Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

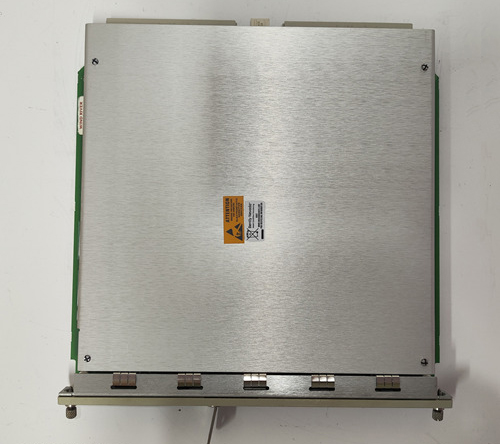

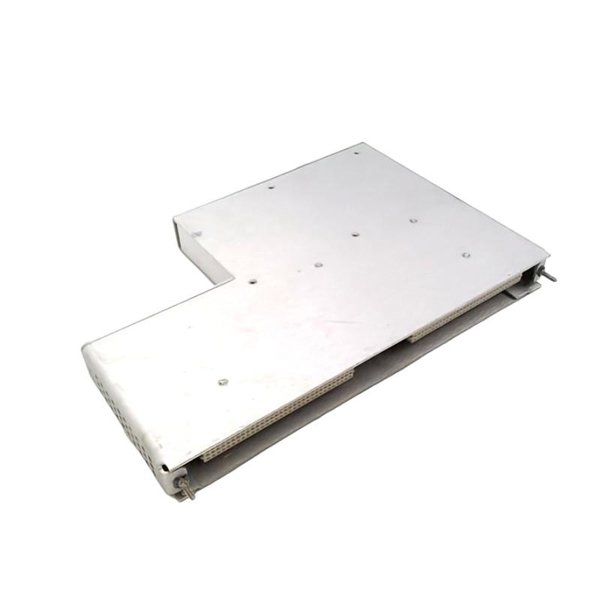

Bently Nevada 3500/60 136711-01 I/O Module with Internal Barriers and Internal Terminations

Manufacturer:Bently Nevada

Product Number:3500/60 136711-01

Product Type:I/O Module with Internal Barriers and Internal Terminations

Origin:USA

Dimensions:241.3 x 24.4 x 163.1 mm

Weight:0.46 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/60 136711-01 I/O Module is a specialized input/output module designed for use within the Bently Nevada 3500 Machinery Protection System. It incorporates internal barriers and internal terminations, making it suitable for hazardous area applications while simplifying wiring requirements. The integrated barriers provide intrinsic safety by limiting energy levels to field devices, ensuring safe operation in explosive environments.

This module supports the 3500/60 Temperature Monitor, which measures multiple thermocouple and RTD inputs for critical machinery and process monitoring. By combining electrical isolation, barrier protection, and convenient termination within a single module, it reduces system complexity, installation time, and maintenance overhead.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 3500/60 136711-01 |

| Series | Bently Nevada 3500 Machinery Protection System |

| Module Type | I/O Module with Internal Barriers & Internal Terminations |

| Compatible Monitor | 3500/60 Temperature Monitor |

| Inputs Supported | RTD (2-wire, 3-wire, 4-wire), Thermocouples (J, K, E, T, B, R, S, N) |

| Signal Isolation | Galvanic isolation between field devices and system electronics |

| Barriers | Intrinsic safety barriers for hazardous area compliance |

| Terminations | Internal screw terminal block |

| Power Supply | Powered via 3500 rack backplane |

| Operating Temperature | -30 °C to +65 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | Up to 95% non-condensing |

| Shock / Vibration | Meets IEC and industrial standards |

| Diagnostic Features | Continuous self-test, fault indication |

| Dimensions | 241.3 x 24.4 x 163.1 mm |

| Weight | 0.46 kg |

| Mounting | Rear slot mounting in 3500 rack |

| Certifications | CE, CSA, ATEX, IECEx (varies by configuration) |

Product Applications

The 3500/60 136711-01 I/O Module is primarily used in conjunction with the Temperature Monitor to provide safe, reliable, and accurate monitoring in industrial environments. Key applications include:

Temperature Monitoring in Turbomachinery – Steam turbines, gas turbines, and compressors.

Hazardous Area Installations – Facilities requiring intrinsic safety compliance.

Generators and Motors – Winding and bearing temperature monitoring.

Process Equipment – Reactors, boilers, and heat exchangers.

Oil & Gas Facilities – Refineries, LNG plants, and offshore platforms.

Petrochemical and Power Plants – Continuous safety-critical operations.

Product Advantages

Intrinsic Safety: Built-in barriers provide safe operation in hazardous environments.

Simplified Installation: Internal terminations reduce wiring effort and potential errors.

High Accuracy: Supports multiple RTDs and thermocouples for precise measurements.

System Reliability: Continuous diagnostics and fault reporting improve uptime.

Seamless Compatibility: Designed to work directly with the 3500/60 Temperature Monitor.

Reduced Footprint: Combines barrier protection and terminations within a single module.

Proven Durability: Engineered for mission-critical machinery protection systems.

FAQ

What types of sensors are supported by the 3500/60 I/O Module?

It supports RTDs (2-, 3-, and 4-wire) and multiple thermocouple types (J, K, E, T, B, R, S, N).

How does the internal barrier function improve safety?

The barrier limits voltage and current to intrinsically safe levels, preventing ignition in hazardous areas.

