Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

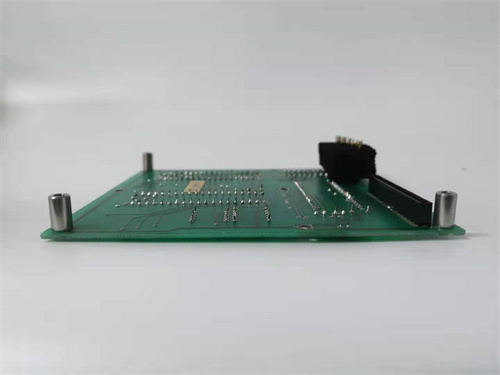

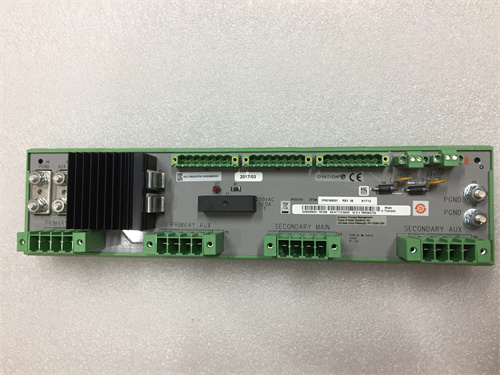

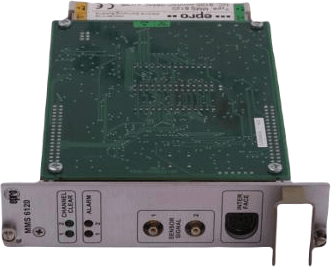

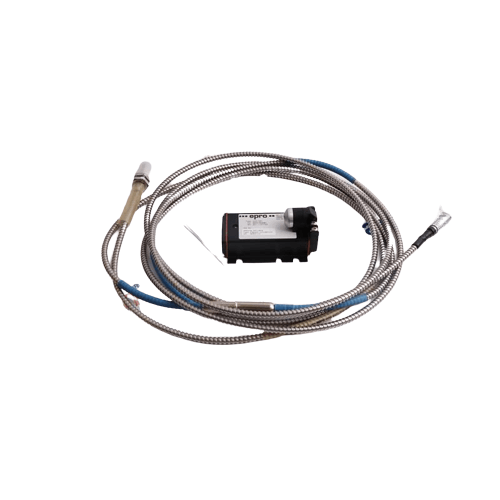

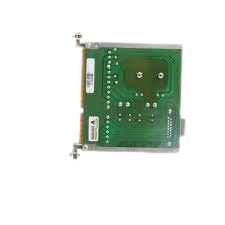

Emerson KJ4101X1-BA1 8-Wide Carrier

Manufacturer:Bently Nevada

Product Number:KJ4101X1-BA1

Product Type:8-Wide Carrier

Origin:USA

Dimensions:188 x 98 x 30 mm

Weight:0.18kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson KJ4101X1-BA1 8-Wide Carrier is a high-performance carrier module designed for the DeltaV™ distributed control system (DCS). It provides an efficient and organized platform for mounting I/O cards, ensuring optimal connectivity, stable performance, and simplified system integration in complex industrial environments.

With its compact design and robust construction, this carrier is engineered to support up to eight I/O channels while maintaining a lightweight and space-saving footprint. Its compatibility with multiple DeltaV™ system modules makes it a preferred choice for industries requiring high-density, reliable, and scalable I/O solutions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | KJ4101X1-BA1 |

| Type | 8-wide carrier for I/O module integration |

| Dimensions | 188 × 98 × 30 mm |

| Weight | 0.18 kg |

| Channel Capacity | Supports up to 8 I/O modules |

| Power Rating | 24 VDC nominal (system supplied) |

| Material | Industrial-grade, corrosion-resistant construction |

| Mounting | DIN-rail or panel-mounted installation |

| Operating Temperature | –20 °C to +70 °C |

| Humidity Tolerance | Up to 95% non-condensing |

| Certifications | CE, UL, RoHS compliant |

| Compatibility | Fully compatible with Emerson DeltaV™ I/O cards |

| Communication Support | High-speed internal backplane connection |

| Maintenance | Tool-free installation and removal |

Applications

Process Automation Systems – Facilitates seamless integration of I/O modules in large-scale automation setups.

