Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

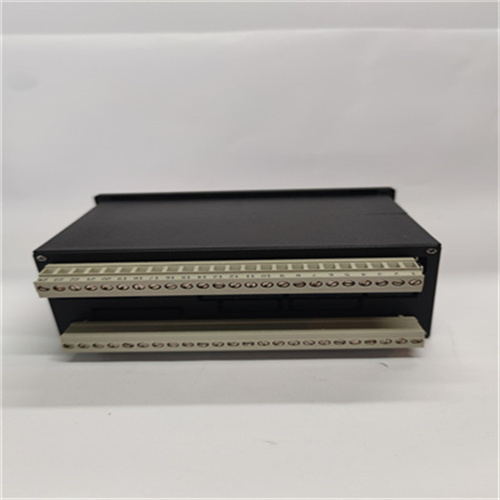

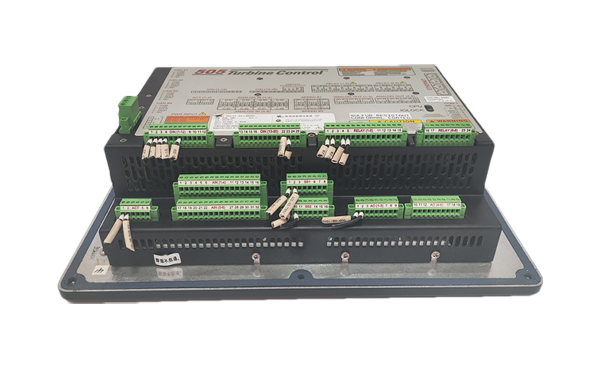

Woodward 9907-827 505 Speed Regulator

Manufacturer:Woodward

Product Number:9907-827

Product Type:505 Speed Regulator

Origin:USA

Dimensions:482.6 x 311 x 143 mm

Weight:4.13 kg

Views:62

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9907-827 is part of the highly respected 505 Series of steam turbine controllers, specifically designed to manage steam turbine speed and control in critical industrial applications. Known for its proven reliability and advanced control capability, the 9907-827 provides digital speed control, system integration, and user-friendly configuration options tailored to mechanical drive or generator turbine systems.

As a microprocessor-based governor, the 9907-827 incorporates flexible input/output (I/O) capabilities, comprehensive protection features, and a clear graphical interface. It offers seamless integration with plant Distributed Control Systems (DCS) or SCADA through Modbus communication. This model is ideal for operators and engineers seeking long-term stability, precision, and customization in turbine speed regulation and protection.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | Woodward 9907-827 |

| Series | 505 Steam Turbine Control |

| Control Type | Digital Speed Regulator |

| Application | Single-valve, single-extraction steam turbines |

| Display Interface | Graphical LCD Touchscreen |

| Power Supply | 18–32 VDC (Nominal: 24 VDC) |

| Communication Protocol | Modbus RTU (RS-232 / RS-485) |

| Analog Inputs | 4–20 mA, ±5 VDC, ±10 VDC |

| Analog Outputs | 4–20 mA, configurable |

| Discrete Inputs / Outputs | Configurable Dry Contact I/O |

| Operating Temperature Range | -25°C to +70°C |

| Protection Class | NEMA 4X / IP66 (front panel) |

| Configuration Method | Front panel or remote upload (USB/Ethernet) |

| Mounting | Panel Mount |

| Certifications | CE, CSA, UL, RoHS Compliant |

| Dimensions (H × W × D) | 482.6 x 311 x 143 mm |

| Weight | 4.13 kg |

Product Applications

The Woodward 9907-827 is built for a wide range of steam turbine speed regulation and protection tasks, especially where digital precision and integration with plant-wide systems is required. Key application areas include:

Industrial Steam Turbines driving compressors, pumps, or fans

Power Generation Units, including cogeneration and standby power systems

Petrochemical and Refining Plants requiring reliable process steam control

Paper Mills and Textile Plants using mechanical drive turbines

Sugar and Ethanol Industries where steam turbines power process equipment

Turbines with Single Extraction or Admission Valves

Product Advantages

Integrated Speed Control and Protection: Combines governing, overspeed, and load control in one compact unit.

User-Friendly Interface: Equipped with a large graphical touchscreen for local operation and diagnostics.

Highly Configurable I/O: Supports diverse input types and offers flexibility for field wiring.

Communication Flexibility: Modbus RTU (RS-232/485) allows seamless connection to DCS or SCADA systems.

Robust and Durable Design: Built to handle harsh industrial conditions with wide temperature tolerance.

Advanced Logic Programming: Supports custom logic and sequencing without external PLCs.

Remote Configuration and Monitoring: Upload and modify configurations using a PC or Ethernet connection.

Reliable Startup and Shutdown Management: Programmable start-up, cool-down, and trip sequences ensure smooth transitions.

Fail-Safe Operation: Includes watchdog timers, sensor diagnostics, and secure password protection.

CE and UL Compliance: Certified for industrial use with international standards adherence.

Frequently Asked Questions (FAQ)

What is the primary use of the 9907-827 controller?

It is used for precise speed control of single-valve steam turbines in industrial or utility applications.

Can this controller integrate with DCS systems?

Yes, it supports Modbus RTU via RS-232 or RS-485 for seamless DCS/SCADA integration.

How is the controller configured?

The unit can be configured through its front-panel touchscreen or remotely via USB or Ethernet.

Does it support analog signal inputs?

