Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

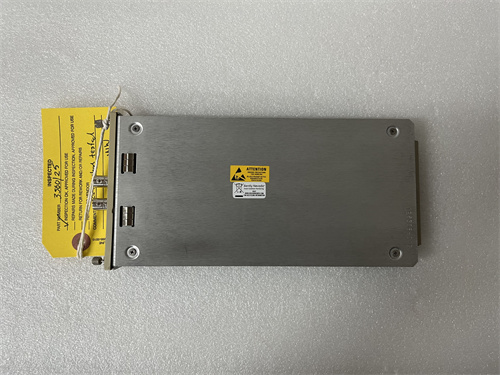

Bently Nevada 330854-080-24-CN 3300 XL 25 mm Extension Cable

Manufacturer:Bently Nevada

Product Number:330854-080-24-CN

Product Type:3300 XL 25 mm Extension Cable

Origin:USA

Cable Length:8 m

Weight:0.36 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330854-080-24-CN is a part of the renowned 3300 XL Series, designed to deliver reliable signal transmission in industrial condition monitoring systems. This specific model is a 25 mm Extension Cable, part of the three-component system used with proximity probes and Proximitor sensors. Engineered by Bently Nevada, a leader in machinery protection and predictive maintenance, the 330854-080-24-CN supports vibration and position measurement in harsh environments like oil & gas, power generation, and rotating machinery sectors.

As a 8 meters extension cable, this component ensures high-integrity signal transmission between the probe and the monitoring device. Its rugged design, coupled with robust EMI/RFI shielding and connector locking mechanisms, makes it ideal for critical applications where uptime is crucial.

Product Specifications

| Parameter | Value |

| Product Name | 330854-080-24-CN |

| Series | Bently Nevada 3300 XL |

| Function | Extension Cable for Proximity Probe System |

| Cable Length | 8 meters |

| Probe Compatibility | 3300 XL Proximity Transducer Systems |

| Connector Type | MIL-C-5015 Standard, Keyphasor-compatible |

| Cable Jacket Material | Polyethylene or PFA (Environmental-resistant) |

| Minimum Bend Radius | 2.5 inches (63.5 mm) |

| Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Electrical Shielding | Double shielding for noise immunity |

| Insulation Resistance | >10⁹ ohms @ 500 VDC |

| Weight | 0.36 kg |

| Compliance | CE, RoHS, CSA, ATEX (depending on system use) |

Product Applications

Rotating Machinery Monitoring: Extensively used with turbines, compressors, motors, and pumps.

Oil & Gas Sector: Ideal for use in upstream, midstream, and downstream equipment health monitoring.

Power Generation: Enables vibration diagnostics for steam and gas turbines.

Refineries & Petrochemical Plants: Monitors balance-of-plant and critical rotating assets.

Marine & Aerospace: Applied in monitoring propulsion and auxiliary systems.

Heavy Industry: Cement, mining, and steel industries use this cable in condition monitoring frameworks.

Product Advantages

High Signal Integrity: Minimizes signal degradation over long distances.

Rugged Construction: Withstands high temperatures and mechanical stress.

EMI/RFI Protection: Dual-shielding prevents electromagnetic interference.

Easy Integration: Compatible with existing 3300 XL and Bently Nevada monitoring systems.

Environmental Resistance: Durable outer jacket material resists oil, chemicals, and moisture.

Long-Term Reliability: Designed for continuous industrial use over extended lifecycles.

Secure Connection: Locking connectors prevent signal loss or accidental disconnection.

Simplified Maintenance: Field-replaceable and easy to install without special tools.

Frequently Asked Questions (FAQ)

-

Can the 330854-080-24-CN extension cable be used in high-vibration environments?

Yes, it is designed specifically for use in high-vibration zones such as turbine housings and compressor bodies. Its rugged construction ensures minimal signal degradation even under continuous mechanical stress.

-

What is the maximum total system length when using this cable with a 3300 XL probe and Proximitor?

The total system length must be 15 meters (49.2 feet) or 20 meters (65.6 feet), depending on the system configuration. This includes the probe cable, extension cable (like 330854-080-24-CN), and the cable from the extension to the Proximitor.

-

Does the cable require shielding for EMI protection?

No additional shielding is required. The 330854 series comes with double-shielded construction, which effectively protects signal integrity in environments with high electromagnetic interference.

-

How do I determine if 80 feet is the correct cable length for my setup?

You must calculate the total system length between the probe tip and the Proximitor input. If 80 feet is too long, signal fidelity and phase response can be compromised. Always match the cable length to the factory-calibrated configuration.

-

Is field termination or customization of this cable recommended?

No. Field termination is not recommended because it can affect calibration and signal accuracy. These cables are pre-terminated and calibrated at the factory to ensure proper system response.

-

What type of connectors does this cable use?

It uses MIL-C-5015-style connectors, which are designed for secure, vibration-resistant engagement. These are industry-standard connectors used in most Bently Nevada systems.

-

Can this cable be used in proximity systems for axial as well as radial vibration monitoring?

Yes, it supports both axial and radial position and vibration measurements, as long as it’s used with the appropriate probes and drivers from the 3300 XL family.

-

Is the 330854-080-24-CN interchangeable with the 330130 series cables?

Functionally, both serve similar roles, but the 330854 is part of the newer 3300 XL system and provides improved durability, EMI shielding, and thermal tolerance. Mixing cables from different series is not recommended unless specified by the manufacturer.

-

What is the bend radius, and why is it important?

