Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

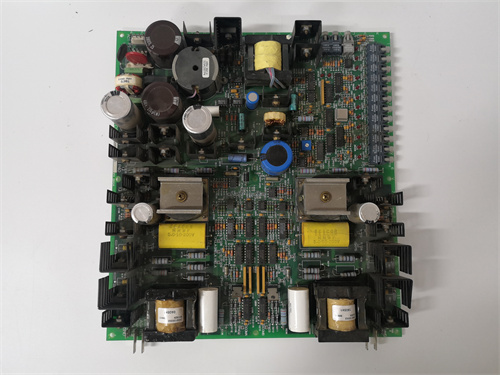

General Electric IS200FCGDH1B Mark VI Control Board

Manufacturer:GE

Product Number:IS200FCGDH1B

Product Type:Mark VI Control Board

Origin:USA

Dimensions:315 x 265 x 51 mm

Weight:0.3 kg

Views:22

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200FCGDH1B is a high-performance Mark VI Control Board designed by General Electric for turbine control and automation systems. As part of the Mark VI Turbine Control System, this board plays a crucial role in digital signal processing, managing feedback loops, coordinating system diagnostics, and maintaining turbine safety and efficiency.

The Mark VI system, known for its modular architecture and robustness, integrates seamlessly with gas, steam, and hydro turbines, supporting both Simple Cycle and Combined Cycle configurations. The IS200FCGDH1B board provides reliable functionality for fuel gas control, generator control, and I/O processing. Its design is optimized for harsh industrial environments, ensuring long-term operational stability with low maintenance.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | IS200FCGDH1B |

| Manufacturer | GE (General Electric) |

| Series | Mark VI Speedtronic |

| Function | Fuel Gas Control Board |

| Type | PCB Module |

| Communication Protocol | Ethernet, RS-232, RS-485 (via system interface) |

| Power Supply Input | 28V DC typical |

| Connector Type | Backplane plug-in |

| Mounting Type | Rack-Mounted |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Conformal Coating | Yes (for harsh environment protection) |

| Dimensions | 315 x 265 x 51 mm |

| Weight | 0.3 kg |

| Compliance | CE, RoHS, UL Certified |

| Diagnostic Features | Embedded LED indicators, self-test routines |

| Firmware Compatibility | Mark VI native software, ControlST suite |

| Status LEDs | Yes (Power, Fault, Communication indicators) |

Product Applications

The IS200FCGDH1B board is widely used across various industrial environments where high-reliability turbine control is essential. Its core applications include:

Gas and Steam Turbine Control Systems

Fuel Gas Valve Management

Rotational Speed Feedback and Control

Industrial Power Generation Automation

Boiler Turbine Generator (BTG) Units

Combined Cycle Power Plants

Marine Propulsion Systems (GE LM Series)

It is typically mounted in control cabinets, interfacing with processors, I/O modules, and terminal boards to deliver precision control over mechanical-electrical conversion processes.

Product Advantages

High Reliability in Harsh Conditions

Designed to operate under extreme temperature, vibration, and humidity, the IS200FCGDH1B is conformally coated for rugged field applications.

Part of a Proven Architecture

As part of the GE Mark VI platform, it benefits from GE’s decades of experience in turbine automation and control logic engineering.

Efficient Signal Handling

Offers efficient data acquisition and processing for fuel gas parameters, delivering real-time control with minimal latency.

Advanced Diagnostics

Integrated self-monitoring and diagnostic LEDs simplify troubleshooting and predictive maintenance.

Ease of Integration

Seamlessly integrates into existing Mark VI or Mark VIe systems, reducing retrofit cost and engineering effort.

Longevity and Support

Supported by a global network of GE field engineers and service centers, with ongoing firmware updates and lifecycle support.

FAQ

What type of signal conditioning does the IS200FCGDH1B support?

It supports analog and discrete signal conditioning tailored for fuel gas control applications.

Can the board interface with external HART-enabled devices?

While the board itself doesn’t directly support HART, it can connect to HART devices through compatible I/O modules in the Mark VI system.

How is the board configured within the Mark VI system?

Configuration is done via the ControlST software suite, allowing engineers to define logic, I/O mappings, and diagnostics.

Does the IS200FCGDH1B support redundant architecture?

Yes, it supports operation in dual and triple modular redundancy (TMR) architectures for high-availability applications.

What is the isolation voltage between channels?

Isolation voltage is rated at 1500V between signal and ground for safe field-device interface.

What kind of feedback does it process?

It handles thermocouple, RTD, 4–20mA, and pressure transducer feedback depending on system configuration.

What happens if the board fails during operation?

The Mark VI system’s redundancy and failover logic ensure that control is handed off to a backup module with minimal disruption.

Is firmware upgradeable on this board?

