Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

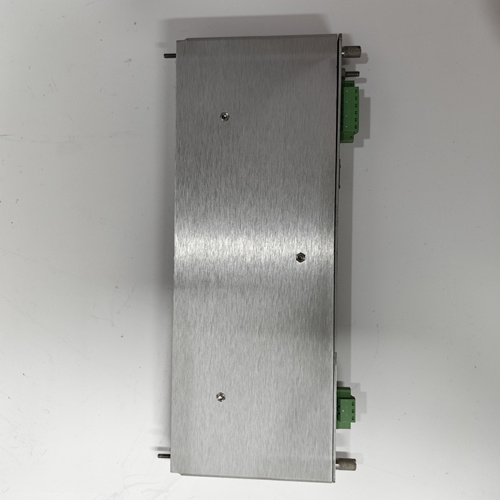

Bently Nevada 3500/40M 125680-01 Proximitor I/O Module

Manufacturer:Bently Nevada

Product Number:3500/40M 125680-01

Product Type:Proximitor I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 99.1 mm

Weight:0.2 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/40M 125680-01 Proximitor I/O Module is part of the 3500 Machinery Protection System, designed to interface with proximity transducers to monitor critical machine parameters such as radial vibration, thrust position, eccentricity, REBAM, and differential expansion. It processes and conditions the incoming signals, provides programmable alarm setpoints, and outputs essential operational and maintenance data for machinery protection and diagnostics.

Technical Specifications

| Parameter | Specification |

|---|---|

| Compatible Sensors | 1 to 4 proximity transducer signals |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ |

| Sensitivity | Radial Vibration: 3.94 mV/μm (100 mV/mil) or 7.87 mV/μm (200 mV/mil) |

| Output Impedance | 550 Ω |

| Transducer Power Supply | -24 VDC |

| Alarm Setpoints | User-configurable (0–100% of full scale) |

| Alarm Time Delay | 1–60 s (Alert), 0.1–60 s (Danger) |

| Operating Temperature | -30°C to +65°C (w/o internal barrier) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 95% non-condensing |

| Dimensions (I/O Module, non-barrier) | 241.3 x 24.4 x 99.1 mm |

| Weight (I/O Module, non-barrier) | 0.20 kg |

Applications

-

Continuous monitoring of critical machinery parameters in industrial environments

-

Protection of rotating equipment such as turbines, compressors, and pumps

-

Measurement of shaft vibration, position, and mechanical expansion

-

Integration with 3500 Rack Configuration Software for custom monitoring setups

-

Use in hazardous area classified zones with appropriate I/O module configurations

Advantages

High Versatility: Supports multiple monitoring functions including vibration, thrust, and REBAM in one module.

Configurable Channels: Allows programming of channel pairs for different functions.

Precision Monitoring: High accuracy of ±0.33% full scale typical.

Flexible Alarm Management: Programmable alert and danger levels with delay settings.

Durable Design: Suitable for harsh industrial environments and hazardous zones.

Seamless Integration: Compatible with the full Bently Nevada 3500 series platform.

FAQ

Q1: What is the main function of the 3500/40M 125680-01?

A1: It interfaces with proximity transducers to monitor machinery vibration, position, and other parameters while providing alarm functions.

Q2: How many channels does it support?

A2: It supports 4 channels, configured in pairs for up to two monitoring functions.

Q3: What sensors are compatible with this module?

A3: It is compatible with Bently Nevada proximity transducers.

Q4: Can it operate in hazardous environments?

A4: Yes, when used with specific I/O module options, it meets ATEX/IECEx/CSA approvals for hazardous areas.

Q5: What is the power consumption of the module?

A5: It consumes approximately 7.7 watts.

Q6: What is the physical size and weight?

A6: 241.3 x 24.4 x 99.1 mm and 0.20 kg.

Q7: Does it support buffered transducer outputs?

A7: Yes, it provides short-circuit-protected coaxial connectors for each channel.

