Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

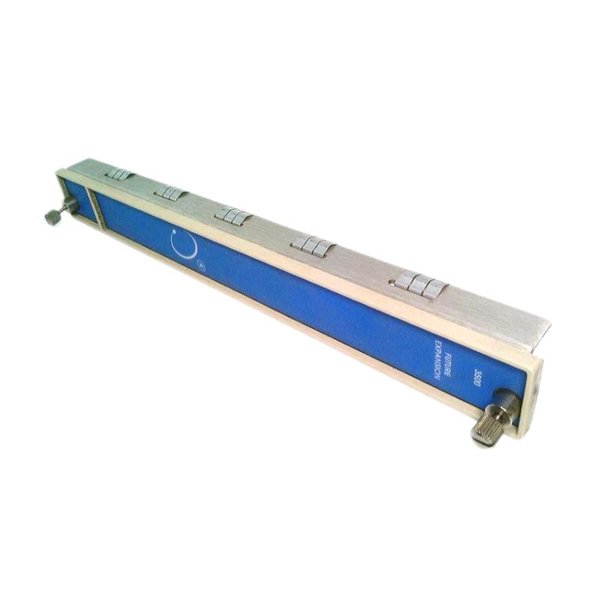

Bently Nevada 128275-01 3500 Future Expansion Panel

Manufacturer:Bently Nevada

Product Number:128275-01

Product Type:3500 Future Expansion Panel

Origin:USA

Dimensions:241 × 50 × 200 mm

Weight:0.045 kg

Views:96

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 128275-01 is a Communication Gateway Module specifically designed for the 3500 Series Machinery Protection System. This module acts as an interface between the monitoring system and external control systems, enabling seamless data transmission via industry-standard communication protocols such as Modbus, Ethernet, and Serial communication.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 128275-01 |

| Manufacturer | Bently Nevada |

| Function | Communication Gateway Module |

| Supported System | 3500 Series Machinery Protection System |

| Communication Protocols | Modbus, Ethernet, Serial |

| Power Supply | 24 VDC |

| Baud Rate | Up to 115.2 kbps |

| Operating Temperature | -30°C to +70°C |

| Humidity | 5% – 95% (Non-condensing) |

| Mounting | Rack-based |

| Material | Industrial-grade components |

| Dimensions | 241 × 50 × 200 mm |

| Weight |

0.045 kg |

This module is essential in industries requiring real-time condition monitoring, providing reliable data acquisition and transmission to SCADA, DCS, and other process automation systems. It ensures accurate reporting and timely alerts for maintenance teams, helping to prevent equipment failures and reduce operational risks.

With a robust design and high-speed communication capabilities, the Bently Nevada 128275-01 module enhances the reliability and efficiency of industrial monitoring systems, ensuring that critical machinery operates smoothly under varying environmental conditions.

Applications

The Bently Nevada 128275-01 module is widely used in industries that require high-precision machine condition monitoring and data communication. Specific applications include:

- Oil & Gas Industry – Used in refineries, offshore platforms, and pipelines for remote condition monitoring.

- Power Generation – Essential for monitoring turbines and generators in thermal, hydro, and nuclear power plants.

- Manufacturing Industry – Ensures real-time monitoring of production line equipment.

- Steel and Metal Processing – Used in heavy machinery monitoring and predictive maintenance.

- Aerospace & Defense – Applied in aerospace testing facilities for critical component monitoring.

- Chemical and Petrochemical Plants – Facilitates secure communication in hazardous environments.

- Automotive Industry – Supports industrial robotics and automated assembly lines.

- Pharmaceutical Industry – Ensures compliance with stringent monitoring requirements.

- Mining Operations – Used in underground and surface mining equipment monitoring.

- Marine and Shipping – Helps in engine performance monitoring on cargo and naval vessels.

Product Advantages

The Bently Nevada 128275-01 module offers multiple benefits, making it a preferred choice for industrial communication needs:

- High-Speed Data Transmission – Supports fast and secure data exchange for real-time monitoring.

