Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

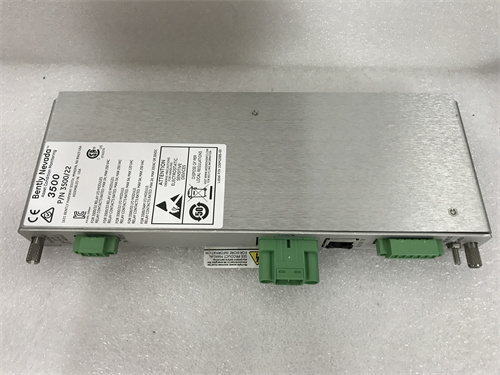

Bently Nevada 330103-00-06-05-02-CN 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-06-05-02-CN

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 0.5 meter

Weight:0.161kg

Views:17

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-06-05-02-CN is a high-performance 8 mm proximity probe from the 3300 XL series, specifically designed for advanced machinery condition monitoring and protection in harsh industrial environments. The “CN” suffix denotes a regional configuration intended for China or specific localization, but the probe retains full compatibility with the global 3300 XL system.

This model features a 6-meter probe with a 5-meter extension cable, making it suitable for extended installations while maintaining accuracy and high reliability. The probe measures the displacement and vibration of rotating machinery, offering critical insight into equipment health and allowing for predictive maintenance, minimizing downtime, and preventing catastrophic failures.

Key Features

8 mm sensing tip for precise measurement of shaft displacement

6-meter probe with a 5-meter extension cable, offering flexibility for various installations

-

High shock and vibration resistance for reliable operation in demanding environments

Eddy current technology providing non-contact, high-precision measurement

10-pin Bendix-style connector for secure and stable electrical connections

EMI/RFI shielding ensuring signal integrity even in electrically noisy environments

-

Stainless steel body providing high corrosion resistance and durability

-

Fully compatible with Bently Nevada 3300 XL Proximitor sensors for machinery protection

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330103-00-06-05-02-CN |

| Product Series | Bently Nevada 3300 XL |

| Probe Tip Diameter | 8 mm |

| Linear Measurement Range | ±1.0 mm (2.0 mm total displacement) |

| Sensing Range | 0.25 mm to 2.54 mm (0.010 in to 0.100 in) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) nominal |

| System Accuracy | ±0.07 mm (±0.0028 in) over linear range |

| Output Signal Type | Voltage proportional to gap distance |

| Mounting Thread | M10 × 1 mm |

| Connector Type | 10-pin Bendix-style male connector |

| Probe Cable Length | 6 meters |

| Extension Cable Length | 5 meters |

| Total System Length | 11 meters |

| Body Material | Stainless steel |

| Operating Temperature | -40 °C to +120 °C |

| Storage Temperature | -51 °C to +177 °C |

| Shock Limit | 500 g peak |

| Vibration Limit | 20 g, 10–2000 Hz |

| Environmental Protection | IP65 (when installed properly) |

| Dimensions | Total Length : 0.5 meter |

| Weight | 0.161 kg |

Typical Applications

Turbine Monitoring: Monitoring shaft vibration and axial displacement in turbine systems (gas, steam, and hydro)

Compressor and Motor Applications: Used for detecting misalignment, imbalance, and other issues in compressors and motors

Pump Diagnostics: Measuring shaft displacement to detect wear or failures in pumps and other critical process equipment

Condition Monitoring: Providing real-time feedback when integrated into 3300 XL Proximitor systems for continuous machinery health tracking

Predictive Maintenance: Essential for long-term reliability, reducing downtime, and improving overall maintenance schedules

Power Generation: Used in the monitoring of critical power generation equipment such as pumps, fans, and motors

Advantages

Extended Cable Length: The combination of a 6-meter probe and 5-meter extension cable makes it suitable for installations requiring long cable runs without compromising accuracy.

Precision and Reliability: The probe delivers high-accuracy measurements with non-contact sensing technology, reducing wear and tear.

Compatibility: Seamlessly integrates with the 3300 XL monitoring system and is backward compatible with earlier 3300 series components.

Durability: Built to withstand high shock and vibration levels, ensuring longevity and reliability in harsh industrial settings.

Signal Integrity: EMI/RFI shielding ensures stable signal output even in high electromagnetic interference environments.

Rugged Construction: Stainless steel housing provides protection against environmental factors like corrosion, dust, and moisture.

Ease of Use: The probe is designed for straightforward installation with an M10 × 1 mm threaded body and Bendix-style connector, ensuring quick setup and maintenance.

Frequently Asked Questions (FAQ)

What does the “CN” suffix mean in the part number?

The “CN” indicates a configuration optimized for specific regional markets, such as China, but it is still fully compatible with global 3300 XL systems.

What is the total length of the probe system?

The probe system, which includes the 6-meter probe and 5-meter extension cable, has a total length of 11 meters.

How accurate is this proximity probe?

The probe provides high accuracy with a tolerance of ±0.07 mm (±0.0028 in) over its linear range.

Is this probe suitable for use in hazardous areas?

The probe is rugged and can withstand harsh environments, but for use in hazardous locations, it is essential to ensure that the entire system meets required certifications.

Can the cable length be adjusted?

While this model comes with a fixed 6-meter probe and 5-meter extension cable, custom lengths are available upon request during ordering.

What is the mounting method for the probe?

The probe uses a M10 × 1 mm threaded mounting, ensuring secure and adjustable installation on various machinery.

What type of connector is used for this probe?

The probe uses a 10-pin Bendix-style male connector for secure and reliable signal transmission.

What is the typical operating temperature range for this probe?

It can operate within a temperature range of -40 °C to +120 °C.