The minimum bend radius is 2.5 inches (63.5 mm). Exceeding this can stress the cable’s internal shielding and insulation, possibly causing early failure or signal noise.

-

How often should this cable be inspected or replaced in critical systems?

While the cable is built for long-term use, a visual and continuity inspection is recommended during every scheduled outage or maintenance cycle. If exposed to frequent mechanical movement, inspection frequency should increase.

Bently Nevada 330854-080-24-CN 3300 XL 25 mm Extension Cable

Manufacturer:Bently Nevada

Product Number:330854-080-24-CN

Product Type:3300 XL 25 mm Extension Cable

Origin:USA

Cable Length:8 m

Weight:0.36 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330854-080-24-CN is a part of the renowned 3300 XL Series, designed to deliver reliable signal transmission in industrial condition monitoring systems. This specific model is a 25 mm Extension Cable, part of the three-component system used with proximity probes and Proximitor sensors. Engineered by Bently Nevada, a leader in machinery protection and predictive maintenance, the 330854-080-24-CN supports vibration and position measurement in harsh environments like oil & gas, power generation, and rotating machinery sectors.

As a 8 meters extension cable, this component ensures high-integrity signal transmission between the probe and the monitoring device. Its rugged design, coupled with robust EMI/RFI shielding and connector locking mechanisms, makes it ideal for critical applications where uptime is crucial.

Product Specifications

| Parameter | Value |

| Product Name | 330854-080-24-CN |

| Series | Bently Nevada 3300 XL |

| Function | Extension Cable for Proximity Probe System |

| Cable Length | 8 meters |

| Probe Compatibility | 3300 XL Proximity Transducer Systems |

| Connector Type | MIL-C-5015 Standard, Keyphasor-compatible |

| Cable Jacket Material | Polyethylene or PFA (Environmental-resistant) |

| Minimum Bend Radius | 2.5 inches (63.5 mm) |

| Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Electrical Shielding | Double shielding for noise immunity |

| Insulation Resistance | >10⁹ ohms @ 500 VDC |

| Weight | 0.36 kg |

| Compliance | CE, RoHS, CSA, ATEX (depending on system use) |

Product Applications

Rotating Machinery Monitoring: Extensively used with turbines, compressors, motors, and pumps.

Oil & Gas Sector: Ideal for use in upstream, midstream, and downstream equipment health monitoring.

Power Generation: Enables vibration diagnostics for steam and gas turbines.

Refineries & Petrochemical Plants: Monitors balance-of-plant and critical rotating assets.

Marine & Aerospace: Applied in monitoring propulsion and auxiliary systems.

Heavy Industry: Cement, mining, and steel industries use this cable in condition monitoring frameworks.

Product Advantages

High Signal Integrity: Minimizes signal degradation over long distances.

Rugged Construction: Withstands high temperatures and mechanical stress.

EMI/RFI Protection: Dual-shielding prevents electromagnetic interference.

Easy Integration: Compatible with existing 3300 XL and Bently Nevada monitoring systems.

Environmental Resistance: Durable outer jacket material resists oil, chemicals, and moisture.

Long-Term Reliability: Designed for continuous industrial use over extended lifecycles.

Secure Connection: Locking connectors prevent signal loss or accidental disconnection.

Simplified Maintenance: Field-replaceable and easy to install without special tools.

Frequently Asked Questions (FAQ)

-

Can the 330854-080-24-CN extension cable be used in high-vibration environments?

Yes, it is designed specifically for use in high-vibration zones such as turbine housings and compressor bodies. Its rugged construction ensures minimal signal degradation even under continuous mechanical stress.

-

What is the maximum total system length when using this cable with a 3300 XL probe and Proximitor?

The total system length must be 15 meters (49.2 feet) or 20 meters (65.6 feet), depending on the system configuration. This includes the probe cable, extension cable (like 330854-080-24-CN), and the cable from the extension to the Proximitor.

-

Does the cable require shielding for EMI protection?

No additional shielding is required. The 330854 series comes with double-shielded construction, which effectively protects signal integrity in environments with high electromagnetic interference.

-

How do I determine if 80 feet is the correct cable length for my setup?

You must calculate the total system length between the probe tip and the Proximitor input. If 80 feet is too long, signal fidelity and phase response can be compromised. Always match the cable length to the factory-calibrated configuration.

-

Is field termination or customization of this cable recommended?

No. Field termination is not recommended because it can affect calibration and signal accuracy. These cables are pre-terminated and calibrated at the factory to ensure proper system response.

-

What type of connectors does this cable use?

It uses MIL-C-5015-style connectors, which are designed for secure, vibration-resistant engagement. These are industry-standard connectors used in most Bently Nevada systems.

-

Can this cable be used in proximity systems for axial as well as radial vibration monitoring?

Yes, it supports both axial and radial position and vibration measurements, as long as it’s used with the appropriate probes and drivers from the 3300 XL family.

-

Is the 330854-080-24-CN interchangeable with the 330130 series cables?

Functionally, both serve similar roles, but the 330854 is part of the newer 3300 XL system and provides improved durability, EMI shielding, and thermal tolerance. Mixing cables from different series is not recommended unless specified by the manufacturer.

-

What is the bend radius, and why is it important?

The minimum bend radius is 2.5 inches (63.5 mm). Exceeding this can stress the cable’s internal shielding and insulation, possibly causing early failure or signal noise.

-

How often should this cable be inspected or replaced in critical systems?

While the cable is built for long-term use, a visual and continuity inspection is recommended during every scheduled outage or maintenance cycle. If exposed to frequent mechanical movement, inspection frequency should increase.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...