Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

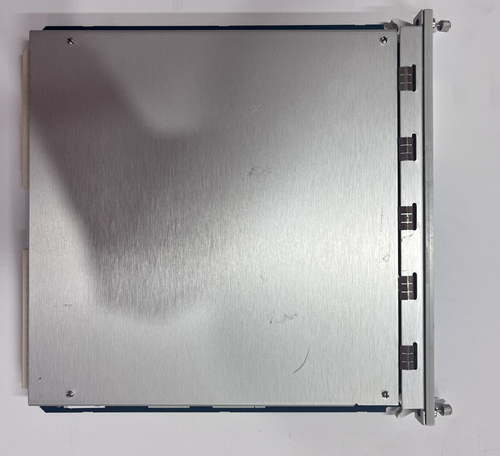

Bently Nevada 330104-00-08-05-01-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-00-08-05-01-05

Product Type:3300 XL 8 mm Proximity Probe (Metric)

Origin:USA

Total Length:0.5 meter

Weight:0.161kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-08-05-01-05 is a metric proximity probe from the 3300 XL 8 mm series, designed for accurate non-contact vibration and position sensing in industrial rotating machinery. As a vital component in condition monitoring and machinery protection systems, this probe is engineered to deliver high precision and long-term reliability, even in harsh industrial environments.

The 330104-00-08-05-01-05 model features an 8 mm diameter probe tip, a 0.5-meter cable length, and is optimized for use with Bently Nevada’s 3300 XL extension cables and Proximitor® sensors. It is constructed with durable materials and adheres to industry standards like API 670, ensuring compatibility and ruggedness for mission-critical operations.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330104-00-08-05-01-05 |

| Series | 3300 XL 8 mm |

| Sensing Principle | Eddy Current |

| Tip Diameter | 8 mm |

| Probe Material | AISI 304 Stainless Steel |

| Thread Type | M10 x 1.0 |

| Thread Length | 25 mm |

| Mounting Length | 45 mm |

| Cable Length | 0.5 meter |

| Connector Type | 90° Angle Male Coaxial Connector |

| Temperature Range | -35°C to +177°C |

| Environmental Protection | IP68 |

| System Compatibility | 3300 XL Extension Cable & Proximitor Sensor |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

Applications

The 330104-00-08-05-01-05 is tailored for demanding machinery monitoring applications across a variety of sectors, including:

Power Generation: Turbines and generators for shaft vibration and radial position monitoring

Oil & Gas: Compressors, centrifugal pumps, and turbo expanders

Petrochemical Industry: Monitoring gearboxes and rotating reactors

Marine & Offshore: Diesel engines and high-speed turbines

Steel & Paper Mills: Roll stands and high-speed fans

Manufacturing Plants: CNC machines and rotating test beds

Its compact cable length and angled connector make it ideal for installations in space-restricted environments.

Product Advantages

High Precision and Stability: Designed with robust linear response over a broad gap range, offering excellent measurement accuracy for displacement and vibration.

Superior Environmental Resistance: IP68-rated stainless steel construction allows continuous operation in oil, dust, and high-humidity conditions.

Compact Installation Profile: 0.5-meter cable and right-angle connector enable mounting in tight or obstructed machine compartments.

Long-Term Durability: Proven field performance over extended operational cycles in high-speed rotating machinery.

Compliant with Global Standards: Fully supports ISO and API 670 guidelines for rotating equipment protection.

Plug-and-Play Compatibility: Fully interoperable with other 3300 XL system components, ensuring easy installation and calibration-free operation.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of this probe?

A1: It measures the distance between the probe tip and a rotating shaft to monitor vibration or position changes in real time.

Q2: What does the “0.5 meter” cable length mean?

A2: It is the total length of the permanently attached coaxial cable from the probe tip to the angled connector.

Q3: Can this probe be submerged in oil or coolant?

A3: Yes, with its IP68 rating and stainless-steel construction, it is built to withstand immersion in lubricants and fluids.

Q4: What sensor should I use with this probe?

A4: It is designed to be used with Bently Nevada 3300 XL Proximitor® sensors for optimal performance.

Q5: Is the probe suitable for high-temperature environments?

A5: Yes, it is rated to operate in environments ranging from -35°C up to +177°C.

Q6: How do I verify correct installation depth?

A6: Use a calibrated mechanical spacer tool or a dial indicator to ensure the specified probe-to-target gap.

Q7: Will the probe work if mounted near a magnetic field?

A7: Magnetic fields should be avoided, as they can interfere with eddy current measurements.