Yes, firmware upgrades are supported via ControlST or ToolboxST using GE-certified update files.

How is fault data logged and retrieved?

Faults are logged locally on the controller and retrievable via the GE diagnostic interface or remote HMI systems.

Can the board operate standalone or does it require a full rack system?

It requires integration within a full Mark VI or Mark VIe rack system to function properly.

General Electric IS200FCGDH1B Mark VI Control Board

Manufacturer:GE

Product Number:IS200FCGDH1B

Product Type:Mark VI Control Board

Origin:USA

Dimensions:315 x 265 x 51 mm

Weight:0.3 kg

Views:22

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200FCGDH1B is a high-performance Mark VI Control Board designed by General Electric for turbine control and automation systems. As part of the Mark VI Turbine Control System, this board plays a crucial role in digital signal processing, managing feedback loops, coordinating system diagnostics, and maintaining turbine safety and efficiency.

The Mark VI system, known for its modular architecture and robustness, integrates seamlessly with gas, steam, and hydro turbines, supporting both Simple Cycle and Combined Cycle configurations. The IS200FCGDH1B board provides reliable functionality for fuel gas control, generator control, and I/O processing. Its design is optimized for harsh industrial environments, ensuring long-term operational stability with low maintenance.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | IS200FCGDH1B |

| Manufacturer | GE (General Electric) |

| Series | Mark VI Speedtronic |

| Function | Fuel Gas Control Board |

| Type | PCB Module |

| Communication Protocol | Ethernet, RS-232, RS-485 (via system interface) |

| Power Supply Input | 28V DC typical |

| Connector Type | Backplane plug-in |

| Mounting Type | Rack-Mounted |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Conformal Coating | Yes (for harsh environment protection) |

| Dimensions | 315 x 265 x 51 mm |

| Weight | 0.3 kg |

| Compliance | CE, RoHS, UL Certified |

| Diagnostic Features | Embedded LED indicators, self-test routines |

| Firmware Compatibility | Mark VI native software, ControlST suite |

| Status LEDs | Yes (Power, Fault, Communication indicators) |

Product Applications

The IS200FCGDH1B board is widely used across various industrial environments where high-reliability turbine control is essential. Its core applications include:

Gas and Steam Turbine Control Systems

Fuel Gas Valve Management

Rotational Speed Feedback and Control

Industrial Power Generation Automation

Boiler Turbine Generator (BTG) Units

Combined Cycle Power Plants

Marine Propulsion Systems (GE LM Series)

It is typically mounted in control cabinets, interfacing with processors, I/O modules, and terminal boards to deliver precision control over mechanical-electrical conversion processes.

Product Advantages

High Reliability in Harsh Conditions

Designed to operate under extreme temperature, vibration, and humidity, the IS200FCGDH1B is conformally coated for rugged field applications.

Part of a Proven Architecture

As part of the GE Mark VI platform, it benefits from GE’s decades of experience in turbine automation and control logic engineering.

Efficient Signal Handling

Offers efficient data acquisition and processing for fuel gas parameters, delivering real-time control with minimal latency.

Advanced Diagnostics

Integrated self-monitoring and diagnostic LEDs simplify troubleshooting and predictive maintenance.

Ease of Integration

Seamlessly integrates into existing Mark VI or Mark VIe systems, reducing retrofit cost and engineering effort.

Longevity and Support

Supported by a global network of GE field engineers and service centers, with ongoing firmware updates and lifecycle support.

FAQ

What type of signal conditioning does the IS200FCGDH1B support?

It supports analog and discrete signal conditioning tailored for fuel gas control applications.

Can the board interface with external HART-enabled devices?

While the board itself doesn’t directly support HART, it can connect to HART devices through compatible I/O modules in the Mark VI system.

How is the board configured within the Mark VI system?

Configuration is done via the ControlST software suite, allowing engineers to define logic, I/O mappings, and diagnostics.

Does the IS200FCGDH1B support redundant architecture?

Yes, it supports operation in dual and triple modular redundancy (TMR) architectures for high-availability applications.

What is the isolation voltage between channels?

Isolation voltage is rated at 1500V between signal and ground for safe field-device interface.

What kind of feedback does it process?

It handles thermocouple, RTD, 4–20mA, and pressure transducer feedback depending on system configuration.

What happens if the board fails during operation?

The Mark VI system’s redundancy and failover logic ensure that control is handed off to a backup module with minimal disruption.

Is firmware upgradeable on this board?

Yes, firmware upgrades are supported via ControlST or ToolboxST using GE-certified update files.

How is fault data logged and retrieved?

Faults are logged locally on the controller and retrievable via the GE diagnostic interface or remote HMI systems.

Can the board operate standalone or does it require a full rack system?

It requires integration within a full Mark VI or Mark VIe rack system to function properly.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...