Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

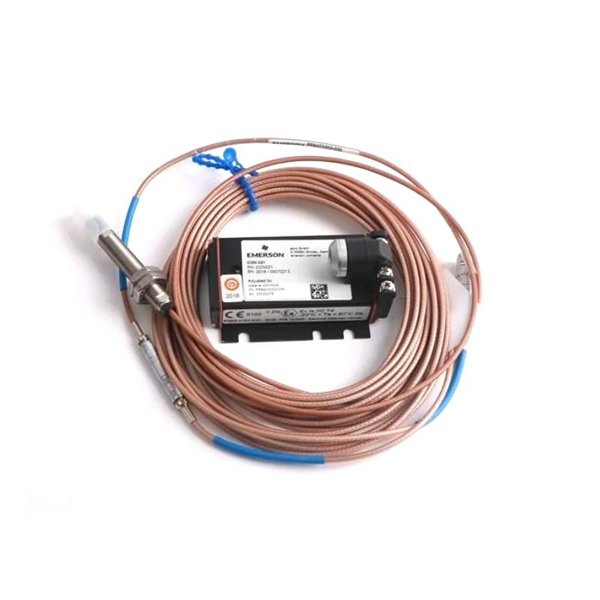

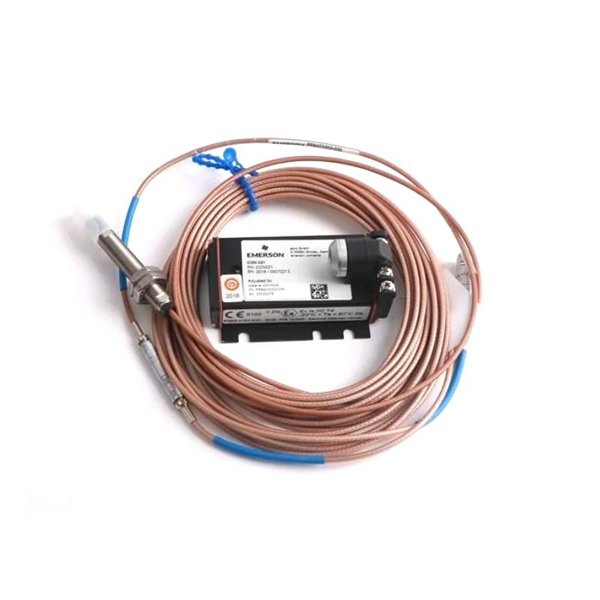

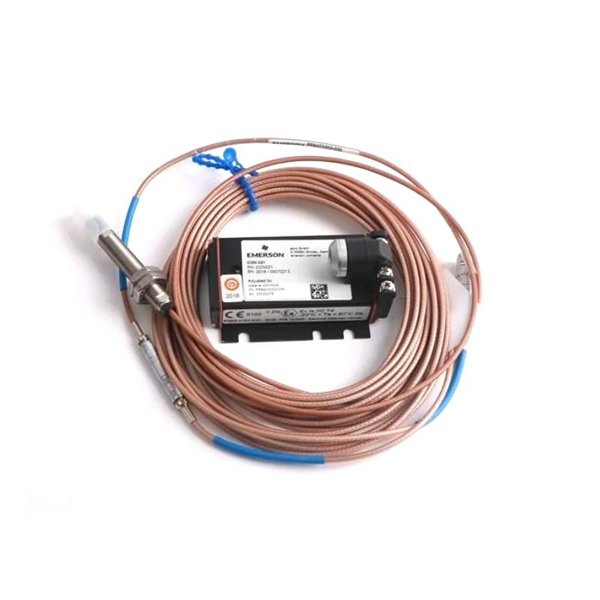

Epro PR6453/230-101 12.5mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6453/230-101

Product Type:12.5mm Eddy Current Sensor

Origin:Germany

Sensor Head Diameter:12.5 mm

Weight:0.8 kg

Views:63

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6453/230-101 is a robust and highly sensitive eddy current displacement sensor designed for precise non-contact measurement of shaft displacement, vibration, and position. With a sensing tip diameter of 12.5 mm, this sensor is optimized for industrial applications requiring accurate monitoring of rotating machinery. Developed by Epro, a renowned manufacturer in the field of industrial condition monitoring, this model is compatible with various signal conditioners such as CON011 or CON021 and integrates seamlessly into comprehensive machine protection and diagnostic systems.

