Description |

|---|---|

| Product Name | Intrinsically Safe Analog Input Module |

| Part Number | 140DII33000C |

| Manufacturer | Schneider Electric |

| Platform | Modicon Quantum |

| Number of Channels | 8 isolated channels |

| Signal Type | Analog current (4–20 mA) |

| Channel Isolation | Channel-to-channel and channel-to-bus isolation |

| Input Resistance | Approx. 250 ohms |

| Intrinsic Safety Rating | IECEx / ATEX Zone 1 & Zone 2 approved |

| Response Time | < 2 ms per channel |

| Resolution | 15-bit |

| Accuracy | ±0.1% full scale at 25°C |

| Operating Voltage | Supplied via Quantum backplane (5V) |

| Power Consumption | Approx. 2.5 W |

| LED Indicators | Channel status, module diagnostics |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions | 103.9 × 40.3 × 250 mm |

| Weight | 0.3 kg |

| Certifications | ATEX, IECEx, UL, CSA, CE, RoHS compliant |

Applications

The Schneider 140DII33000C is ideal for environments that require accurate measurement of analog current signals under intrinsically safe (IS) conditions. Typical use cases include:

Oil & Gas Facilities: Interface with 4–20 mA transmitters in hazardous zones for pressure, flow, and temperature monitoring.

Chemical Plants: Safe analog signal acquisition from IS sensors located in explosive gas areas.

Pharmaceutical Manufacturing: Integration with IS-qualified sensors in cleanroom or volatile compound areas.

Mining Operations: Remote measurement of conditions in underground, hazardous zones.

Refining Plants: Analog signal monitoring in flammable environments.

Waste Treatment Plants: Safe analog input gathering from explosive-prone sewage gas environments.

Product Advantages

Intrinsic Safety Compliance: Certified for hazardous zones, removing the need for external barriers or isolators.

High Accuracy & Resolution: Ensures detailed monitoring and process control with 15-bit resolution.

Channel Isolation: Prevents cross-channel interference and enhances signal integrity.

Fast Sampling Time: Real-time monitoring enabled by sub-2 ms channel response.

Simplified Installation: Designed for easy integration into Quantum racks with automatic configuration support.

Robust Diagnostics: LED indicators allow for quick fault detection and maintenance.

Compact Footprint: Single-slot width optimizes rack space in control panels.

Frequently Asked Questions (FAQ)

1. What makes this module intrinsically safe?

It limits electrical and thermal energy to prevent ignition in hazardous areas, complying with ATEX and IECEx standards.

2. How many input signals can this module accept?

The 140DII33000C accepts 8 independent 4–20 mA current signals across isolated channels.

3. Can this module be used outside of hazardous zones?

Yes, it functions in both safe and hazardous environments, offering intrinsic safety as an added protection layer.

4. Does the module support diagnostic feedback?

Yes, each channel has LED indicators for status, and the system can log faults for maintenance.

5. What type of field devices can be connected?

Any 4–20 mA analog transmitter certified for IS zones—such as pressure, level, or flow transmitters.

6. Is external signal conditioning required?

No, the module directly interfaces with IS field devices without the need for external isolators or barriers.

7. Is the wiring for this module different from standard AI modules?

Wiring must comply with IS installation practices using approved cable types and segregation from non-IS circuits.

8. What tools are used to configure this module?

It is configured via Schneider’s Unity Pro or EcoStruxure Control Expert software.

9. Can I mix this module with standard I/O on the same rack?

Yes, as long as proper separation and installation guidelines for IS and non-IS circuits are followed.

10. How do I ensure compliance with hazardous location regulations?

Use IS-certified field devices, follow ATEX/IECEx wiring practices, and consult your site safety engineer.

Schneider 140DII33000C Intrinsically Safe Current Input Module

Manufacturer:Schneider

Product Number:140DII33000C

Product Type:Intrinsically Safe Current Input Module

Origin:France

Dimensions:103.9 × 40.3 × 250 mm

Weight:0.3 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 140DII33000C is an Intrinsically Safe (IS) Analog Current Input Module designed for the Modicon Quantum automation platform. This module is specifically built to interface with analog sensors and transmitters located in hazardous areas, such as ATEX Zone 1 or Zone 2 environments, where explosive gases or dust may be present.