Oil and Gas Plants – Supports reliable data communication and control operations in critical applications.

Power Generation – Ensures high-density module integration in turbine control and monitoring systems.

Chemical and Petrochemical Facilities – Provides dependable connections for hazardous area controls and process monitoring.

Water and Wastewater Treatment – Simplifies installation of analog and digital I/O for pumps, sensors, and valve controls.

Industrial Manufacturing – Ideal for production lines requiring high-accuracy, real-time data processing and control.

Advantages

High-Density Support – Accommodates up to 8 I/O modules in a single carrier, optimizing space usage.

Compact and Lightweight – Space-saving design allows easy integration into standard cabinets.

Superior Compatibility – Designed to work seamlessly with DeltaV™ DCS and other Emerson I/O systems.

Robust Construction – Industrial-grade materials ensure durability in demanding environments.

Ease of Installation – Supports DIN-rail or panel mounting with quick, tool-free setup.

Enhanced Reliability – Provides stable mechanical and electrical connections for critical applications.

Efficient Cable Management – Organized layout reduces wiring complexity and installation time.

Wide Environmental Tolerance – Performs reliably under harsh conditions, including high temperatures and humidity.

Reduced Downtime – Simplified maintenance and replacement processes improve operational efficiency.

Proven Performance – Extensively tested for long-term reliability in industrial automation systems.

FAQ

Q1: What is the primary function of the KJ4101X1-BA1 carrier?

A1: It serves as a platform to mount and connect up to eight I/O modules for DeltaV™ systems, ensuring stable communication and efficient power distribution.

Q2: Is the KJ4101X1-BA1 compatible with all DeltaV™ I/O cards?

A2: Yes, it is fully compatible with standard Emerson DeltaV™ I/O modules, both analog and digital.

Q3: Can the carrier support hot-swapping of modules?

A3: Yes, it supports hot-swapping of I/O modules without system downtime.

Q4: What is the operating temperature range for this carrier?

A4: The carrier operates reliably within –20 °C to +70 °C.

Q5: Does the carrier require additional tools for installation?

A5: No, it supports tool-free installation and maintenance, making setup and servicing easier.

Q6: How does the KJ4101X1-BA1 handle communication between modules?

A6: It uses a high-speed internal backplane connection to maintain efficient data communication between mounted I/O modules and the system controller.

Q7: What type of mounting does the KJ4101X1-BA1 support?

A7: It can be mounted on DIN rails or directly onto a control panel.

Q8: Is this carrier suitable for high-humidity environments?

A8: Yes, it is rated for up to 95% non-condensing humidity, ensuring reliable performance in challenging conditions.

Q9: Does the carrier provide surge protection for connected modules?

A9: While it is designed with stable connections, external surge protection should be implemented for optimal system safety.

Q10: Can the carrier be used in redundant system configurations?

A10: Yes, it integrates seamlessly with redundant system architectures for increased reliability in critical processes.

Emerson KJ4101X1-BA1 8-Wide Carrier

Manufacturer:Bently Nevada

Product Number:KJ4101X1-BA1

Product Type:8-Wide Carrier

Origin:USA

Dimensions:188 x 98 x 30 mm

Weight:0.18kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson KJ4101X1-BA1 8-Wide Carrier is a high-performance carrier module designed for the DeltaV™ distributed control system (DCS). It provides an efficient and organized platform for mounting I/O cards, ensuring optimal connectivity, stable performance, and simplified system integration in complex industrial environments.

