Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

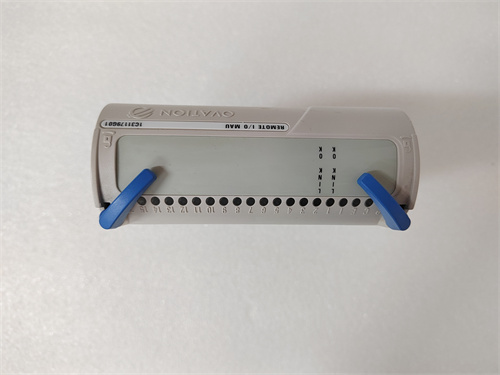

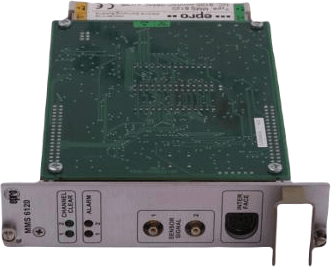

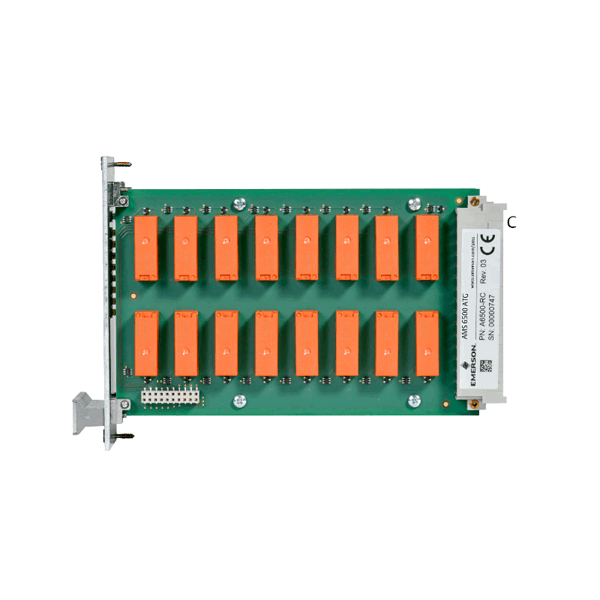

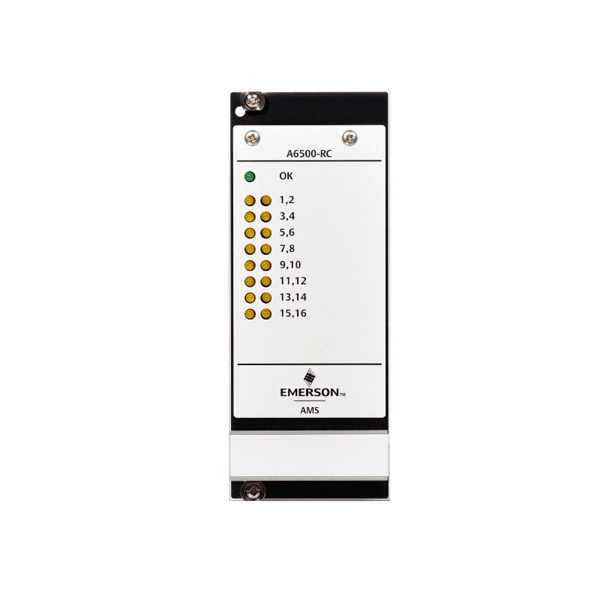

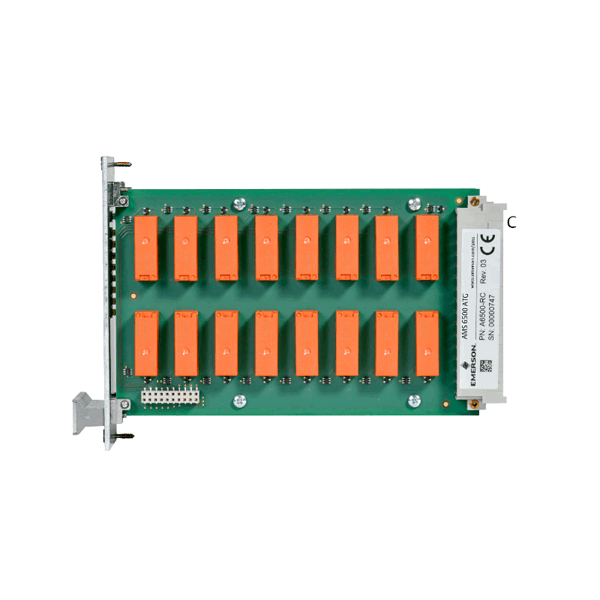

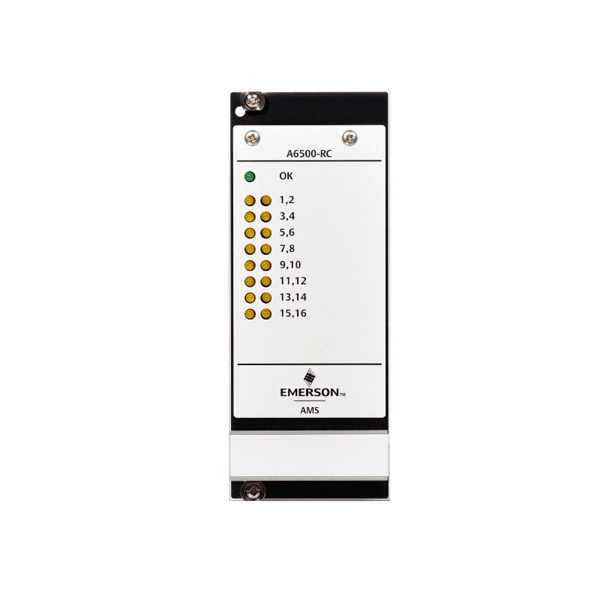

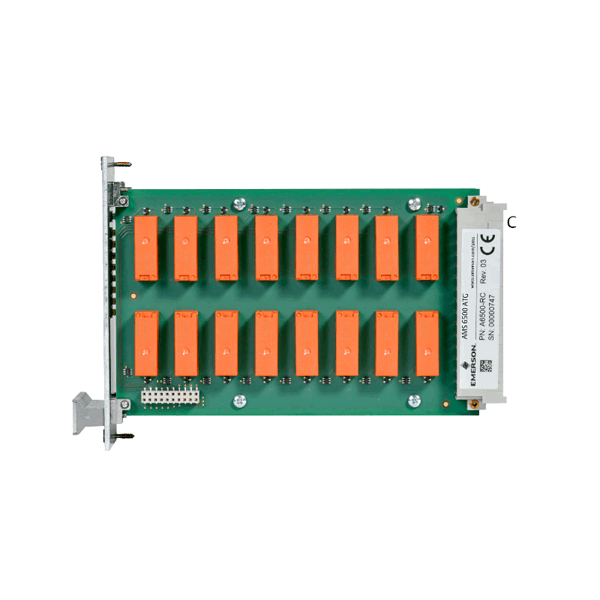

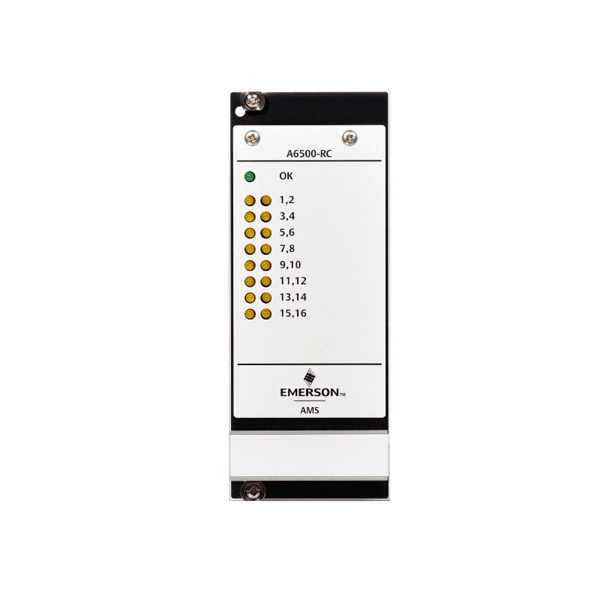

Emerson A6500-RC System Relay Card

Manufacturer: Emerson

Product Number:A6500-RC

Product Type:System Relay Card

Origin:USA

Dimensions:133.35 x 50.8 mm

Weight:0.42 kg

Views:97

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

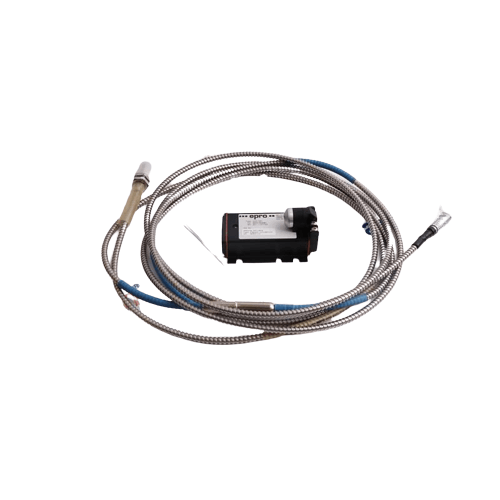

The Emerson A6500-RC is a System Relay Card designed for seamless integration within the AMS 6500 Machinery Health Monitor series. It plays a crucial role in real-time data acquisition, remote system monitoring, and machine condition analysis across various industrial environments.

By enabling remote connectivity and data transmission, the A6500-RC significantly enhances predictive maintenance strategies, helping industries reduce unplanned downtime and maintenance costs. It is widely used in power generation, oil & gas, petrochemical, and manufacturing sectors, where real-time monitoring is critical for operational efficiency.