Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

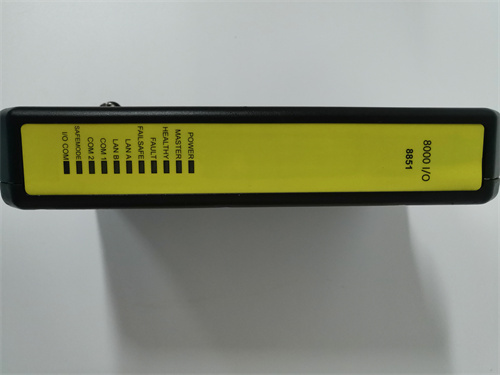

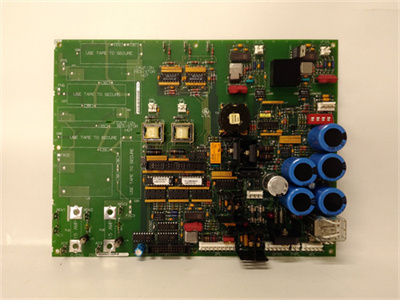

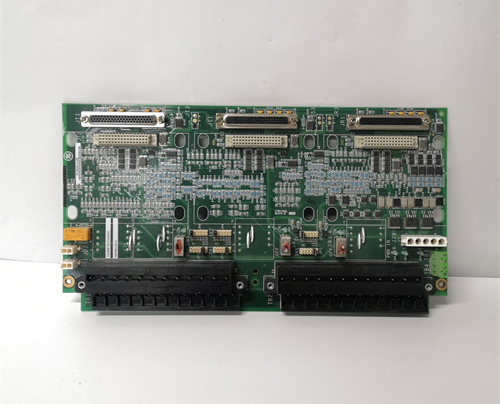

General Electric IC660BSM120 Bus Switching Module

Manufacturer:GE

Product Number:IC660BSM120

Product Type:Bus Switching Module

Origin:USA

Dimensions:123 x 71 x 116 mm

Weight:0.5 kg

Views:63

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC660BSM120 Bus Switching Module is a key component in the Genius I/O system, designed to enhance flexibility and reliability in distributed control systems. This module enables two independent I/O bus segments to be switched under user control or automatically based on bus failure conditions. Primarily utilized in redundant systems, the IC660BSM120 allows for automatic transfer to a backup bus without disrupting the system’s operation.

Engineered for industrial environments, it supports harsh conditions while maintaining optimal performance. The module ensures maximum uptime and continuous operation in critical control systems such as process automation, manufacturing, and infrastructure control.

Product Specifications

| Parameter | Details |

|---|---|

| Model | IC660BSM120 |

| Manufacturer | GE Automation & Controls (Genius Series) |

| Type | Bus Switching Module |

| Bus Type | Genius I/O Bus |

| Redundancy Support | Yes (Hot Backup Switching) |

| Operating Voltage | 5V DC (via Genius Bus Interface) |

| Current Consumption | Approx. 180 mA |

| Bus Cable Type | Shielded twisted-pair |

| Switching Time | < 1 ms |

| Module Mounting | DIN Rail or Panel Mount |

| Indicators | LED status indicators for bus condition |

| Environmental Rating | Suitable for industrial conditions |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% (non-condensing) |

| Dimensions (H x W x D) | 123 x 71 x 116 mm |

| Weight | 0.5 kg |

Product Applications

Industrial Automation: Seamless integration in process control environments where I/O reliability and redundancy are critical.

Redundant Systems: Enables failover switching between main and backup buses to maintain system operation during bus faults.

Power Generation & Utilities: Used in SCADA and DCS setups for high availability infrastructure.

Manufacturing Systems: Improves uptime in discrete and batch production lines with real-time data communication.

Transportation Networks: Integrated into control systems requiring fault-tolerant I/O communication.

Petrochemical Plants: Helps in hazardous environments where redundant communication paths are mandated.

Product Advantages

High Availability: Ensures automatic switching between buses to prevent communication loss during faults.

Robust Design: Built to withstand industrial environments with high EMI and temperature ranges.

Plug-and-Play Integration: Easily configured into existing Genius I/O networks without major rework.

Fast Switching Time: Transitions between buses in under 1 millisecond, ensuring no data loss.

Diagnostic LEDs: Front-panel indicators provide quick status insights for maintenance teams.

Maintenance-Free Operation: No moving parts or calibration needed, reducing long-term operational costs.

Frequently Asked Questions (FAQ)

What does the IC660BSM120 module do?

It provides automatic or manual switching between two Genius I/O buses in case of failure, enabling system redundancy.

Can it be used in hazardous or high-vibration environments?