What’s the probe’s shock limit?

The probe can withstand up to 500 g peak shock, making it suitable for high-vibration environments.

Can this probe be used with legacy 3300 series systems?

Yes, the probe is backward compatible with earlier 3300 series systems and integrates seamlessly with 3300 XL Proximitor sensors.

Bently Nevada 330103-00-06-05-02-CN 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-06-05-02-CN

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 0.5 meter

Weight:0.161kg

Views:17

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-06-05-02-CN is a high-performance 8 mm proximity probe from the 3300 XL series, specifically designed for advanced machinery condition monitoring and protection in harsh industrial environments. The “CN” suffix denotes a regional configuration intended for China or specific localization, but the probe retains full compatibility with the global 3300 XL system.

This model features a 6-meter probe with a 5-meter extension cable, making it suitable for extended installations while maintaining accuracy and high reliability. The probe measures the displacement and vibration of rotating machinery, offering critical insight into equipment health and allowing for predictive maintenance, minimizing downtime, and preventing catastrophic failures.

Key Features

8 mm sensing tip for precise measurement of shaft displacement

6-meter probe with a 5-meter extension cable, offering flexibility for various installations

-

High shock and vibration resistance for reliable operation in demanding environments

Eddy current technology providing non-contact, high-precision measurement

10-pin Bendix-style connector for secure and stable electrical connections

EMI/RFI shielding ensuring signal integrity even in electrically noisy environments

-

Stainless steel body providing high corrosion resistance and durability

-

Fully compatible with Bently Nevada 3300 XL Proximitor sensors for machinery protection

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330103-00-06-05-02-CN |

| Product Series | Bently Nevada 3300 XL |

| Probe Tip Diameter | 8 mm |

| Linear Measurement Range | ±1.0 mm (2.0 mm total displacement) |

| Sensing Range | 0.25 mm to 2.54 mm (0.010 in to 0.100 in) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) nominal |

| System Accuracy | ±0.07 mm (±0.0028 in) over linear range |

| Output Signal Type | Voltage proportional to gap distance |

| Mounting Thread | M10 × 1 mm |

| Connector Type | 10-pin Bendix-style male connector |

| Probe Cable Length | 6 meters |

| Extension Cable Length | 5 meters |

| Total System Length | 11 meters |

| Body Material | Stainless steel |

| Operating Temperature | -40 °C to +120 °C |

| Storage Temperature | -51 °C to +177 °C |

| Shock Limit | 500 g peak |

| Vibration Limit | 20 g, 10–2000 Hz |

| Environmental Protection | IP65 (when installed properly) |

| Dimensions | Total Length : 0.5 meter |

| Weight | 0.161 kg |

Typical Applications

Turbine Monitoring: Monitoring shaft vibration and axial displacement in turbine systems (gas, steam, and hydro)

Compressor and Motor Applications: Used for detecting misalignment, imbalance, and other issues in compressors and motors

Pump Diagnostics: Measuring shaft displacement to detect wear or failures in pumps and other critical process equipment

Condition Monitoring: Providing real-time feedback when integrated into 3300 XL Proximitor systems for continuous machinery health tracking

Predictive Maintenance: Essential for long-term reliability, reducing downtime, and improving overall maintenance schedules

Power Generation: Used in the monitoring of critical power generation equipment such as pumps, fans, and motors

Advantages

Extended Cable Length: The combination of a 6-meter probe and 5-meter extension cable makes it suitable for installations requiring long cable runs without compromising accuracy.

Precision and Reliability: The probe delivers high-accuracy measurements with non-contact sensing technology, reducing wear and tear.

Compatibility: Seamlessly integrates with the 3300 XL monitoring system and is backward compatible with earlier 3300 series components.

Durability: Built to withstand high shock and vibration levels, ensuring longevity and reliability in harsh industrial settings.

Signal Integrity: EMI/RFI shielding ensures stable signal output even in high electromagnetic interference environments.

Rugged Construction: Stainless steel housing provides protection against environmental factors like corrosion, dust, and moisture.

Ease of Use: The probe is designed for straightforward installation with an M10 × 1 mm threaded body and Bendix-style connector, ensuring quick setup and maintenance.

Frequently Asked Questions (FAQ)

What does the “CN” suffix mean in the part number?

The “CN” indicates a configuration optimized for specific regional markets, such as China, but it is still fully compatible with global 3300 XL systems.

What is the total length of the probe system?

The probe system, which includes the 6-meter probe and 5-meter extension cable, has a total length of 11 meters.

How accurate is this proximity probe?

The probe provides high accuracy with a tolerance of ±0.07 mm (±0.0028 in) over its linear range.

Is this probe suitable for use in hazardous areas?

The probe is rugged and can withstand harsh environments, but for use in hazardous locations, it is essential to ensure that the entire system meets required certifications.

Can the cable length be adjusted?

While this model comes with a fixed 6-meter probe and 5-meter extension cable, custom lengths are available upon request during ordering.

What is the mounting method for the probe?

The probe uses a M10 × 1 mm threaded mounting, ensuring secure and adjustable installation on various machinery.

What type of connector is used for this probe?

The probe uses a 10-pin Bendix-style male connector for secure and reliable signal transmission.

What is the typical operating temperature range for this probe?

It can operate within a temperature range of -40 °C to +120 °C.

What’s the probe’s shock limit?

The probe can withstand up to 500 g peak shock, making it suitable for high-vibration environments.

Can this probe be used with legacy 3300 series systems?

Yes, the probe is backward compatible with earlier 3300 series systems and integrates seamlessly with 3300 XL Proximitor sensors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...