Constructed with a rugged stainless-steel body and engineered to withstand harsh environments, the PR6453/230-101 sensor ensures consistent performance under temperature fluctuations, oil exposure, and high mechanical stress, making it suitable for critical machinery in industries such as power generation, petrochemicals, and manufacturing.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | PR6453/230-101 |

| Sensing Principle | Eddy Current / Non-contact |

| Sensor Head Diameter | 12.5 mm |

| Measuring Range | ±1.0 mm to ±2.0 mm (depending on configuration) |

| Linear Range | 0.25 – 2.0 mm (target material dependent) |

| Sensitivity | Factory-calibrated to application range |

| Material (Housing) | Stainless Steel |

| Operating Temperature | -35°C to +180°C (sensor only) |

| Storage Temperature | -40°C to +200°C |

| Output Signal | Analog voltage (via CON011/CON021) |

| Connection Cable | Integrated coaxial cable |

| Mounting Type | Threaded sleeve (optional accessories available) |

| Protection Class | IP65 or higher (depending on installation) |

| Typical Target Material | Steel (AISI 4140 or equivalent) |

| Weight | 0.8 kg |

Applications

The PR6453/230-101 eddy current sensor is widely used across industries where high-precision shaft position and vibration monitoring are essential for safety, maintenance, and operational efficiency. Key application areas include:

Turbomachinery monitoring: Gas turbines, steam turbines, compressors

Pumps and motors: Monitoring shaft displacement and thermal expansion

Gearboxes and bearings: Vibration and misalignment detection

Condition monitoring systems: Integrated in Epro or third-party CMS platforms

Predictive maintenance: Early detection of wear, imbalance, and failure

OEM machinery integration: Embedded within critical rotating equipment

Advantages

Non-contact measurement: Prevents wear and allows continuous monitoring

High temperature resistance: Operates reliably in extreme environments

Robust construction: Designed for industrial use with stainless steel body

High accuracy and repeatability: Factory-calibrated to ensure consistency

Long service life: Minimal maintenance due to solid-state design

Seamless integration: Compatible with Epro CON011, CON021 signal converters

Compact design: Fits into tight installations and retrofitting scenarios

Vibration and shock resistant: Stable performance even under mechanical stress

Modular system: Easy to upgrade or replace in existing setups

Global support: Backed by Epro’s extensive technical network

FAQ

What is the measuring range of the PR6453/230-101 sensor?

It typically supports a linear range between 0.25 mm to 2.0 mm depending on the material and system setup.

Can this sensor be used at high temperatures?

Yes, the PR6453/230-101 can operate at temperatures up to 180°C, making it suitable for harsh environments.

What type of signal conditioner should I use with this sensor?

It is designed to work with Epro CON011 or CON021 converters.

Is the sensor compatible with non-ferromagnetic targets?

It is primarily calibrated for ferromagnetic materials like steel; accuracy may vary with other materials.

What kind of installation does the sensor require?

It typically mounts using threaded sleeves or brackets and requires proper alignment to the shaft or surface.

How long is the sensor’s standard cable?

Cable length can vary by order; standard versions come with fixed-length coaxial cables, customizable upon request.

Can this sensor detect shaft vibration and displacement simultaneously?

Yes, the sensor detects both parameters through the same analog signal depending on interpretation.

What certifications does this sensor have?

Typically, it complies with CE standards and may support ATEX/IECEx depending on configuration (verify with manufacturer).

Can this sensor be installed in a hazardous area?

Yes, when used with the appropriate certified converter and housing, it can be installed in classified zones.

Is recalibration necessary over time?

Not frequently. However, recalibration is advised during major maintenance intervals or system upgrades.