With its compact design and robust construction, this carrier is engineered to support up to eight I/O channels while maintaining a lightweight and space-saving footprint. Its compatibility with multiple DeltaV™ system modules makes it a preferred choice for industries requiring high-density, reliable, and scalable I/O solutions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | KJ4101X1-BA1 |

| Type | 8-wide carrier for I/O module integration |

| Dimensions | 188 × 98 × 30 mm |

| Weight | 0.18 kg |

| Channel Capacity | Supports up to 8 I/O modules |

| Power Rating | 24 VDC nominal (system supplied) |

| Material | Industrial-grade, corrosion-resistant construction |

| Mounting | DIN-rail or panel-mounted installation |

| Operating Temperature | –20 °C to +70 °C |

| Humidity Tolerance | Up to 95% non-condensing |

| Certifications | CE, UL, RoHS compliant |

| Compatibility | Fully compatible with Emerson DeltaV™ I/O cards |

| Communication Support | High-speed internal backplane connection |

| Maintenance | Tool-free installation and removal |

Applications

Process Automation Systems – Facilitates seamless integration of I/O modules in large-scale automation setups.

Oil and Gas Plants – Supports reliable data communication and control operations in critical applications.

Power Generation – Ensures high-density module integration in turbine control and monitoring systems.

Chemical and Petrochemical Facilities – Provides dependable connections for hazardous area controls and process monitoring.

Water and Wastewater Treatment – Simplifies installation of analog and digital I/O for pumps, sensors, and valve controls.

Industrial Manufacturing – Ideal for production lines requiring high-accuracy, real-time data processing and control.

Advantages

High-Density Support – Accommodates up to 8 I/O modules in a single carrier, optimizing space usage.

Compact and Lightweight – Space-saving design allows easy integration into standard cabinets.

Superior Compatibility – Designed to work seamlessly with DeltaV™ DCS and other Emerson I/O systems.

Robust Construction – Industrial-grade materials ensure durability in demanding environments.

Ease of Installation – Supports DIN-rail or panel mounting with quick, tool-free setup.

Enhanced Reliability – Provides stable mechanical and electrical connections for critical applications.

Efficient Cable Management – Organized layout reduces wiring complexity and installation time.

Wide Environmental Tolerance – Performs reliably under harsh conditions, including high temperatures and humidity.

Reduced Downtime – Simplified maintenance and replacement processes improve operational efficiency.

Proven Performance – Extensively tested for long-term reliability in industrial automation systems.

FAQ

Q1: What is the primary function of the KJ4101X1-BA1 carrier?

A1: It serves as a platform to mount and connect up to eight I/O modules for DeltaV™ systems, ensuring stable communication and efficient power distribution.

Q2: Is the KJ4101X1-BA1 compatible with all DeltaV™ I/O cards?

A2: Yes, it is fully compatible with standard Emerson DeltaV™ I/O modules, both analog and digital.

Q3: Can the carrier support hot-swapping of modules?

A3: Yes, it supports hot-swapping of I/O modules without system downtime.

Q4: What is the operating temperature range for this carrier?

A4: The carrier operates reliably within –20 °C to +70 °C.

Q5: Does the carrier require additional tools for installation?

A5: No, it supports tool-free installation and maintenance, making setup and servicing easier.

Q6: How does the KJ4101X1-BA1 handle communication between modules?

A6: It uses a high-speed internal backplane connection to maintain efficient data communication between mounted I/O modules and the system controller.

Q7: What type of mounting does the KJ4101X1-BA1 support?

A7: It can be mounted on DIN rails or directly onto a control panel.

Q8: Is this carrier suitable for high-humidity environments?

A8: Yes, it is rated for up to 95% non-condensing humidity, ensuring reliable performance in challenging conditions.

Q9: Does the carrier provide surge protection for connected modules?

A9: While it is designed with stable connections, external surge protection should be implemented for optimal system safety.

Q10: Can the carrier be used in redundant system configurations?

A10: Yes, it integrates seamlessly with redundant system architectures for increased reliability in critical processes.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...