Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

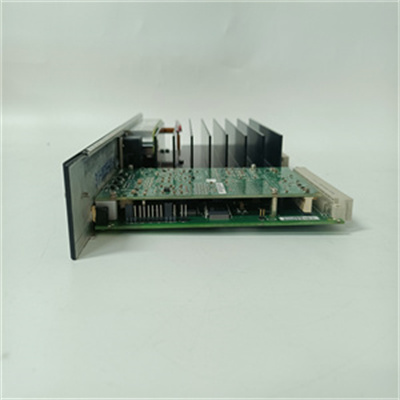

General Electric IS210BPPCH1AD I/O Pack Processor Card

Manufacturer:GE

Product Number:IS210BPPCH1AD

Product Type: I/O Pack Processor Card

Origin:USA

Dimensions:200 × 100 × 25 mm

Weight:0.58 kg

Views:3

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS210BPPCH1AD I/O Pack Processor Card is a high-performance processing unit designed for use in the GE Mark VIe control platform. It acts as the primary interface between field I/O signals and the central control system, ensuring real-time data acquisition, conditioning, and communication.

This module provides the computational capability required to manage a wide range of analog and digital signals, while its robust construction ensures reliability in demanding industrial applications. The IS210BPPCH1AD is widely adopted in turbine control, power generation, petrochemical industries, and large-scale automation systems where stability and precision are essential.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IS210BPPCH1AD |

| Product Type | I/O Pack Processor Card |

| System Compatibility | GE Mark VIe Control Systems |

| Processor | Embedded high-speed microprocessor |

| Supported I/O | Mixed analog and digital channels |

| Signal Conditioning | Integrated isolation and noise filtering |

| Communication Interface | Ethernet-based network connectivity |

| Data Update Rate | < 10 ms typical |

| Redundancy | Supports redundant system configurations |

| Diagnostic Features | Self-checking and error reporting |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, CSA |

| Dimensions | 200 × 100 × 25 mm |

| Weight | 0.58 kg |

| Mounting | Plug-in module, rack/backplane installation |

Product Applications

The GE IS210BPPCH1AD I/O Pack Processor Card is designed for high-performance industrial applications. Some of the common applications include:

Gas and Steam Turbine Control – Provides high-speed data handling for turbine feedback and actuator signals.

Power Plant Automation – Used for signal acquisition from sensors monitoring vibration, pressure, and temperature.

Oil and Gas Industry – Interfaces with safety and control systems in petrochemical environments.

Industrial Process Control – Ensures reliable input/output management in distributed control systems.

Critical Safety Systems – Maintains integrity of control signals in safety-related operations.

Product Advantages

High-Speed Processing – Enables precise real-time control of complex industrial processes.

Reliable Communication – Ethernet connectivity ensures fast and deterministic data transfer.

Enhanced Signal Integrity – Built-in filtering and isolation reduce noise effects in harsh environments.

Scalable and Flexible – Supports expansion for additional I/O packs and future system upgrades.

Robust Design – Engineered for continuous operation in industrial conditions with high reliability.

Comprehensive Diagnostics – Provides advanced fault detection and reporting to minimize downtime.

FAQ

What communication protocol does the IS210BPPCH1AD use with the Mark VIe system?

It uses Ethernet-based communication, which allows for high-speed and deterministic data transfer.

How does the IS210BPPCH1AD maintain signal reliability in noisy industrial environments?

The module features advanced isolation and filtering circuits that ensure stable analog and digital signal processing.

Can the IS210BPPCH1AD handle both analog and digital signals simultaneously?

Yes, it is specifically designed to support multiple analog and digital I/O channels in parallel.

What redundancy features does the IS210BPPCH1AD provide?

It supports redundant system configurations, enabling automatic failover in critical applications.

What is the typical data update rate supported by the IS210BPPCH1AD?

The module achieves a data update rate of less than 10 ms, suitable for real-time turbine and process control.

How is the IS210BPPCH1AD integrated into the Mark VIe system?

It installs as a plug-in module on the system backplane, ensuring secure mechanical and electrical integration.

What diagnostic functions are available in the IS210BPPCH1AD?

It includes built-in self-checks, error detection, and reporting features that communicate directly to the controller.

Does the IS210BPPCH1AD support remote monitoring of its status?

Yes, it provides diagnostic and operational status information accessible through the control system.