Epro PR6453/230-101 12.5mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6453/230-101

Product Type:12.5mm Eddy Current Sensor

Origin:Germany

Sensor Head Diameter:12.5 mm

Weight:0.8 kg

Views:63

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6453/230-101 is a robust and highly sensitive eddy current displacement sensor designed for precise non-contact measurement of shaft displacement, vibration, and position. With a sensing tip diameter of 12.5 mm, this sensor is optimized for industrial applications requiring accurate monitoring of rotating machinery. Developed by Epro, a renowned manufacturer in the field of industrial condition monitoring, this model is compatible with various signal conditioners such as CON011 or CON021 and integrates seamlessly into comprehensive machine protection and diagnostic systems.

Constructed with a rugged stainless-steel body and engineered to withstand harsh environments, the PR6453/230-101 sensor ensures consistent performance under temperature fluctuations, oil exposure, and high mechanical stress, making it suitable for critical machinery in industries such as power generation, petrochemicals, and manufacturing.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | PR6453/230-101 |

| Sensing Principle | Eddy Current / Non-contact |

| Sensor Head Diameter | 12.5 mm |

| Measuring Range | ±1.0 mm to ±2.0 mm (depending on configuration) |

| Linear Range | 0.25 – 2.0 mm (target material dependent) |

| Sensitivity | Factory-calibrated to application range |

| Material (Housing) | Stainless Steel |

| Operating Temperature | -35°C to +180°C (sensor only) |

| Storage Temperature | -40°C to +200°C |

| Output Signal | Analog voltage (via CON011/CON021) |

| Connection Cable | Integrated coaxial cable |

| Mounting Type | Threaded sleeve (optional accessories available) |

| Protection Class | IP65 or higher (depending on installation) |

| Typical Target Material | Steel (AISI 4140 or equivalent) |

| Weight | 0.8 kg |

Applications

The PR6453/230-101 eddy current sensor is widely used across industries where high-precision shaft position and vibration monitoring are essential for safety, maintenance, and operational efficiency. Key application areas include:

Turbomachinery monitoring: Gas turbines, steam turbines, compressors

Pumps and motors: Monitoring shaft displacement and thermal expansion

Gearboxes and bearings: Vibration and misalignment detection

Condition monitoring systems: Integrated in Epro or third-party CMS platforms

Predictive maintenance: Early detection of wear, imbalance, and failure

OEM machinery integration: Embedded within critical rotating equipment

Advantages

Non-contact measurement: Prevents wear and allows continuous monitoring

High temperature resistance: Operates reliably in extreme environments

Robust construction: Designed for industrial use with stainless steel body

High accuracy and repeatability: Factory-calibrated to ensure consistency

Long service life: Minimal maintenance due to solid-state design

Seamless integration: Compatible with Epro CON011, CON021 signal converters

Compact design: Fits into tight installations and retrofitting scenarios

Vibration and shock resistant: Stable performance even under mechanical stress

Modular system: Easy to upgrade or replace in existing setups

Global support: Backed by Epro’s extensive technical network

FAQ

What is the measuring range of the PR6453/230-101 sensor?

It typically supports a linear range between 0.25 mm to 2.0 mm depending on the material and system setup.

Can this sensor be used at high temperatures?

Yes, the PR6453/230-101 can operate at temperatures up to 180°C, making it suitable for harsh environments.

What type of signal conditioner should I use with this sensor?

It is designed to work with Epro CON011 or CON021 converters.

Is the sensor compatible with non-ferromagnetic targets?

It is primarily calibrated for ferromagnetic materials like steel; accuracy may vary with other materials.

What kind of installation does the sensor require?

It typically mounts using threaded sleeves or brackets and requires proper alignment to the shaft or surface.

How long is the sensor’s standard cable?

Cable length can vary by order; standard versions come with fixed-length coaxial cables, customizable upon request.

Can this sensor detect shaft vibration and displacement simultaneously?

Yes, the sensor detects both parameters through the same analog signal depending on interpretation.

What certifications does this sensor have?

Typically, it complies with CE standards and may support ATEX/IECEx depending on configuration (verify with manufacturer).

Can this sensor be installed in a hazardous area?

Yes, when used with the appropriate certified converter and housing, it can be installed in classified zones.

Is recalibration necessary over time?

Not frequently. However, recalibration is advised during major maintenance intervals or system upgrades.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...