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Emerson |

| Product Series | AMS 6500 Machinery Health Monitor |

| Model Number | A6500-RC |

| Function | System Relay Card |

| Input/Output | Supports multiple wired and wireless interfaces |

| Communication Protocols | Modbus TCP/IP, OPC-UA, Ethernet, RS-485, and AMS Suite |

| Power Supply | 24V DC |

| Data Transfer Rate | High-speed real-time transmission |

| Remote Access | Secure access via industrial VPN and cloud integration |

| Operating Temperature | -20°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% – 95% (non-condensing) |

| Shock Resistance | IEC 60068-2-27 Compliant |

| Vibration Resistance | IEC 60068-2-6 Compliant |

| Dimensions | 133.35 x 50.8 mm |

| Weight | 0.42 kg |

Applications of Emerson A6500-RC

- Remote Machine Monitoring – Enables remote access to critical equipment in power plants, refineries, and factories.

- Industrial IoT Integration – Facilitates real-time machine health data collection for smart manufacturing.

- Oil & Gas Facilities – Helps monitor remote drilling rigs, pipelines, and offshore platforms.

- Chemical and Petrochemical Plants – Ensures safe and efficient operation of large-scale industrial processes.

- Steel & Metal Processing – Supports data-driven maintenance strategies in steel mills.

- Water & Wastewater Treatment – Improves control and monitoring of pumps, blowers, and turbines.

- Mining & Heavy Industry – Provides real-time vibration and temperature monitoring for mining equipment.

- Aerospace & Defense – Used for monitoring critical infrastructure in aerospace manufacturing and military applications.

- Automotive Industry – Ensures smooth operation of robotic production lines and assembly plants.

- Food & Beverage Processing – Enhances reliability of high-speed machinery and conveyors.

Advantages of Emerson A6500-RC

- Real-Time Remote Access – Enables remote monitoring and control from anywhere.

- Seamless Integration – Works with AMS 6500, Modbus, OPC-UA, and Ethernet-based systems.

- High-Speed Data Transfer – Ensures accurate and timely communication of machine health data.