- Multi-Protocol Support – Compatible with Modbus, Ethernet, and Serial communication.

- Seamless Integration – Easily integrates with SCADA, DCS, and PLC systems.

- Reliable Performance – Designed to function in extreme environmental conditions.

- Compact and Lightweight – Optimized for rack-mount installation without occupying excessive space.

- Minimal Downtime – Ensures continuous operation with redundant power supply options.

- Improved Equipment Lifespan – Helps in early fault detection and preventive maintenance.

- Advanced Security Features – Protects data integrity with industrial-grade encryption.

- User-Friendly Configuration – Supports easy setup and parameter adjustments.

- Low Maintenance Requirement – Engineered for long operational life with minimal servicing.

Latest News & Updates

- “Bently Nevada 128275-01 Enhances Industrial Communication for Condition Monitoring” – Case studies highlight its effectiveness in predictive maintenance.

- “New Firmware Update Released for Bently Nevada 128275-01” – Enhancements in data security and compatibility.

- “Oil & Gas Sector Adopts Bently Nevada Communication Modules for Remote Monitoring” – Improved reliability in offshore platforms.

- “Integration of Bently Nevada 128275-01 with Modern SCADA Systems” – A step toward Industry 4.0.

- “Bently Nevada Expands Support for Cloud-Based Industrial Data Solutions” – Increasing efficiency in plant-wide monitoring.

Frequently Asked Questions (FAQs)

What communication protocols does the 128275-01 module support?

It supports Modbus, Ethernet, and Serial communication, ensuring compatibility with various industrial systems.

Can this module be used in hazardous environments?

Yes, it is designed to operate in industries like oil & gas, petrochemical, and mining, where hazardous conditions are common.

What are the dimensions and weight of the module?

The module measures 241 × 50 × 200 mm and weighs 0.045 kg.

How does this module improve machine reliability?

It provides real-time data transmission, allowing early detection of potential failures and enabling proactive maintenance.

What power supply does this module require?

It operates on a 24 VDC power supply.

Does this module support redundant power configurations?

Yes, it allows redundant power inputs to ensure continuous operation.

How is this module installed in a 3500 rack?

It is designed for rack-based installation and integrates seamlessly with other 3500 Series components.

What is the maximum baud rate supported?

The module supports baud rates up to 115.2 kbps.

Is this module compatible with third-party monitoring systems?

Yes, it can be integrated with various DCS, SCADA, and PLC systems.

How often does the module require maintenance?

It is designed for long-term operation with minimal maintenance requirements.

Bently Nevada 128275-01 3500 Future Expansion Panel

Manufacturer:Bently Nevada

Product Number:128275-01

Product Type:3500 Future Expansion Panel

Origin:USA

Dimensions:241 × 50 × 200 mm

Weight:0.045 kg

Views:96

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 128275-01 is a Communication Gateway Module specifically designed for the 3500 Series Machinery Protection System. This module acts as an interface between the monitoring system and external control systems, enabling seamless data transmission via industry-standard communication protocols such as Modbus, Ethernet, and Serial communication.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 128275-01 |

| Manufacturer | Bently Nevada |

| Function | Communication Gateway Module |

| Supported System | 3500 Series Machinery Protection System |

| Communication Protocols | Modbus, Ethernet, Serial |

| Power Supply | 24 VDC |

| Baud Rate | Up to 115.2 kbps |

| Operating Temperature | -30°C to +70°C |

| Humidity | 5% – 95% (Non-condensing) |

| Mounting | Rack-based |

| Material | Industrial-grade components |

| Dimensions | 241 × 50 × 200 mm |

| Weight |

0.045 kg |

This module is essential in industries requiring real-time condition monitoring, providing reliable data acquisition and transmission to SCADA, DCS, and other process automation systems. It ensures accurate reporting and timely alerts for maintenance teams, helping to prevent equipment failures and reduce operational risks.