Yes, it supports 4–20 mA, ±5 VDC, and ±10 VDC analog inputs for sensors and command signals.

Is it compatible with extraction/admission turbines?

Yes, it supports control of single extraction or admission valve turbines.

What protections does the system provide?

The controller offers overspeed protection, limit monitoring, and customizable trip logic.

What is the front panel rating?

The front panel meets NEMA 4X/IP66 standards, providing water and dust resistance.

What are the dimensions and weight of the unit?

It measures 482.6 x 311 x 143 mm and weighs 4.13 kg.

Is the unit suitable for outdoor installation?

It is designed for panel mounting indoors, but the front panel protection allows it to be installed in harsh industrial environments.

Can logic functions be customized?

Yes, advanced programming capabilities allow the implementation of custom sequences and logic without external controllers.

Woodward 9907-827 505 Speed Regulator

Manufacturer:Woodward

Product Number:9907-827

Product Type:505 Speed Regulator

Origin:USA

Dimensions:482.6 x 311 x 143 mm

Weight:4.13 kg

Views:62

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9907-827 is part of the highly respected 505 Series of steam turbine controllers, specifically designed to manage steam turbine speed and control in critical industrial applications. Known for its proven reliability and advanced control capability, the 9907-827 provides digital speed control, system integration, and user-friendly configuration options tailored to mechanical drive or generator turbine systems.

As a microprocessor-based governor, the 9907-827 incorporates flexible input/output (I/O) capabilities, comprehensive protection features, and a clear graphical interface. It offers seamless integration with plant Distributed Control Systems (DCS) or SCADA through Modbus communication. This model is ideal for operators and engineers seeking long-term stability, precision, and customization in turbine speed regulation and protection.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | Woodward 9907-827 |

| Series | 505 Steam Turbine Control |

| Control Type | Digital Speed Regulator |

| Application | Single-valve, single-extraction steam turbines |

| Display Interface | Graphical LCD Touchscreen |

| Power Supply | 18–32 VDC (Nominal: 24 VDC) |

| Communication Protocol | Modbus RTU (RS-232 / RS-485) |

| Analog Inputs | 4–20 mA, ±5 VDC, ±10 VDC |

| Analog Outputs | 4–20 mA, configurable |

| Discrete Inputs / Outputs | Configurable Dry Contact I/O |

| Operating Temperature Range | -25°C to +70°C |

| Protection Class | NEMA 4X / IP66 (front panel) |

| Configuration Method | Front panel or remote upload (USB/Ethernet) |

| Mounting | Panel Mount |

| Certifications | CE, CSA, UL, RoHS Compliant |

| Dimensions (H × W × D) | 482.6 x 311 x 143 mm |

| Weight | 4.13 kg |

Product Applications

The Woodward 9907-827 is built for a wide range of steam turbine speed regulation and protection tasks, especially where digital precision and integration with plant-wide systems is required. Key application areas include:

Industrial Steam Turbines driving compressors, pumps, or fans

Power Generation Units, including cogeneration and standby power systems

Petrochemical and Refining Plants requiring reliable process steam control

Paper Mills and Textile Plants using mechanical drive turbines

Sugar and Ethanol Industries where steam turbines power process equipment

Turbines with Single Extraction or Admission Valves

Product Advantages

Integrated Speed Control and Protection: Combines governing, overspeed, and load control in one compact unit.

User-Friendly Interface: Equipped with a large graphical touchscreen for local operation and diagnostics.

Highly Configurable I/O: Supports diverse input types and offers flexibility for field wiring.

Communication Flexibility: Modbus RTU (RS-232/485) allows seamless connection to DCS or SCADA systems.

Robust and Durable Design: Built to handle harsh industrial conditions with wide temperature tolerance.

Advanced Logic Programming: Supports custom logic and sequencing without external PLCs.

Remote Configuration and Monitoring: Upload and modify configurations using a PC or Ethernet connection.

Reliable Startup and Shutdown Management: Programmable start-up, cool-down, and trip sequences ensure smooth transitions.

Fail-Safe Operation: Includes watchdog timers, sensor diagnostics, and secure password protection.

CE and UL Compliance: Certified for industrial use with international standards adherence.

Frequently Asked Questions (FAQ)

What is the primary use of the 9907-827 controller?

It is used for precise speed control of single-valve steam turbines in industrial or utility applications.

Can this controller integrate with DCS systems?

Yes, it supports Modbus RTU via RS-232 or RS-485 for seamless DCS/SCADA integration.

How is the controller configured?

The unit can be configured through its front-panel touchscreen or remotely via USB or Ethernet.

Does it support analog signal inputs?

Yes, it supports 4–20 mA, ±5 VDC, and ±10 VDC analog inputs for sensors and command signals.

Is it compatible with extraction/admission turbines?

Yes, it supports control of single extraction or admission valve turbines.

What protections does the system provide?

The controller offers overspeed protection, limit monitoring, and customizable trip logic.

What is the front panel rating?

The front panel meets NEMA 4X/IP66 standards, providing water and dust resistance.

What are the dimensions and weight of the unit?

It measures 482.6 x 311 x 143 mm and weighs 4.13 kg.

Is the unit suitable for outdoor installation?

It is designed for panel mounting indoors, but the front panel protection allows it to be installed in harsh industrial environments.

Can logic functions be customized?

Yes, advanced programming capabilities allow the implementation of custom sequences and logic without external controllers.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...