With 8 isolated input channels, each capable of accepting standard 4–20 mA signals, the module ensures both high signal fidelity and safe operation in volatile conditions. The intrinsic safety design prevents the release of energy that could ignite hazardous materials, making it an essential component in control systems used in oil & gas, chemical, and pharmaceutical industries.

Its integration within the Quantum platform allows for centralized diagnostics, seamless I/O mapping, and secure performance across large-scale distributed systems.

Product Specifications

| Parameter | Description |

|---|---|

| Product Name | Intrinsically Safe Analog Input Module |

| Part Number | 140DII33000C |

| Manufacturer | Schneider Electric |

| Platform | Modicon Quantum |

| Number of Channels | 8 isolated channels |

| Signal Type | Analog current (4–20 mA) |

| Channel Isolation | Channel-to-channel and channel-to-bus isolation |

| Input Resistance | Approx. 250 ohms |

| Intrinsic Safety Rating | IECEx / ATEX Zone 1 & Zone 2 approved |

| Response Time | < 2 ms per channel |

| Resolution | 15-bit |

| Accuracy | ±0.1% full scale at 25°C |

| Operating Voltage | Supplied via Quantum backplane (5V) |

| Power Consumption | Approx. 2.5 W |

| LED Indicators | Channel status, module diagnostics |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions | 103.9 × 40.3 × 250 mm |

| Weight | 0.3 kg |

| Certifications | ATEX, IECEx, UL, CSA, CE, RoHS compliant |

Applications

The Schneider 140DII33000C is ideal for environments that require accurate measurement of analog current signals under intrinsically safe (IS) conditions. Typical use cases include:

Oil & Gas Facilities: Interface with 4–20 mA transmitters in hazardous zones for pressure, flow, and temperature monitoring.

Chemical Plants: Safe analog signal acquisition from IS sensors located in explosive gas areas.

Pharmaceutical Manufacturing: Integration with IS-qualified sensors in cleanroom or volatile compound areas.

Mining Operations: Remote measurement of conditions in underground, hazardous zones.

Refining Plants: Analog signal monitoring in flammable environments.

Waste Treatment Plants: Safe analog input gathering from explosive-prone sewage gas environments.

Product Advantages

Intrinsic Safety Compliance: Certified for hazardous zones, removing the need for external barriers or isolators.

High Accuracy & Resolution: Ensures detailed monitoring and process control with 15-bit resolution.

Channel Isolation: Prevents cross-channel interference and enhances signal integrity.

Fast Sampling Time: Real-time monitoring enabled by sub-2 ms channel response.

Simplified Installation: Designed for easy integration into Quantum racks with automatic configuration support.

Robust Diagnostics: LED indicators allow for quick fault detection and maintenance.

Compact Footprint: Single-slot width optimizes rack space in control panels.

Frequently Asked Questions (FAQ)

1. What makes this module intrinsically safe?

It limits electrical and thermal energy to prevent ignition in hazardous areas, complying with ATEX and IECEx standards.

2. How many input signals can this module accept?

The 140DII33000C accepts 8 independent 4–20 mA current signals across isolated channels.

3. Can this module be used outside of hazardous zones?

Yes, it functions in both safe and hazardous environments, offering intrinsic safety as an added protection layer.

4. Does the module support diagnostic feedback?

Yes, each channel has LED indicators for status, and the system can log faults for maintenance.

5. What type of field devices can be connected?

Any 4–20 mA analog transmitter certified for IS zones—such as pressure, level, or flow transmitters.

6. Is external signal conditioning required?

No, the module directly interfaces with IS field devices without the need for external isolators or barriers.

7. Is the wiring for this module different from standard AI modules?

Wiring must comply with IS installation practices using approved cable types and segregation from non-IS circuits.

8. What tools are used to configure this module?

It is configured via Schneider’s Unity Pro or EcoStruxure Control Expert software.

9. Can I mix this module with standard I/O on the same rack?

Yes, as long as proper separation and installation guidelines for IS and non-IS circuits are followed.

10. How do I ensure compliance with hazardous location regulations?

Use IS-certified field devices, follow ATEX/IECEx wiring practices, and consult your site safety engineer.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...