Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

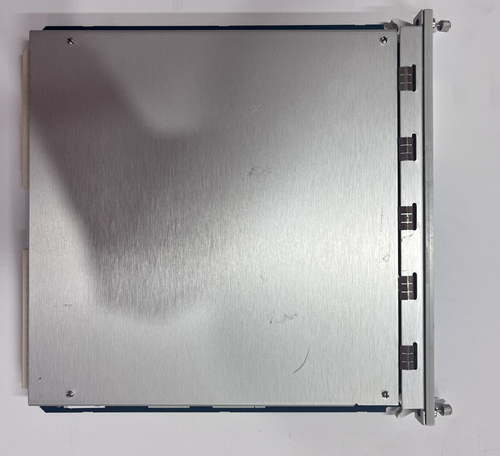

Bently Nevada 330780-51-00 3300 XL 11 mm Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330780-51-00

Product Type:3300 XL 11 mm Proximitor Sensor

Origin:USA

Total Length:5.0 meters

Weight:0.255 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The 330780-51-00 is part of the Bently Nevada 3300 XL 11 mm Proximity Transducer System, specifically designed for non-contact measurement of shaft vibration and position. It delivers precise measurements with a scale factor of 3.94 V/mm (100 mV/mil) and supports applications requiring a longer linear range than the standard 8 mm probes.

Applications

-

Axial (thrust) position monitoring

-

Differential expansion in steam turbines

-

Rod drop/rod position in reciprocating compressors

-

Tachometer and zero-speed detection

-

Keyphasor (phase reference) signals

Advantages

-

Extended linear range up to 4.0 mm

-

Highly robust ClickLoc and CableLoc connectors

-

CE compliant with improved RFI/EMI immunity

-

Flexible DIN or panel mounting options

Field-replaceable components and easy installation

-

Compatible with FluidLoc cable to resist fluid ingress

Technical Specifications

| Parameter | Value |

|---|---|

| System Type | 3300 XL 11 mm Proximitor Sensor |

| Part Number | 330780-51-00 |

| System Length | 5.0 meters |

| Output Scale | 3.94 V/mm (100 mV/mil) |

| Linear Range | 0.5 mm to 4.5 mm |

| Extended DSL Range | 0.5 mm to 5.0 mm |

| Frequency Response | 0 to 8 kHz |

| Power Supply | -17.5 Vdc to -26 Vdc |

| Output Resistance | 50 Ω |

| Operating Temperature (Sensor) | -52°C to +100°C |

| Operating Temperature (Probe) | -52°C to +177°C |

| Humidity | 100% condensing (non-submersible) |

| Mounting | DIN rail (standard for -51 variant) |

| Compliance | SIL 2/SIL 3, ATEX, IECEx, FCC, RoHS |

| Total Length | 5.0 meters |

| Weight | 0.255 kg |

FAQ

Q1: What is the primary use of the 330780-51-00 sensor?

A1: It is used for measuring vibration and shaft position on rotating machinery like turbines and compressors.

Q2: What is the advantage of using an 11 mm probe over an 8 mm one?

A2: The 11 mm probe offers a longer linear measurement range, suitable for large shaft diameters and more complex measurements.

Q3: Is the 330780-51-00 sensor compatible with older 7200-series systems?

A3: No. Upgrading requires replacing all components with 3300 XL series parts and updating the monitoring system.

Q4: Can it be mounted in any orientation?

A4: Yes. It supports both DIN rail and panel mounting options.

Q5: What kind of output does the sensor provide?

A5: It provides a voltage output of 3.94 V/mm (100 mV/mil) for displacement measurements.

Q6: Is it suitable for hazardous environments?

A6: Yes, it is certified for use in hazardous areas with multiple global approvals.

Q7: What precautions should be taken during handling?

A7: Although ESD protection is built-in, standard precautions against static discharge are recommended.

Q8: What is the recommended probe gap setting?

A8: The ideal probe gap is 2.5 mm (100 mils).

Q9: What is the maximum operating frequency?

A9: It supports up to 8 kHz frequency for accurate vibration measurements.

Q10: How much does the system weigh?

A10: The total system weight is approximately 0.255 kg.

Bently Nevada 330780-51-00 3300 XL 11 mm Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330780-51-00

Product Type:3300 XL 11 mm Proximitor Sensor

Origin:USA

Total Length:5.0 meters

Weight:0.255 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The 330780-51-00 is part of the Bently Nevada 3300 XL 11 mm Proximity Transducer System, specifically designed for non-contact measurement of shaft vibration and position. It delivers precise measurements with a scale factor of 3.94 V/mm (100 mV/mil) and supports applications requiring a longer linear range than the standard 8 mm probes.

Applications

-

Axial (thrust) position monitoring

-

Differential expansion in steam turbines

-

Rod drop/rod position in reciprocating compressors

-

Tachometer and zero-speed detection

-

Keyphasor (phase reference) signals

Advantages

-

Extended linear range up to 4.0 mm

-

Highly robust ClickLoc and CableLoc connectors

-

CE compliant with improved RFI/EMI immunity

-

Flexible DIN or panel mounting options

Field-replaceable components and easy installation

-

Compatible with FluidLoc cable to resist fluid ingress

Technical Specifications

| Parameter | Value |

|---|---|

| System Type | 3300 XL 11 mm Proximitor Sensor |

| Part Number | 330780-51-00 |

| System Length | 5.0 meters |

| Output Scale | 3.94 V/mm (100 mV/mil) |

| Linear Range | 0.5 mm to 4.5 mm |

| Extended DSL Range | 0.5 mm to 5.0 mm |

| Frequency Response | 0 to 8 kHz |

| Power Supply | -17.5 Vdc to -26 Vdc |

| Output Resistance | 50 Ω |

| Operating Temperature (Sensor) | -52°C to +100°C |

| Operating Temperature (Probe) | -52°C to +177°C |

| Humidity | 100% condensing (non-submersible) |

| Mounting | DIN rail (standard for -51 variant) |

| Compliance | SIL 2/SIL 3, ATEX, IECEx, FCC, RoHS |

| Total Length | 5.0 meters |

| Weight | 0.255 kg |

FAQ

Q1: What is the primary use of the 330780-51-00 sensor?

A1: It is used for measuring vibration and shaft position on rotating machinery like turbines and compressors.

Q2: What is the advantage of using an 11 mm probe over an 8 mm one?

A2: The 11 mm probe offers a longer linear measurement range, suitable for large shaft diameters and more complex measurements.

Q3: Is the 330780-51-00 sensor compatible with older 7200-series systems?

A3: No. Upgrading requires replacing all components with 3300 XL series parts and updating the monitoring system.

Q4: Can it be mounted in any orientation?

A4: Yes. It supports both DIN rail and panel mounting options.

Q5: What kind of output does the sensor provide?

A5: It provides a voltage output of 3.94 V/mm (100 mV/mil) for displacement measurements.

Q6: Is it suitable for hazardous environments?

A6: Yes, it is certified for use in hazardous areas with multiple global approvals.

Q7: What precautions should be taken during handling?

A7: Although ESD protection is built-in, standard precautions against static discharge are recommended.

Q8: What is the recommended probe gap setting?

A8: The ideal probe gap is 2.5 mm (100 mils).

Q9: What is the maximum operating frequency?

A9: It supports up to 8 kHz frequency for accurate vibration measurements.

Q10: How much does the system weigh?

A10: The total system weight is approximately 0.255 kg.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...