Q8: What is the accuracy of its measurements?

A8: Typically ±0.33% of full scale, maximum ±1%.

Q9: How are alarm delays configured?

A9: Alarm delays are set through the 3500 Rack Configuration Software.

Q10: What are its primary industrial applications?

A10: It is mainly used for protection and monitoring of rotating machinery in industries such as power generation, oil and gas, and petrochemical.

Bently Nevada 3500/40M 125680-01 Proximitor I/O Module

Manufacturer:Bently Nevada

Product Number:3500/40M 125680-01

Product Type:Proximitor I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 99.1 mm

Weight:0.2 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/40M 125680-01 Proximitor I/O Module is part of the 3500 Machinery Protection System, designed to interface with proximity transducers to monitor critical machine parameters such as radial vibration, thrust position, eccentricity, REBAM, and differential expansion. It processes and conditions the incoming signals, provides programmable alarm setpoints, and outputs essential operational and maintenance data for machinery protection and diagnostics.

Technical Specifications

| Parameter | Specification |

|---|---|

| Compatible Sensors | 1 to 4 proximity transducer signals |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ |

| Sensitivity | Radial Vibration: 3.94 mV/μm (100 mV/mil) or 7.87 mV/μm (200 mV/mil) |

| Output Impedance | 550 Ω |

| Transducer Power Supply | -24 VDC |

| Alarm Setpoints | User-configurable (0–100% of full scale) |

| Alarm Time Delay | 1–60 s (Alert), 0.1–60 s (Danger) |

| Operating Temperature | -30°C to +65°C (w/o internal barrier) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 95% non-condensing |

| Dimensions (I/O Module, non-barrier) | 241.3 x 24.4 x 99.1 mm |

| Weight (I/O Module, non-barrier) | 0.20 kg |

Applications

-

Continuous monitoring of critical machinery parameters in industrial environments

-

Protection of rotating equipment such as turbines, compressors, and pumps

-

Measurement of shaft vibration, position, and mechanical expansion

-

Integration with 3500 Rack Configuration Software for custom monitoring setups

-

Use in hazardous area classified zones with appropriate I/O module configurations

Advantages

High Versatility: Supports multiple monitoring functions including vibration, thrust, and REBAM in one module.

Configurable Channels: Allows programming of channel pairs for different functions.

Precision Monitoring: High accuracy of ±0.33% full scale typical.

Flexible Alarm Management: Programmable alert and danger levels with delay settings.

Durable Design: Suitable for harsh industrial environments and hazardous zones.

Seamless Integration: Compatible with the full Bently Nevada 3500 series platform.

FAQ

Q1: What is the main function of the 3500/40M 125680-01?

A1: It interfaces with proximity transducers to monitor machinery vibration, position, and other parameters while providing alarm functions.

Q2: How many channels does it support?

A2: It supports 4 channels, configured in pairs for up to two monitoring functions.

Q3: What sensors are compatible with this module?

A3: It is compatible with Bently Nevada proximity transducers.

Q4: Can it operate in hazardous environments?

A4: Yes, when used with specific I/O module options, it meets ATEX/IECEx/CSA approvals for hazardous areas.

Q5: What is the power consumption of the module?

A5: It consumes approximately 7.7 watts.

Q6: What is the physical size and weight?

A6: 241.3 x 24.4 x 99.1 mm and 0.20 kg.

Q7: Does it support buffered transducer outputs?

A7: Yes, it provides short-circuit-protected coaxial connectors for each channel.

Q8: What is the accuracy of its measurements?

A8: Typically ±0.33% of full scale, maximum ±1%.

Q9: How are alarm delays configured?

A9: Alarm delays are set through the 3500 Rack Configuration Software.

Q10: What are its primary industrial applications?

A10: It is mainly used for protection and monitoring of rotating machinery in industries such as power generation, oil and gas, and petrochemical.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...