Q8: What is the benefit of the 90-degree connector?

A8: It simplifies installation in confined spaces and provides strain relief for cable routing.

Q9: Does the probe require recalibration?

A9: No, once installed with compatible hardware, the system is factory calibrated and does not need field calibration.

Q10: What is the typical lifespan of this probe?

A10: When used within specified limits, the probe typically lasts for years without performance degradation.

Bently Nevada 330104-00-08-05-01-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-00-08-05-01-05

Product Type:3300 XL 8 mm Proximity Probe (Metric)

Origin:USA

Total Length:0.5 meter

Weight:0.161kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-08-05-01-05 is a metric proximity probe from the 3300 XL 8 mm series, designed for accurate non-contact vibration and position sensing in industrial rotating machinery. As a vital component in condition monitoring and machinery protection systems, this probe is engineered to deliver high precision and long-term reliability, even in harsh industrial environments.

The 330104-00-08-05-01-05 model features an 8 mm diameter probe tip, a 0.5-meter cable length, and is optimized for use with Bently Nevada’s 3300 XL extension cables and Proximitor® sensors. It is constructed with durable materials and adheres to industry standards like API 670, ensuring compatibility and ruggedness for mission-critical operations.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330104-00-08-05-01-05 |

| Series | 3300 XL 8 mm |

| Sensing Principle | Eddy Current |

| Tip Diameter | 8 mm |

| Probe Material | AISI 304 Stainless Steel |

| Thread Type | M10 x 1.0 |

| Thread Length | 25 mm |

| Mounting Length | 45 mm |

| Cable Length | 0.5 meter |

| Connector Type | 90° Angle Male Coaxial Connector |

| Temperature Range | -35°C to +177°C |

| Environmental Protection | IP68 |

| System Compatibility | 3300 XL Extension Cable & Proximitor Sensor |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

Applications

The 330104-00-08-05-01-05 is tailored for demanding machinery monitoring applications across a variety of sectors, including:

Power Generation: Turbines and generators for shaft vibration and radial position monitoring

Oil & Gas: Compressors, centrifugal pumps, and turbo expanders

Petrochemical Industry: Monitoring gearboxes and rotating reactors

Marine & Offshore: Diesel engines and high-speed turbines

Steel & Paper Mills: Roll stands and high-speed fans

Manufacturing Plants: CNC machines and rotating test beds

Its compact cable length and angled connector make it ideal for installations in space-restricted environments.

Product Advantages

High Precision and Stability: Designed with robust linear response over a broad gap range, offering excellent measurement accuracy for displacement and vibration.

Superior Environmental Resistance: IP68-rated stainless steel construction allows continuous operation in oil, dust, and high-humidity conditions.

Compact Installation Profile: 0.5-meter cable and right-angle connector enable mounting in tight or obstructed machine compartments.

Long-Term Durability: Proven field performance over extended operational cycles in high-speed rotating machinery.

Compliant with Global Standards: Fully supports ISO and API 670 guidelines for rotating equipment protection.

Plug-and-Play Compatibility: Fully interoperable with other 3300 XL system components, ensuring easy installation and calibration-free operation.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of this probe?

A1: It measures the distance between the probe tip and a rotating shaft to monitor vibration or position changes in real time.

Q2: What does the “0.5 meter” cable length mean?

A2: It is the total length of the permanently attached coaxial cable from the probe tip to the angled connector.

Q3: Can this probe be submerged in oil or coolant?

A3: Yes, with its IP68 rating and stainless-steel construction, it is built to withstand immersion in lubricants and fluids.

Q4: What sensor should I use with this probe?

A4: It is designed to be used with Bently Nevada 3300 XL Proximitor® sensors for optimal performance.

Q5: Is the probe suitable for high-temperature environments?

A5: Yes, it is rated to operate in environments ranging from -35°C up to +177°C.

Q6: How do I verify correct installation depth?

A6: Use a calibrated mechanical spacer tool or a dial indicator to ensure the specified probe-to-target gap.

Q7: Will the probe work if mounted near a magnetic field?

A7: Magnetic fields should be avoided, as they can interfere with eddy current measurements.

Q8: What is the benefit of the 90-degree connector?

A8: It simplifies installation in confined spaces and provides strain relief for cable routing.

Q9: Does the probe require recalibration?

A9: No, once installed with compatible hardware, the system is factory calibrated and does not need field calibration.

Q10: What is the typical lifespan of this probe?

A10: When used within specified limits, the probe typically lasts for years without performance degradation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...