- Industrial-Grade Security – Supports encrypted VPN and secure remote access.

- Reduces Maintenance Costs – Prevents unnecessary site visits by enabling remote diagnostics.

- Compact and Robust Design – Built for harsh industrial environments with shock and vibration resistance.

- Improves Decision-Making – Provides real-time alerts and predictive analytics for maintenance teams.

- Flexible Communication Options – Supports wired and wireless connections for enhanced versatility.

- Scalable and Modular – Can be customized and expanded based on plant requirements.

- Long-Term Reliability – Designed for continuous 24/7 operation in critical applications.

Emerson A6500-RC System Relay Card

Manufacturer: Emerson

Product Number:A6500-RC

Product Type:System Relay Card

Origin:USA

Dimensions:133.35 x 50.8 mm

Weight:0.42 kg

Views:97

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson A6500-RC is a System Relay Card designed for seamless integration within the AMS 6500 Machinery Health Monitor series. It plays a crucial role in real-time data acquisition, remote system monitoring, and machine condition analysis across various industrial environments.

By enabling remote connectivity and data transmission, the A6500-RC significantly enhances predictive maintenance strategies, helping industries reduce unplanned downtime and maintenance costs. It is widely used in power generation, oil & gas, petrochemical, and manufacturing sectors, where real-time monitoring is critical for operational efficiency.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Emerson |

| Product Series | AMS 6500 Machinery Health Monitor |

| Model Number | A6500-RC |

| Function | System Relay Card |

| Input/Output | Supports multiple wired and wireless interfaces |

| Communication Protocols | Modbus TCP/IP, OPC-UA, Ethernet, RS-485, and AMS Suite |

| Power Supply | 24V DC |

| Data Transfer Rate | High-speed real-time transmission |

| Remote Access | Secure access via industrial VPN and cloud integration |

| Operating Temperature | -20°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% – 95% (non-condensing) |

| Shock Resistance | IEC 60068-2-27 Compliant |

| Vibration Resistance | IEC 60068-2-6 Compliant |

| Dimensions | 133.35 x 50.8 mm |

| Weight | 0.42 kg |

Applications of Emerson A6500-RC

- Remote Machine Monitoring – Enables remote access to critical equipment in power plants, refineries, and factories.

- Industrial IoT Integration – Facilitates real-time machine health data collection for smart manufacturing.

- Oil & Gas Facilities – Helps monitor remote drilling rigs, pipelines, and offshore platforms.

- Chemical and Petrochemical Plants – Ensures safe and efficient operation of large-scale industrial processes.

- Steel & Metal Processing – Supports data-driven maintenance strategies in steel mills.

- Water & Wastewater Treatment – Improves control and monitoring of pumps, blowers, and turbines.

- Mining & Heavy Industry – Provides real-time vibration and temperature monitoring for mining equipment.

- Aerospace & Defense – Used for monitoring critical infrastructure in aerospace manufacturing and military applications.

- Automotive Industry – Ensures smooth operation of robotic production lines and assembly plants.

- Food & Beverage Processing – Enhances reliability of high-speed machinery and conveyors.

Advantages of Emerson A6500-RC

- Real-Time Remote Access – Enables remote monitoring and control from anywhere.

- Seamless Integration – Works with AMS 6500, Modbus, OPC-UA, and Ethernet-based systems.

- High-Speed Data Transfer – Ensures accurate and timely communication of machine health data.

- Industrial-Grade Security – Supports encrypted VPN and secure remote access.

- Reduces Maintenance Costs – Prevents unnecessary site visits by enabling remote diagnostics.

- Compact and Robust Design – Built for harsh industrial environments with shock and vibration resistance.

- Improves Decision-Making – Provides real-time alerts and predictive analytics for maintenance teams.

- Flexible Communication Options – Supports wired and wireless connections for enhanced versatility.

- Scalable and Modular – Can be customized and expanded based on plant requirements.

- Long-Term Reliability – Designed for continuous 24/7 operation in critical applications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...