Can this module be used in both safe and hazardous zones?

Yes, it is designed for intrinsic safety applications but can also be used in non-hazardous environments.

How many channels does the 3500/60 Temperature Monitor support through this module?

Typically, up to 12 RTD or thermocouple inputs can be connected per monitor.

Does the I/O module provide galvanic isolation?

Yes, it provides isolation between the field wiring and the rack electronics.

Can the module detect open or shorted sensors?

Yes, diagnostic functions detect sensor failures and generate system alarms.

Is the I/O module hot-swappable?

Yes, it can be replaced without powering down the rack, reducing downtime.

What kind of diagnostic data does it provide?

It continuously monitors input channels and reports wiring faults, sensor errors, and barrier issues.

Does the I/O module require external barriers?

No, because internal barriers are integrated, eliminating the need for separate barrier assemblies.

How does it interface with System 1 software?

The I/O module works with the 3500/60 Monitor, which communicates data to System 1 for condition monitoring.

Bently Nevada 3500/60 136711-01 I/O Module with Internal Barriers and Internal Terminations

Manufacturer:Bently Nevada

Product Number:3500/60 136711-01

Product Type:I/O Module with Internal Barriers and Internal Terminations

Origin:USA

Dimensions:241.3 x 24.4 x 163.1 mm

Weight:0.46 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/60 136711-01 I/O Module is a specialized input/output module designed for use within the Bently Nevada 3500 Machinery Protection System. It incorporates internal barriers and internal terminations, making it suitable for hazardous area applications while simplifying wiring requirements. The integrated barriers provide intrinsic safety by limiting energy levels to field devices, ensuring safe operation in explosive environments.

This module supports the 3500/60 Temperature Monitor, which measures multiple thermocouple and RTD inputs for critical machinery and process monitoring. By combining electrical isolation, barrier protection, and convenient termination within a single module, it reduces system complexity, installation time, and maintenance overhead.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 3500/60 136711-01 |

| Series | Bently Nevada 3500 Machinery Protection System |

| Module Type | I/O Module with Internal Barriers & Internal Terminations |

| Compatible Monitor | 3500/60 Temperature Monitor |

| Inputs Supported | RTD (2-wire, 3-wire, 4-wire), Thermocouples (J, K, E, T, B, R, S, N) |

| Signal Isolation | Galvanic isolation between field devices and system electronics |

| Barriers | Intrinsic safety barriers for hazardous area compliance |

| Terminations | Internal screw terminal block |

| Power Supply | Powered via 3500 rack backplane |

| Operating Temperature | -30 °C to +65 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | Up to 95% non-condensing |

| Shock / Vibration | Meets IEC and industrial standards |

| Diagnostic Features | Continuous self-test, fault indication |

| Dimensions | 241.3 x 24.4 x 163.1 mm |

| Weight | 0.46 kg |

| Mounting | Rear slot mounting in 3500 rack |

| Certifications | CE, CSA, ATEX, IECEx (varies by configuration) |

Product Applications

The 3500/60 136711-01 I/O Module is primarily used in conjunction with the Temperature Monitor to provide safe, reliable, and accurate monitoring in industrial environments. Key applications include:

Temperature Monitoring in Turbomachinery – Steam turbines, gas turbines, and compressors.

Hazardous Area Installations – Facilities requiring intrinsic safety compliance.

Generators and Motors – Winding and bearing temperature monitoring.

Process Equipment – Reactors, boilers, and heat exchangers.

Oil & Gas Facilities – Refineries, LNG plants, and offshore platforms.

Petrochemical and Power Plants – Continuous safety-critical operations.

Product Advantages

Intrinsic Safety: Built-in barriers provide safe operation in hazardous environments.

Simplified Installation: Internal terminations reduce wiring effort and potential errors.

High Accuracy: Supports multiple RTDs and thermocouples for precise measurements.

System Reliability: Continuous diagnostics and fault reporting improve uptime.

Seamless Compatibility: Designed to work directly with the 3500/60 Temperature Monitor.

Reduced Footprint: Combines barrier protection and terminations within a single module.

Proven Durability: Engineered for mission-critical machinery protection systems.

FAQ

What types of sensors are supported by the 3500/60 I/O Module?

It supports RTDs (2-, 3-, and 4-wire) and multiple thermocouple types (J, K, E, T, B, R, S, N).

How does the internal barrier function improve safety?

The barrier limits voltage and current to intrinsically safe levels, preventing ignition in hazardous areas.

Can this module be used in both safe and hazardous zones?

Yes, it is designed for intrinsic safety applications but can also be used in non-hazardous environments.

How many channels does the 3500/60 Temperature Monitor support through this module?

Typically, up to 12 RTD or thermocouple inputs can be connected per monitor.

Does the I/O module provide galvanic isolation?

Yes, it provides isolation between the field wiring and the rack electronics.

Can the module detect open or shorted sensors?

Yes, diagnostic functions detect sensor failures and generate system alarms.

Is the I/O module hot-swappable?

Yes, it can be replaced without powering down the rack, reducing downtime.

What kind of diagnostic data does it provide?

It continuously monitors input channels and reports wiring faults, sensor errors, and barrier issues.

Does the I/O module require external barriers?

No, because internal barriers are integrated, eliminating the need for separate barrier assemblies.

How does it interface with System 1 software?

The I/O module works with the 3500/60 Monitor, which communicates data to System 1 for condition monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...