Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

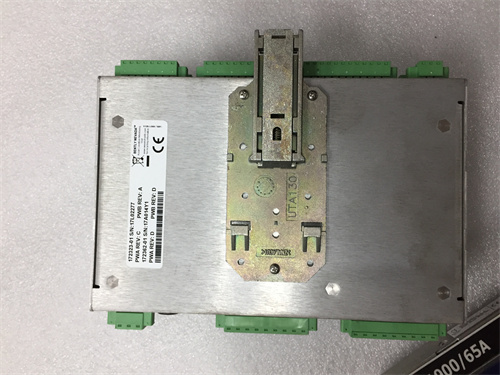

Bently Nevada 3500/25 126398-01 Enhanced Keyphasor Module

Manufacturer:Bently Nevada

Product Number:3500/25 126398-01

Product Type:Enhanced Keyphasor Module

Origin:USA

Dimensions:119.9 x 24.4 x 256.5 mm

Weight:0.34 kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/25 126398-01 Enhanced Keyphasor Module is an essential part of the Bently Nevada 3500 Series—a globally trusted platform for machinery protection and condition monitoring. This module is specifically engineered to provide Keyphasor signals, which are precise timing pulses used to establish the rotational position of a machine’s shaft. These signals are crucial for diagnostics such as phase-triggered vibration analysis, Bode plots, orbital analysis, and rotor balancing.

Unlike standard modules, the 126398-01 version of the Enhanced Keyphasor Module delivers greater flexibility in signal processing, supports multiple channel configurations, and ensures higher fidelity even in environments with high electromagnetic interference. It is ideal for use in critical applications where accurate shaft phase information is vital—such as turbines, compressors, and high-speed rotating machinery in power generation, oil & gas, petrochemical, and marine industries.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Enhanced Keyphasor Module |

| Model Number | 3500/25 |

| Part Number | 126398-01 |

| Function | Provides phase reference pulses (Keyphasor signals) |

| System Compatibility | Bently Nevada 3500 Series |

| Channels Supported | One or two independent or redundant Keyphasor channels |

| Input Sources | Proximity probes, magnetic pickups |

| Input Signal | TTL-compatible square wave or pulse input |

| Signal Conditioning | Internal pulse shaping and filtering |

| Frequency Range | 1 Hz to 20 kHz |

| Pulse Width Range | 10 µs to 500 µs |

| Isolation | Electrical isolation (requires matching isolated I/O card) |

| I/O Module Required | Typically used with 126648-02 or 149369-01 |

| Mounting | Front of 3500 rack |

| Power Supply | Via rack backplane (no external power required) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5%–95% non-condensing |

| Dimensions (W x H x D) | 119.9 x 24.4 x 256.5 mm |

| Weight | 0.34 kg |

| Certifications | CE, UL, CSA, RoHS, ATEX, IECEx |

| Material | Industrial-grade thermoplastic and aluminum casing |

Applications

The 3500/25 126398-01 Enhanced Keyphasor Module is deployed in mission-critical machinery where accurate phase data is required for both real-time protection and advanced diagnostics:

Steam and Gas Turbines

Supports vibration analysis and rotor dynamic studies through synchronized data referencing.

Compressors and Pumps

Essential for condition monitoring, phase imbalance detection, and performance analysis.

Generators and Motors

Used to establish phase relationships for evaluating performance and identifying shaft misalignment.

Oil & Gas Installations

Enables predictive maintenance in compressors, expanders, and rotating separation equipment.

Petrochemical Processing Plants

Supports safety-critical rotating machinery with high-accuracy phase data.

Marine Propulsion Systems

Detects early-stage imbalance or mechanical degradation in engine-driven systems.

Product Advantages

High Signal Fidelity

Captures clean, low-noise phase signals even in environments with high electrical interference.

Redundant Channel Configuration

Offers support for dual-channel redundancy to ensure fault-tolerant operation in critical machinery.

Flexible Sensor Support

Compatible with both proximity probes and magnetic pickups for broad applicability.

Precision Diagnostics

Enables high-resolution orbit plots, Bode plots, and shaft centerline monitoring.

Low Power Consumption

Efficiently draws power from the rack backplane with no need for additional supplies.

Compact and Modular Design

Integrates directly into 3500 Series racks, simplifying installation and maintenance.

Built for Harsh Environments

Certified for ATEX and other industrial safety standards, ideal for offshore and hazardous zones.

Supports High-Speed Equipment

Operates reliably at speeds up to 20,000 RPM, suitable for turbine-class assets.

Frequently Asked Questions (FAQ)

1. What does the 3500/25 126398-01 module do?

It provides precise Keyphasor signals used to determine shaft rotational position for vibration and balance diagnostics.

2. Can it support two separate Keyphasor inputs?

Yes, it can be configured for single or dual channels, including redundant setups for fault tolerance.

3. What types of sensors can be connected?

It supports Bently Nevada proximity probes and magnetic pickups with pulse output.

4. Does this module include signal isolation?

No, but it is designed to work with isolated I/O modules such as 126648-02 for galvanic separation.

5. What’s the maximum frequency it supports?

It can process signals up to 20 kHz, suitable for high-speed rotating machinery.

6. Is software configuration required?

Yes, configuration is typically performed through Bently Nevada’s System 1 software during installation.

7. Can I install this module while the rack is powered?

Hot-swapping is not recommended. It’s best to power down the rack before installation or replacement.

8. How do I know which I/O module to use?

Compatibility depends on application requirements—126648-02 offers isolation, while 149369-01 supports standard setups.