How does the IS210BPPCH1AD ensure accurate output under heavy loads?

The module uses buffered and regulated output circuits to maintain stability even in demanding load conditions.

Can the IS210BPPCH1AD be used in critical safety applications?

Yes, its high reliability and diagnostic functions make it suitable for safety-related control environments.

General Electric IS210BPPCH1AD I/O Pack Processor Card

Manufacturer:GE

Product Number:IS210BPPCH1AD

Product Type: I/O Pack Processor Card

Origin:USA

Dimensions:200 × 100 × 25 mm

Weight:0.58 kg

Views:3

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS210BPPCH1AD I/O Pack Processor Card is a high-performance processing unit designed for use in the GE Mark VIe control platform. It acts as the primary interface between field I/O signals and the central control system, ensuring real-time data acquisition, conditioning, and communication.

This module provides the computational capability required to manage a wide range of analog and digital signals, while its robust construction ensures reliability in demanding industrial applications. The IS210BPPCH1AD is widely adopted in turbine control, power generation, petrochemical industries, and large-scale automation systems where stability and precision are essential.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IS210BPPCH1AD |

| Product Type | I/O Pack Processor Card |

| System Compatibility | GE Mark VIe Control Systems |

| Processor | Embedded high-speed microprocessor |

| Supported I/O | Mixed analog and digital channels |

| Signal Conditioning | Integrated isolation and noise filtering |

| Communication Interface | Ethernet-based network connectivity |

| Data Update Rate | < 10 ms typical |

| Redundancy | Supports redundant system configurations |

| Diagnostic Features | Self-checking and error reporting |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, CSA |

| Dimensions | 200 × 100 × 25 mm |

| Weight | 0.58 kg |

| Mounting | Plug-in module, rack/backplane installation |

Product Applications

The GE IS210BPPCH1AD I/O Pack Processor Card is designed for high-performance industrial applications. Some of the common applications include:

Gas and Steam Turbine Control – Provides high-speed data handling for turbine feedback and actuator signals.

Power Plant Automation – Used for signal acquisition from sensors monitoring vibration, pressure, and temperature.

Oil and Gas Industry – Interfaces with safety and control systems in petrochemical environments.

Industrial Process Control – Ensures reliable input/output management in distributed control systems.

Critical Safety Systems – Maintains integrity of control signals in safety-related operations.

Product Advantages

High-Speed Processing – Enables precise real-time control of complex industrial processes.

Reliable Communication – Ethernet connectivity ensures fast and deterministic data transfer.

Enhanced Signal Integrity – Built-in filtering and isolation reduce noise effects in harsh environments.

Scalable and Flexible – Supports expansion for additional I/O packs and future system upgrades.

Robust Design – Engineered for continuous operation in industrial conditions with high reliability.

Comprehensive Diagnostics – Provides advanced fault detection and reporting to minimize downtime.

FAQ

What communication protocol does the IS210BPPCH1AD use with the Mark VIe system?

It uses Ethernet-based communication, which allows for high-speed and deterministic data transfer.

How does the IS210BPPCH1AD maintain signal reliability in noisy industrial environments?

The module features advanced isolation and filtering circuits that ensure stable analog and digital signal processing.

Can the IS210BPPCH1AD handle both analog and digital signals simultaneously?

Yes, it is specifically designed to support multiple analog and digital I/O channels in parallel.

What redundancy features does the IS210BPPCH1AD provide?

It supports redundant system configurations, enabling automatic failover in critical applications.

What is the typical data update rate supported by the IS210BPPCH1AD?

The module achieves a data update rate of less than 10 ms, suitable for real-time turbine and process control.

How is the IS210BPPCH1AD integrated into the Mark VIe system?

It installs as a plug-in module on the system backplane, ensuring secure mechanical and electrical integration.

What diagnostic functions are available in the IS210BPPCH1AD?

It includes built-in self-checks, error detection, and reporting features that communicate directly to the controller.

Does the IS210BPPCH1AD support remote monitoring of its status?

Yes, it provides diagnostic and operational status information accessible through the control system.

How does the IS210BPPCH1AD ensure accurate output under heavy loads?

The module uses buffered and regulated output circuits to maintain stability even in demanding load conditions.

Can the IS210BPPCH1AD be used in critical safety applications?

Yes, its high reliability and diagnostic functions make it suitable for safety-related control environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...