Yes, it is designed to operate reliably in industrial-grade conditions including vibration, temperature extremes, and EMI.

Is the module hot-swappable?

No, the IC660BSM120 should be de-energized before replacement to avoid communication faults.

How does it detect a bus failure?

The module monitors bus signal integrity and status and automatically switches to the backup line if necessary.

Does it support DIN rail mounting?

Yes, it supports both DIN rail and panel mounting options.

What communication protocol does it support?

It uses the Genius I/O protocol over a shielded twisted-pair bus.

Can it be configured through a handheld programmer?

Yes, configuration and diagnostics can be accessed via GE Genius handheld or host tools.

What is the main benefit of using this module in a control system?

Improved system reliability through automatic communication path redundancy.

What happens if both buses fail?

The module will indicate the failure via LEDs, and the system may experience communication loss until restored.

Is firmware update required?

No regular firmware updates are required; the unit functions with factory firmware.

General Electric IC660BSM120 Bus Switching Module

Manufacturer:GE

Product Number:IC660BSM120

Product Type:Bus Switching Module

Origin:USA

Dimensions:123 x 71 x 116 mm

Weight:0.5 kg

Views:63

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC660BSM120 Bus Switching Module is a key component in the Genius I/O system, designed to enhance flexibility and reliability in distributed control systems. This module enables two independent I/O bus segments to be switched under user control or automatically based on bus failure conditions. Primarily utilized in redundant systems, the IC660BSM120 allows for automatic transfer to a backup bus without disrupting the system’s operation.

Engineered for industrial environments, it supports harsh conditions while maintaining optimal performance. The module ensures maximum uptime and continuous operation in critical control systems such as process automation, manufacturing, and infrastructure control.

Product Specifications

| Parameter | Details |

|---|---|

| Model | IC660BSM120 |

| Manufacturer | GE Automation & Controls (Genius Series) |

| Type | Bus Switching Module |

| Bus Type | Genius I/O Bus |

| Redundancy Support | Yes (Hot Backup Switching) |

| Operating Voltage | 5V DC (via Genius Bus Interface) |

| Current Consumption | Approx. 180 mA |

| Bus Cable Type | Shielded twisted-pair |

| Switching Time | < 1 ms |

| Module Mounting | DIN Rail or Panel Mount |

| Indicators | LED status indicators for bus condition |

| Environmental Rating | Suitable for industrial conditions |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% (non-condensing) |

| Dimensions (H x W x D) | 123 x 71 x 116 mm |

| Weight | 0.5 kg |

Product Applications

Industrial Automation: Seamless integration in process control environments where I/O reliability and redundancy are critical.

Redundant Systems: Enables failover switching between main and backup buses to maintain system operation during bus faults.

Power Generation & Utilities: Used in SCADA and DCS setups for high availability infrastructure.

Manufacturing Systems: Improves uptime in discrete and batch production lines with real-time data communication.

Transportation Networks: Integrated into control systems requiring fault-tolerant I/O communication.

Petrochemical Plants: Helps in hazardous environments where redundant communication paths are mandated.

Product Advantages

High Availability: Ensures automatic switching between buses to prevent communication loss during faults.

Robust Design: Built to withstand industrial environments with high EMI and temperature ranges.

Plug-and-Play Integration: Easily configured into existing Genius I/O networks without major rework.

Fast Switching Time: Transitions between buses in under 1 millisecond, ensuring no data loss.

Diagnostic LEDs: Front-panel indicators provide quick status insights for maintenance teams.

Maintenance-Free Operation: No moving parts or calibration needed, reducing long-term operational costs.

Frequently Asked Questions (FAQ)

What does the IC660BSM120 module do?

It provides automatic or manual switching between two Genius I/O buses in case of failure, enabling system redundancy.

Can it be used in hazardous or high-vibration environments?

Yes, it is designed to operate reliably in industrial-grade conditions including vibration, temperature extremes, and EMI.

Is the module hot-swappable?

No, the IC660BSM120 should be de-energized before replacement to avoid communication faults.

How does it detect a bus failure?

The module monitors bus signal integrity and status and automatically switches to the backup line if necessary.

Does it support DIN rail mounting?

Yes, it supports both DIN rail and panel mounting options.

What communication protocol does it support?

It uses the Genius I/O protocol over a shielded twisted-pair bus.

Can it be configured through a handheld programmer?

Yes, configuration and diagnostics can be accessed via GE Genius handheld or host tools.

What is the main benefit of using this module in a control system?

Improved system reliability through automatic communication path redundancy.

What happens if both buses fail?

The module will indicate the failure via LEDs, and the system may experience communication loss until restored.

Is firmware update required?

No regular firmware updates are required; the unit functions with factory firmware.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...