9. Is this module necessary for orbit and Bode plots?

Yes, Keyphasor signals from this module are critical for those diagnostic tools.

10. Can it be used in hazardous environments?

Yes, it meets ATEX, IECEx, and other certifications for use in hazardous and offshore areas.

Bently Nevada 3500/25 126398-01 Enhanced Keyphasor Module

Manufacturer:Bently Nevada

Product Number:3500/25 126398-01

Product Type:Enhanced Keyphasor Module

Origin:USA

Dimensions:119.9 x 24.4 x 256.5 mm

Weight:0.34 kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/25 126398-01 Enhanced Keyphasor Module is an essential part of the Bently Nevada 3500 Series—a globally trusted platform for machinery protection and condition monitoring. This module is specifically engineered to provide Keyphasor signals, which are precise timing pulses used to establish the rotational position of a machine’s shaft. These signals are crucial for diagnostics such as phase-triggered vibration analysis, Bode plots, orbital analysis, and rotor balancing.

Unlike standard modules, the 126398-01 version of the Enhanced Keyphasor Module delivers greater flexibility in signal processing, supports multiple channel configurations, and ensures higher fidelity even in environments with high electromagnetic interference. It is ideal for use in critical applications where accurate shaft phase information is vital—such as turbines, compressors, and high-speed rotating machinery in power generation, oil & gas, petrochemical, and marine industries.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Enhanced Keyphasor Module |

| Model Number | 3500/25 |

| Part Number | 126398-01 |

| Function | Provides phase reference pulses (Keyphasor signals) |

| System Compatibility | Bently Nevada 3500 Series |

| Channels Supported | One or two independent or redundant Keyphasor channels |

| Input Sources | Proximity probes, magnetic pickups |

| Input Signal | TTL-compatible square wave or pulse input |

| Signal Conditioning | Internal pulse shaping and filtering |

| Frequency Range | 1 Hz to 20 kHz |

| Pulse Width Range | 10 µs to 500 µs |

| Isolation | Electrical isolation (requires matching isolated I/O card) |

| I/O Module Required | Typically used with 126648-02 or 149369-01 |

| Mounting | Front of 3500 rack |

| Power Supply | Via rack backplane (no external power required) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5%–95% non-condensing |

| Dimensions (W x H x D) | 119.9 x 24.4 x 256.5 mm |

| Weight | 0.34 kg |

| Certifications | CE, UL, CSA, RoHS, ATEX, IECEx |

| Material | Industrial-grade thermoplastic and aluminum casing |

Applications

The 3500/25 126398-01 Enhanced Keyphasor Module is deployed in mission-critical machinery where accurate phase data is required for both real-time protection and advanced diagnostics:

Steam and Gas Turbines

Supports vibration analysis and rotor dynamic studies through synchronized data referencing.

Compressors and Pumps

Essential for condition monitoring, phase imbalance detection, and performance analysis.

Generators and Motors

Used to establish phase relationships for evaluating performance and identifying shaft misalignment.

Oil & Gas Installations

Enables predictive maintenance in compressors, expanders, and rotating separation equipment.

Petrochemical Processing Plants

Supports safety-critical rotating machinery with high-accuracy phase data.

Marine Propulsion Systems

Detects early-stage imbalance or mechanical degradation in engine-driven systems.

Product Advantages

High Signal Fidelity

Captures clean, low-noise phase signals even in environments with high electrical interference.

Redundant Channel Configuration

Offers support for dual-channel redundancy to ensure fault-tolerant operation in critical machinery.

Flexible Sensor Support

Compatible with both proximity probes and magnetic pickups for broad applicability.

Precision Diagnostics

Enables high-resolution orbit plots, Bode plots, and shaft centerline monitoring.

Low Power Consumption

Efficiently draws power from the rack backplane with no need for additional supplies.

Compact and Modular Design

Integrates directly into 3500 Series racks, simplifying installation and maintenance.

Built for Harsh Environments

Certified for ATEX and other industrial safety standards, ideal for offshore and hazardous zones.

Supports High-Speed Equipment

Operates reliably at speeds up to 20,000 RPM, suitable for turbine-class assets.

Frequently Asked Questions (FAQ)

1. What does the 3500/25 126398-01 module do?

It provides precise Keyphasor signals used to determine shaft rotational position for vibration and balance diagnostics.

2. Can it support two separate Keyphasor inputs?

Yes, it can be configured for single or dual channels, including redundant setups for fault tolerance.

3. What types of sensors can be connected?

It supports Bently Nevada proximity probes and magnetic pickups with pulse output.

4. Does this module include signal isolation?

No, but it is designed to work with isolated I/O modules such as 126648-02 for galvanic separation.

5. What’s the maximum frequency it supports?

It can process signals up to 20 kHz, suitable for high-speed rotating machinery.

6. Is software configuration required?

Yes, configuration is typically performed through Bently Nevada’s System 1 software during installation.

7. Can I install this module while the rack is powered?

Hot-swapping is not recommended. It’s best to power down the rack before installation or replacement.

8. How do I know which I/O module to use?

Compatibility depends on application requirements—126648-02 offers isolation, while 149369-01 supports standard setups.

9. Is this module necessary for orbit and Bode plots?

Yes, Keyphasor signals from this module are critical for those diagnostic tools.

10. Can it be used in hazardous environments?

Yes, it meets ATEX, IECEx, and other certifications for use in hazardous and offshore areas.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...