With a robust design and high-speed communication capabilities, the Bently Nevada 128275-01 module enhances the reliability and efficiency of industrial monitoring systems, ensuring that critical machinery operates smoothly under varying environmental conditions.

Applications

The Bently Nevada 128275-01 module is widely used in industries that require high-precision machine condition monitoring and data communication. Specific applications include:

- Oil & Gas Industry – Used in refineries, offshore platforms, and pipelines for remote condition monitoring.

- Power Generation – Essential for monitoring turbines and generators in thermal, hydro, and nuclear power plants.

- Manufacturing Industry – Ensures real-time monitoring of production line equipment.

- Steel and Metal Processing – Used in heavy machinery monitoring and predictive maintenance.

- Aerospace & Defense – Applied in aerospace testing facilities for critical component monitoring.

- Chemical and Petrochemical Plants – Facilitates secure communication in hazardous environments.

- Automotive Industry – Supports industrial robotics and automated assembly lines.

- Pharmaceutical Industry – Ensures compliance with stringent monitoring requirements.

- Mining Operations – Used in underground and surface mining equipment monitoring.

- Marine and Shipping – Helps in engine performance monitoring on cargo and naval vessels.

Product Advantages

The Bently Nevada 128275-01 module offers multiple benefits, making it a preferred choice for industrial communication needs:

- High-Speed Data Transmission – Supports fast and secure data exchange for real-time monitoring.

- Multi-Protocol Support – Compatible with Modbus, Ethernet, and Serial communication.

- Seamless Integration – Easily integrates with SCADA, DCS, and PLC systems.

- Reliable Performance – Designed to function in extreme environmental conditions.

- Compact and Lightweight – Optimized for rack-mount installation without occupying excessive space.

- Minimal Downtime – Ensures continuous operation with redundant power supply options.

- Improved Equipment Lifespan – Helps in early fault detection and preventive maintenance.

- Advanced Security Features – Protects data integrity with industrial-grade encryption.

- User-Friendly Configuration – Supports easy setup and parameter adjustments.

- Low Maintenance Requirement – Engineered for long operational life with minimal servicing.

Latest News & Updates

- “Bently Nevada 128275-01 Enhances Industrial Communication for Condition Monitoring” – Case studies highlight its effectiveness in predictive maintenance.

- “New Firmware Update Released for Bently Nevada 128275-01” – Enhancements in data security and compatibility.

- “Oil & Gas Sector Adopts Bently Nevada Communication Modules for Remote Monitoring” – Improved reliability in offshore platforms.

- “Integration of Bently Nevada 128275-01 with Modern SCADA Systems” – A step toward Industry 4.0.

- “Bently Nevada Expands Support for Cloud-Based Industrial Data Solutions” – Increasing efficiency in plant-wide monitoring.

Frequently Asked Questions (FAQs)

What communication protocols does the 128275-01 module support?

It supports Modbus, Ethernet, and Serial communication, ensuring compatibility with various industrial systems.

Can this module be used in hazardous environments?

Yes, it is designed to operate in industries like oil & gas, petrochemical, and mining, where hazardous conditions are common.

What are the dimensions and weight of the module?

The module measures 241 × 50 × 200 mm and weighs 0.045 kg.

How does this module improve machine reliability?

It provides real-time data transmission, allowing early detection of potential failures and enabling proactive maintenance.

What power supply does this module require?

It operates on a 24 VDC power supply.

Does this module support redundant power configurations?

Yes, it allows redundant power inputs to ensure continuous operation.

How is this module installed in a 3500 rack?

It is designed for rack-based installation and integrates seamlessly with other 3500 Series components.

What is the maximum baud rate supported?

The module supports baud rates up to 115.2 kbps.

Is this module compatible with third-party monitoring systems?

Yes, it can be integrated with various DCS, SCADA, and PLC systems.

How often does the module require maintenance?

It is designed for long-term operation with minimal maintenance requirements.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...